A washing machine capable of washing down jackets

A technology for washing machines and down jackets, applied in the field of washing machines, can solve the problems of clothes floating in a tub and the washing effect is reduced, and achieve the effects of saving water consumption, quickly and completely soaking, and improving the washing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

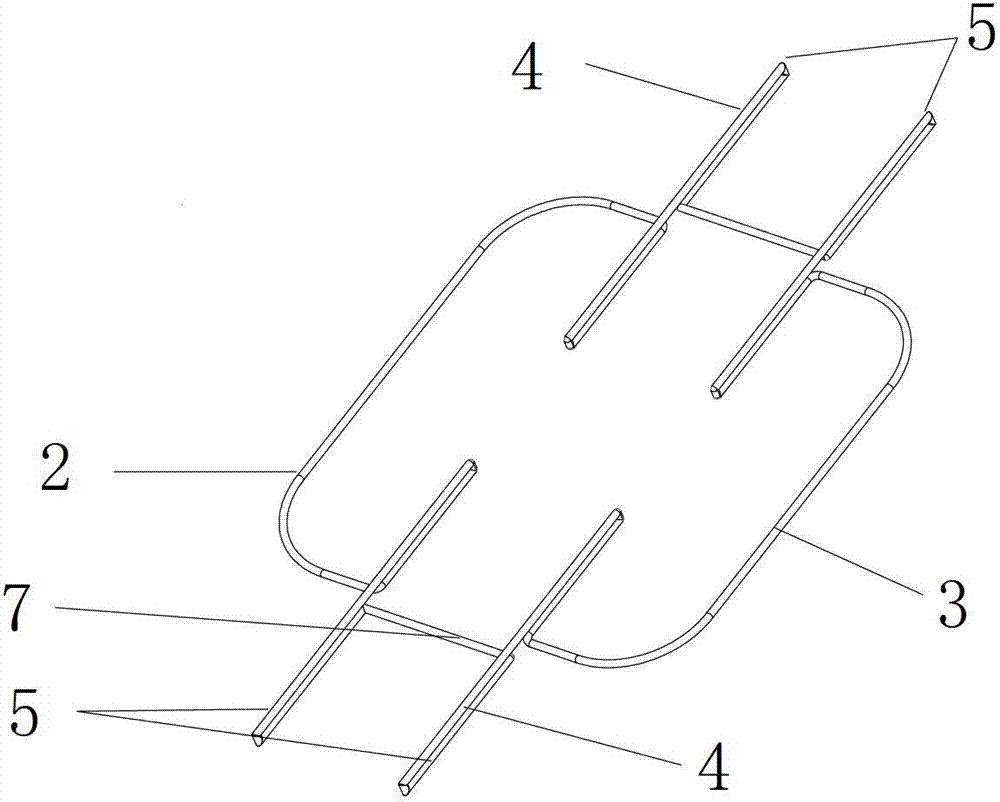

[0033] In this embodiment: when the insertion end 4 is a group (not shown in the figure, only the Figures 1 to 3 The first insertion end is used as this embodiment), the main body 3 is set as a circular frame, and the two insertion rods 5 of the insertion end 4 are parallel to the same diameter of the oval frame, and this diameter is used as the axis of symmetry. The diameter is less than the diameter of the washing machine inner barrel 11, greater than or equal to the inner diameter of the balance ring 6 of the washing machine, and the diameter is greater than the outer diameter of the wave wheel of the washing machine.

[0034] On the insertion end 4, near the connection between the insertion end 4 and the main body 3, there is an elastic device 7 for elastically deforming the distance between the two insertion rods 5. The elastic device 7 is a shrapnel device or a spring connecting the two insertion rods. device. Pinch the two plug-in rods 5 at the insertion end with your...

Embodiment 2

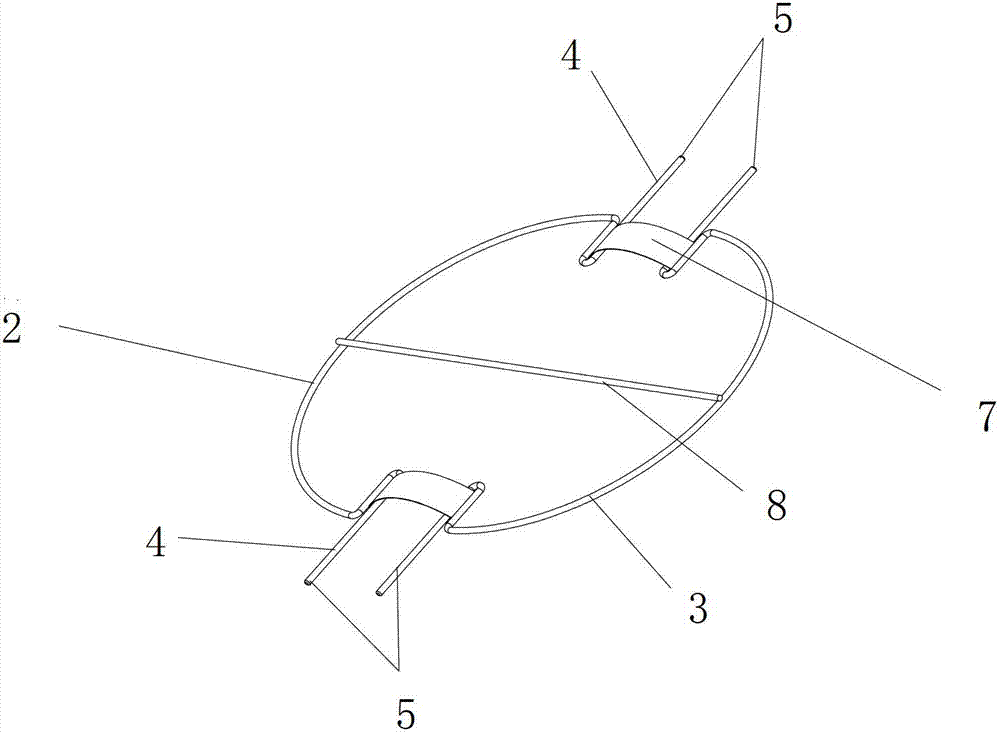

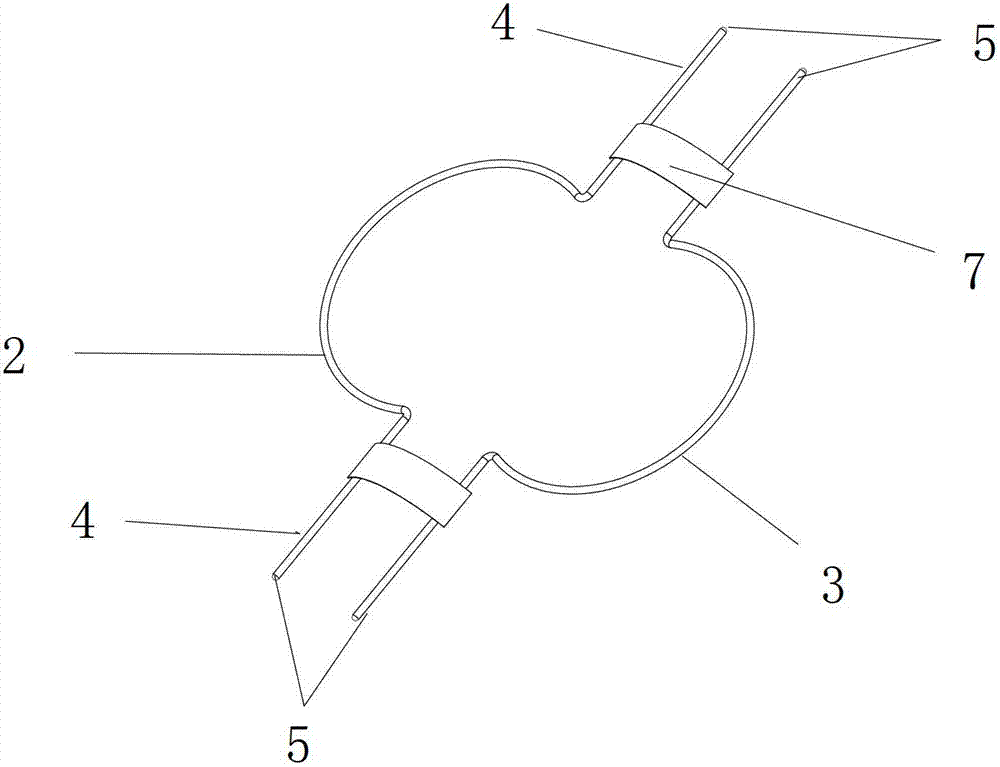

[0042] Such as figure 1As shown, in this embodiment: the insertion ends 4 are two groups, arranged on the side of the main body 3, each group of insertion ends 4 is two insertion rods 5 parallel to the centerline of the main body 3, and the two insertion rods 5 are symmetrical Distributed on both sides of the midline of the main body 3. The main body 3 is set as an elliptical frame or a circular frame. When the main body 3 is an elliptical frame: the two insertion rods 5 of the insertion end 4 are parallel to the major diameter of the elliptical frame, and are set with the major diameter as the axis of symmetry. The major diameter of the elliptical frame is less than The diameter of the washing machine inner tub 11 is greater than or equal to the inner diameter of the balancing ring 6 of the washing machine, and the short diameter is less than or equal to the inner diameter of the balancing ring 6 of the washing machine and greater than the outer diameter of the wave wheel of ...

Embodiment 3

[0050] Such as figure 1 As shown, in this embodiment: the insertion ends 4 are two groups, arranged on the side of the main body 3, each group of insertion ends 4 is two insertion rods 5 parallel to the centerline of the main body 3, and the two insertion rods 5 are symmetrical Distributed on both sides of the midline of the main body 3. The main body 3 is set as an elliptical frame or a circular frame. When the main body 3 is an elliptical frame: the two insertion rods 5 of the insertion end 4 are parallel to the major diameter of the elliptical frame, and are set with the major diameter as the axis of symmetry. The major diameter of the elliptical frame is less than The diameter of the washing machine inner tub 11 is greater than or equal to the inner diameter of the balancing ring 6 of the washing machine, and the short diameter is less than or equal to the inner diameter of the balancing ring 6 of the washing machine and greater than the outer diameter of the wave wheel of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com