Building fabricated type integrated framework

A prefabricated and architectural technology, applied in the direction of building, building structure, scaffolding connection, etc., can solve the problems of the replacement, upgrade and application field expansion of the constrained integrated frame, so as to reduce the assembly workload and balance the force. , the effect of reducing the cost of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

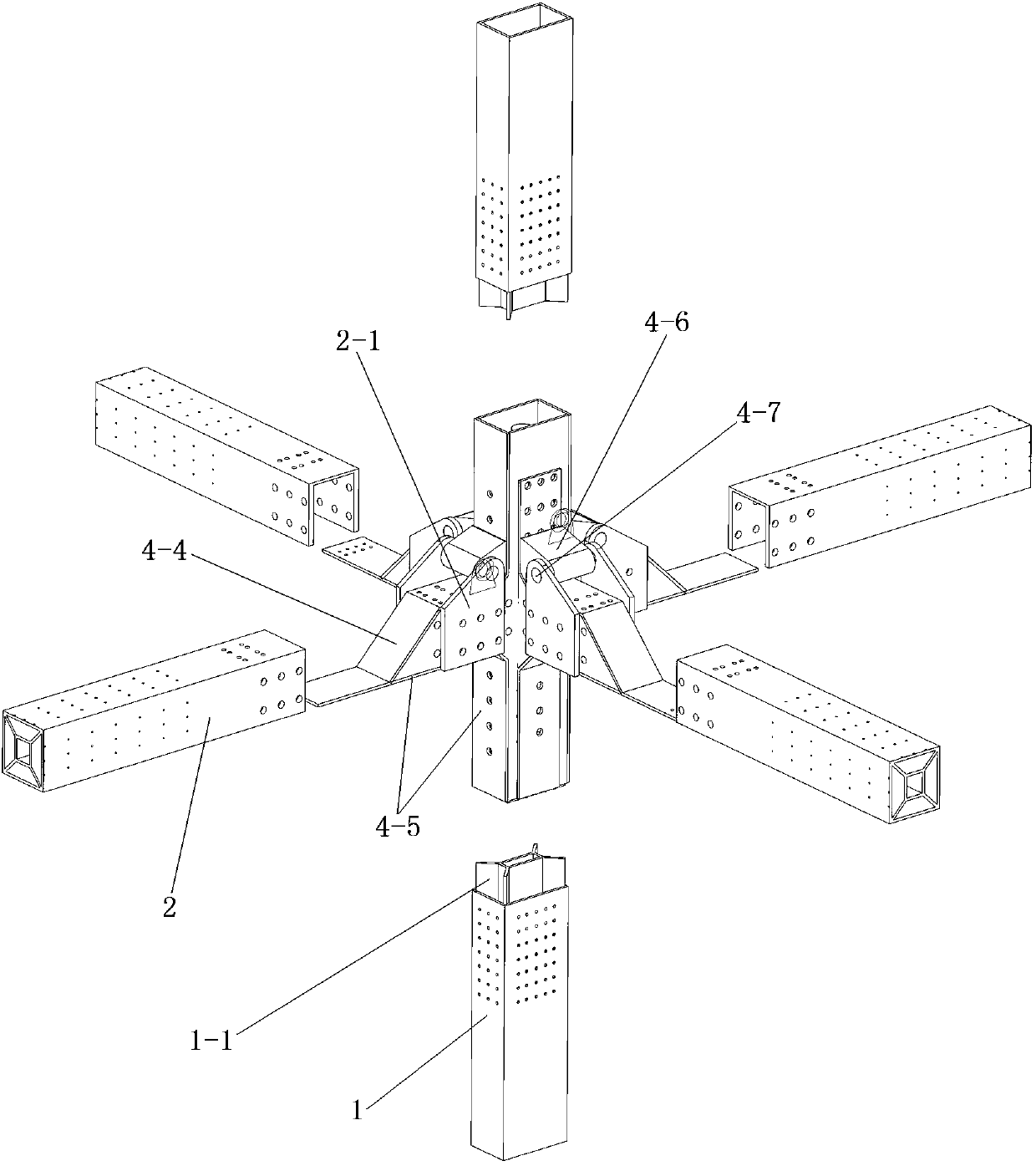

[0037] refer to figure 1, the integrated frame of the invention includes: upright column 1, cross beam 2, diagonal support 3, beam-column node member 4 connecting the intersection point of beam and column, connecting point of diagonal support and beam or column, connecting diagonal support and beam or column Diagonal support node member 5.

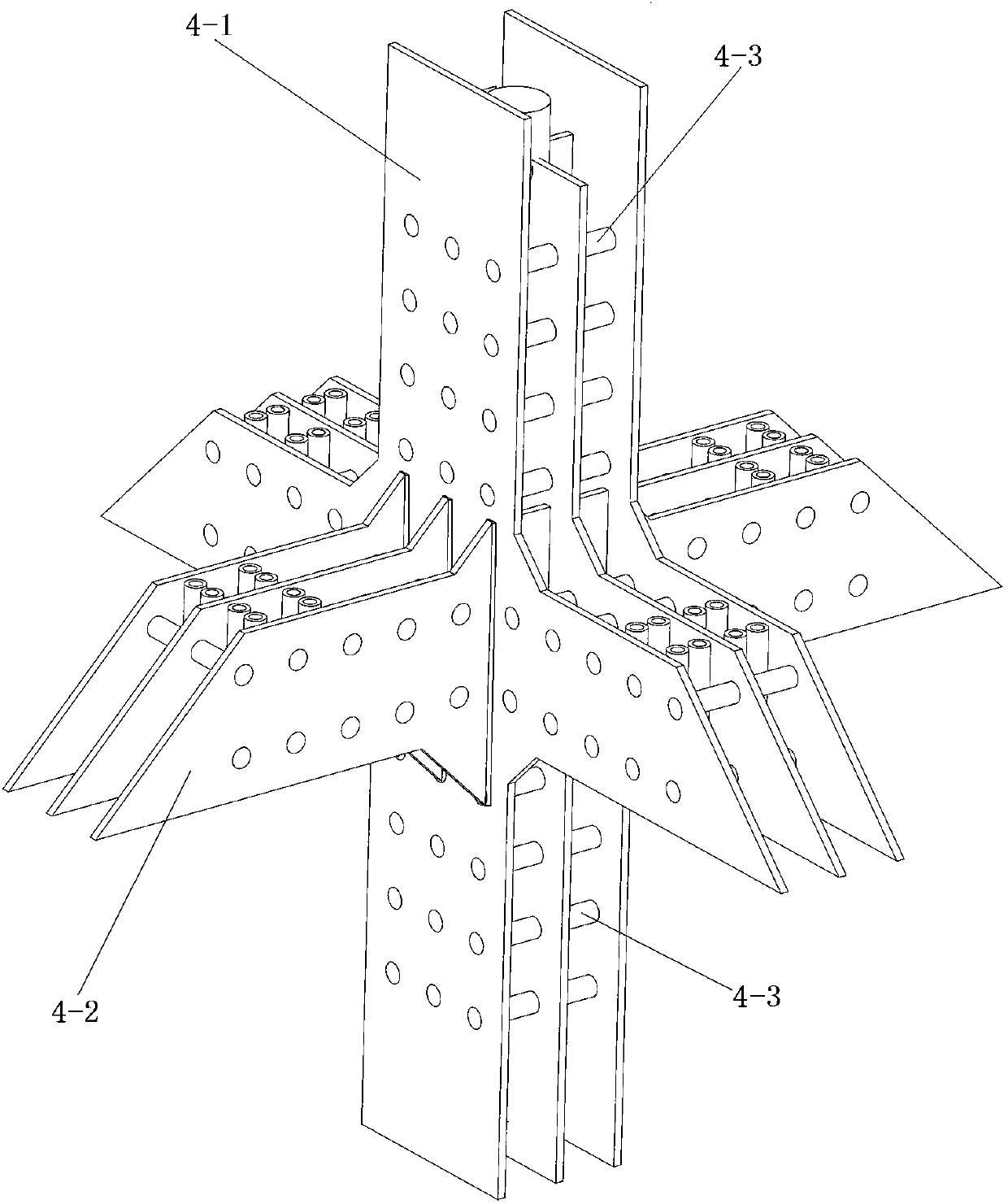

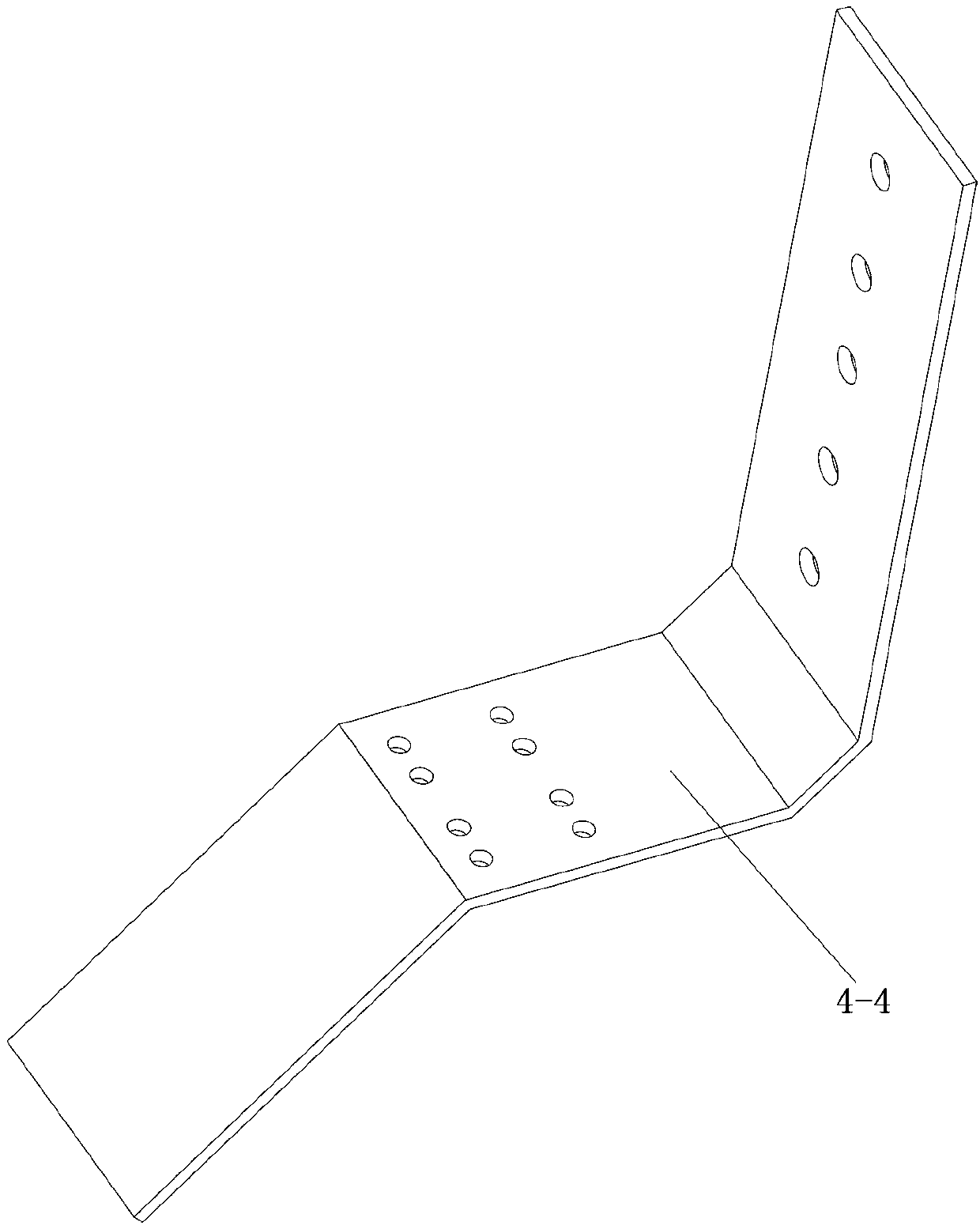

[0038] refer to figure 2 , the beam-column node component 4 is composed of a group (three pieces) of cross-shaped main boards 4-1 and a group (three pieces) of inline-shaped insert boards 4-2 that run through the cross-shaped main board group to form a node cross three-dimensional body, wherein, The length direction of the strip hole for assembling the plug-in board 4-2 on the main board 4-1 is in the vertical direction of the cross, and the main board and the plug-in board are welded and connected at the intersection of the main board 4-1 and the plug-in board 4-2 that can be welded. The cross-shaped upper and lower ends of the group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com