Method for preparing rapeseed protein concentrates and phytate acid by deep processing rape cake

The technology of rapeseed protein concentrate and rapeseed meal is applied in the directions of protein composition of vegetable seeds, chemical instruments and methods, protein food ingredients, etc., and achieves the effects of cost saving, remarkable economic benefit and good palatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

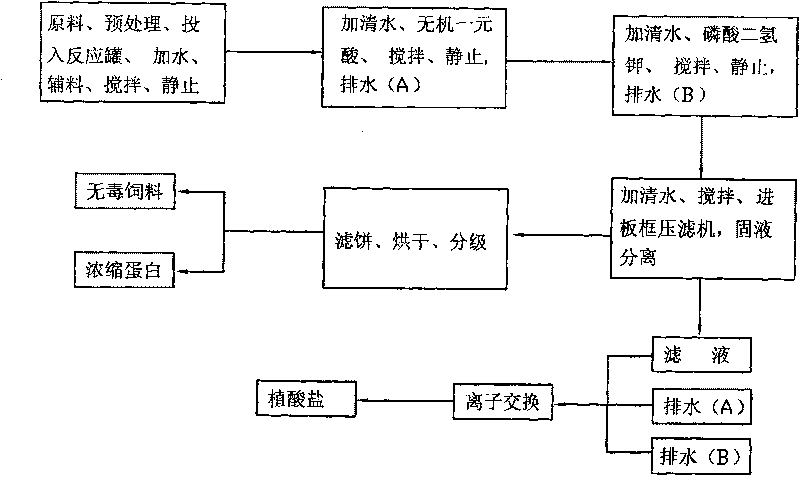

[0033] Example 1: The rapeseed cake is removed and pulverized to a fineness within 10 meshes, and quantitatively (2-2.5 tons) is added to the reaction tank, and 0.6% of calcium chloride, 10% of hydrochloric acid, and 4 times of hot water at 65°C are added. Stir fully for 20 minutes, then stand still for 15 minutes, then add 4 times of cold water, stir fully for 30 minutes, stand still for 10 minutes, then filter and drain through the filter tank, and the discharged filtrate is subjected to ion exchange adsorption after simple sedimentation to obtain phytic acid The water sample is then concentrated under reduced pressure to obtain a phytic acid water sample with a concentration of about 20%, then transferred to a crystallization tank for crystallization, the solid-liquid mixture after crystallization is centrifuged, and the separated solid is recrystallized with deionized water. Finally, centrifuge, dry, and crush to obtain a phytic acid product with a fineness of less than 100...

example 2

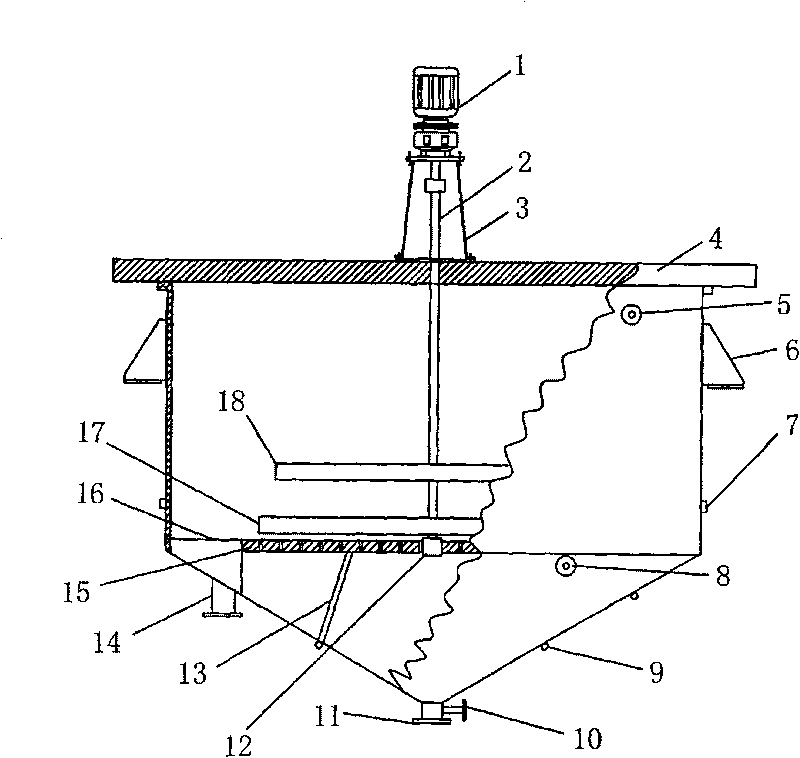

[0034] Example 2: After the rapeseed cake is removed and crushed, the metal contained in the rapeseed cake and the agglomerated rapeseed cake are crushed, and the fineness is within 10 meshes, and added to the reaction tank. By adding 50-80°C hot water, adding calcium chloride accounting for 0.1-1% of the raw material rapeseed cake, hydrochloric acid accounting for 5-10% of the raw material, and phosphate accounting for 0.2-1% of the raw material, the self-developed vegetable Seed detoxification reaction Stir filter tank for full reaction, discharge liquid, then add 2 to 6 times of water to filter through plate and frame filter press, filter cake is dried by pulse type two-stage airflow dryer, and then graded and screened by high square sieve The rapeseed protein concentrate is obtained, and the extracted water sample is extracted by ion exchange to extract phytic acid, and then purified by crystallization and recrystallization to obtain phytic acid with higher purity.

example 3

[0035]Example 3: The rapeseed cake is removed and crushed to within 10 meshes; quantitatively (2 tons) is added to the reaction tank, 8 tons of hot water at 50-80°C, and 1 kg of calcium chloride are added (the ratio is the raw material rapeseed cake 0.1% to 1% of the meal); fully stir for 15 minutes, and let stand for 10 minutes; add 8 tons of clear water (adding water for the second time), 160 kg of hydrochloric acid (the ratio is 5% to 10% of the raw rapeseed cake), and fully stir for 15 minutes. minute, stand still for 10 minutes; stir for another 15 minutes, stand still for 10 minutes; open the drain port at the bottom of the reaction tank, and the water containing glucosinolate glucoside, polyphenols, phytic acid and other toxic or anti-nutritional substances in the tank passes through the screen Drain after filtering; add 12 tons of clear water again (add water for the third time), stir for 15 minutes, and let stand for 10 minutes; open the drain port at the bottom of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com