High-purity aluminum powder preparation equipment and method for preparing high-purity aluminum powder by same

An aluminum powder, high-purity technology, applied in the field of aluminum powder production equipment, can solve the problems of high cost, long production process route, poor control of purity and production quality, etc., and achieves low cost, no environmental pollution, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

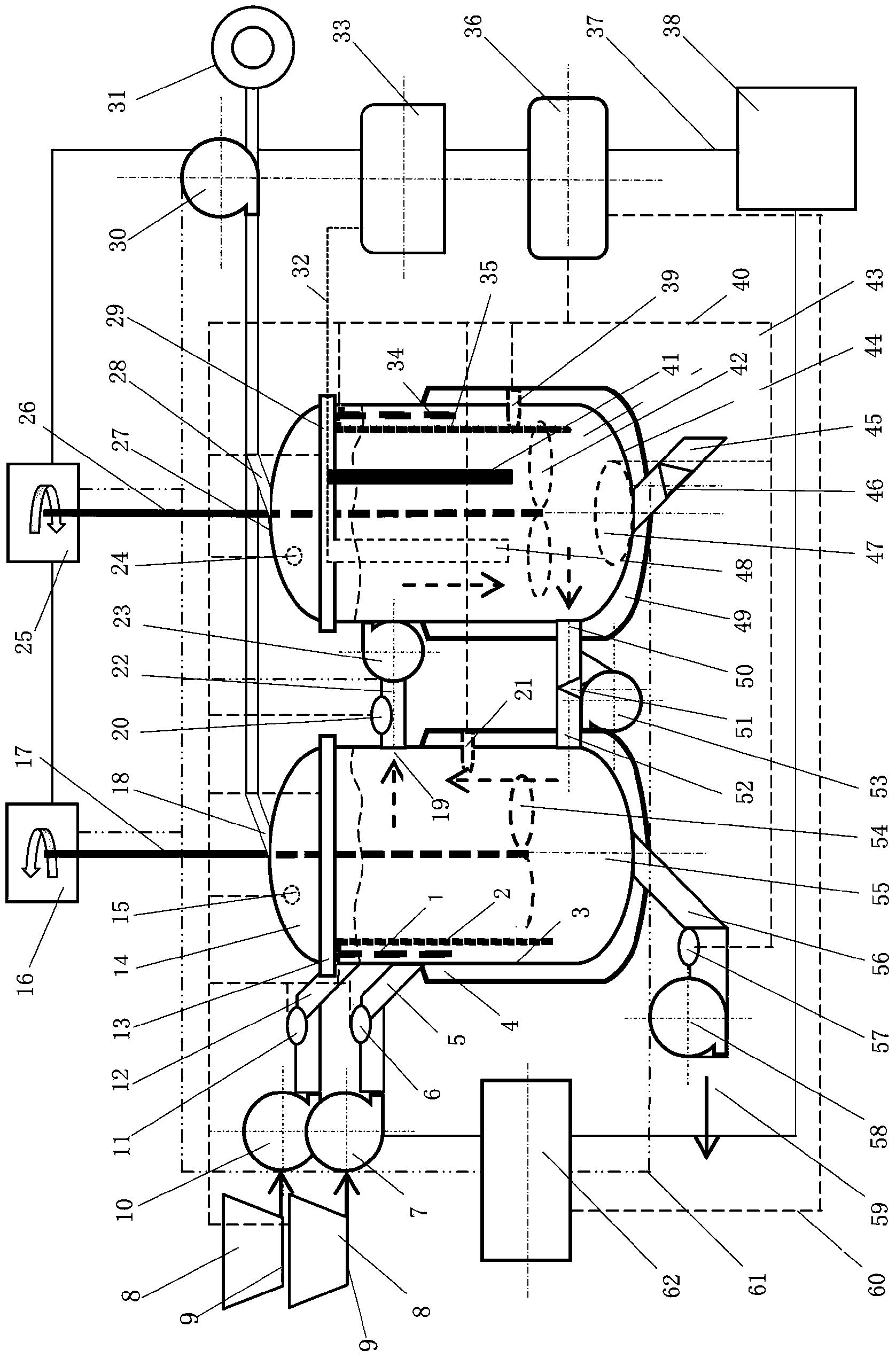

[0083] Embodiment 2 is another embodiment of the present invention, such as figure 1 As shown, when the circulating fluid 55 and the deposition fluid (i.e., the working fluid 43) share a reactor body, the powder production equipment can be simplified from a double reactor body to a single reactor body structure. Although the operating efficiency of the equipment is not as high as that of the double reactor body, the single reactor body The bulk powder preparation equipment has a simple structure and low cost;

[0084] High-purity aluminum powder production equipment, including:

[0085] Two feeding bins 8 are used to store organic halogenated salt and aluminum chloride raw materials, and each bin is equipped with a level sensor 9;

[0086] Two feeding pumps (7 and 10) are used to pump the raw materials in the feeding bin to the circulating tank body 3. When preparing the working fluid 43 or the circulating fluid 55 for circulation, in response to the command of the automatic ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap