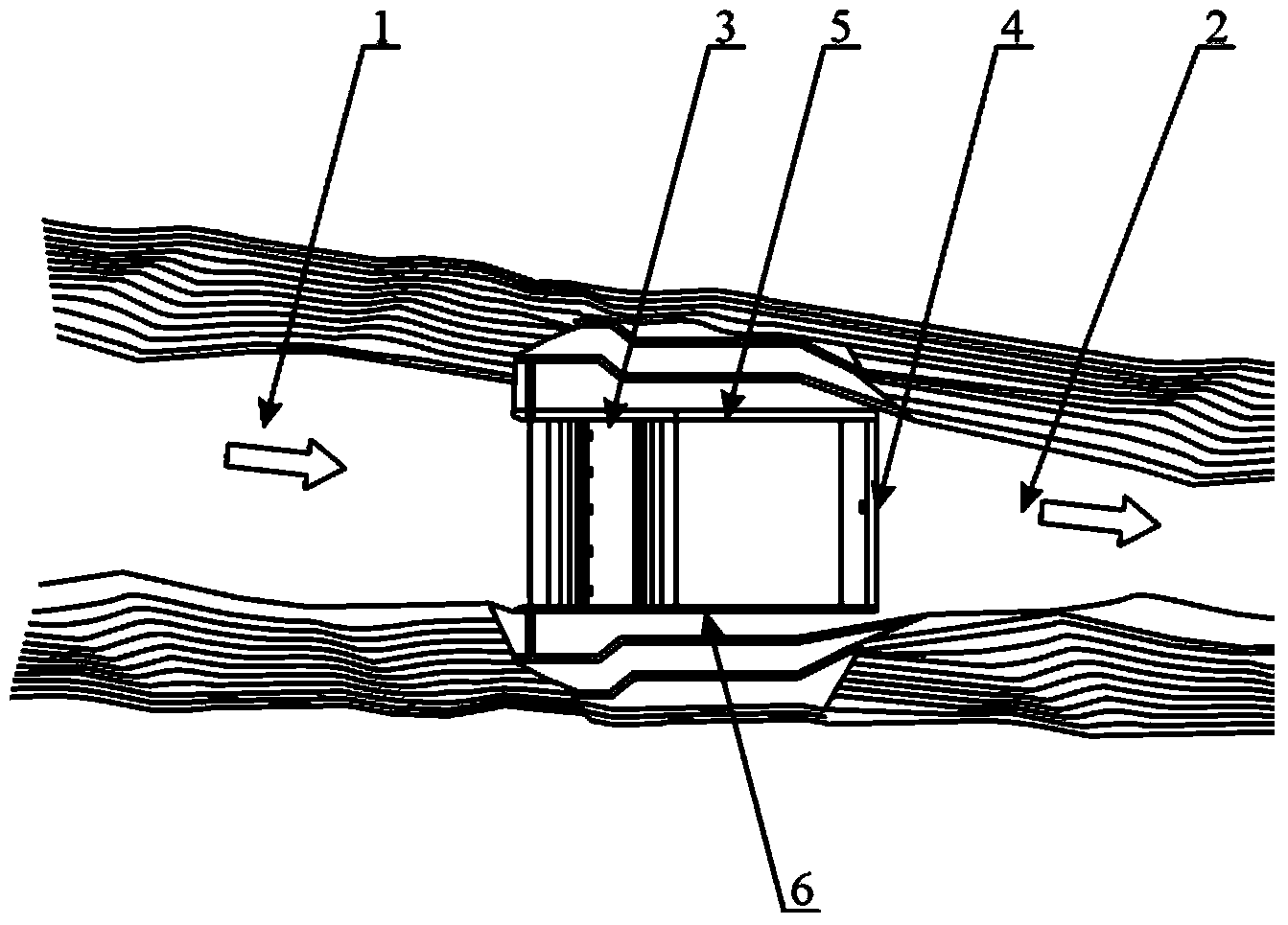

Stilling pool with laterally-effluent revolution and rolling energy dissipation function

A stilling pool and trough pool technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of large amount of excavation works and unsatisfactory energy dissipation effect, so as to reduce construction costs and reduce excavation works. The effect of reducing the amount of construction and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

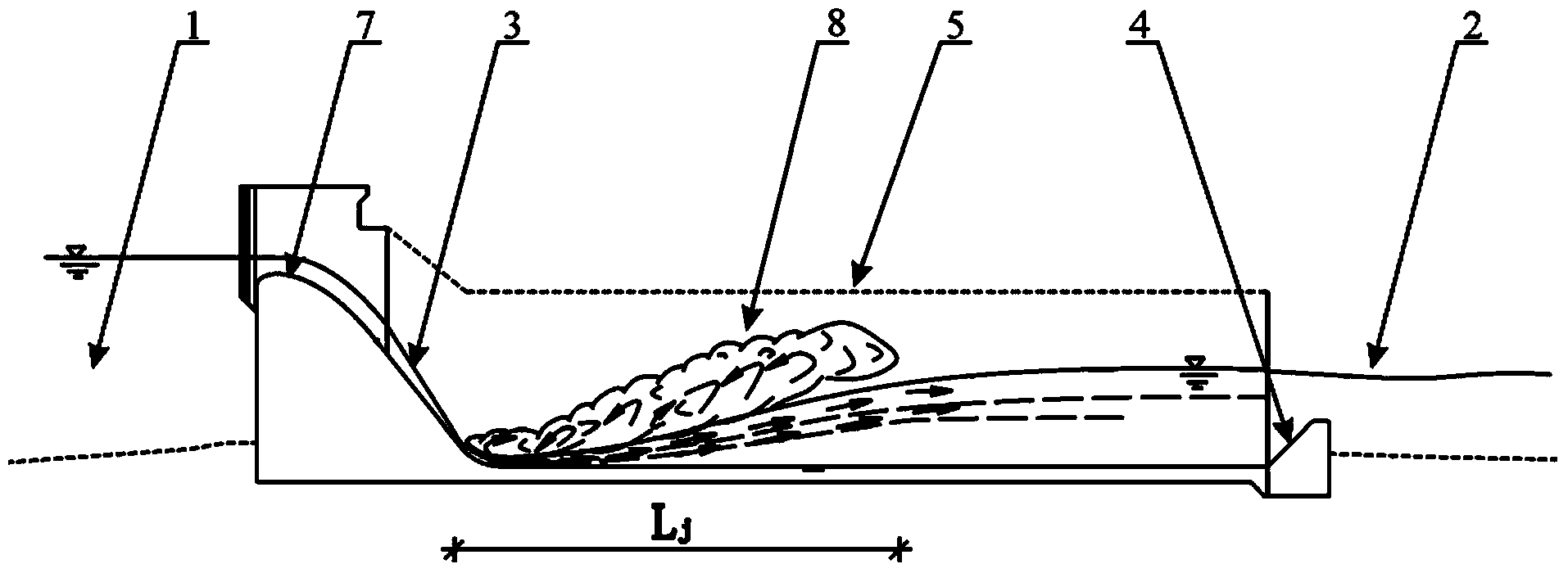

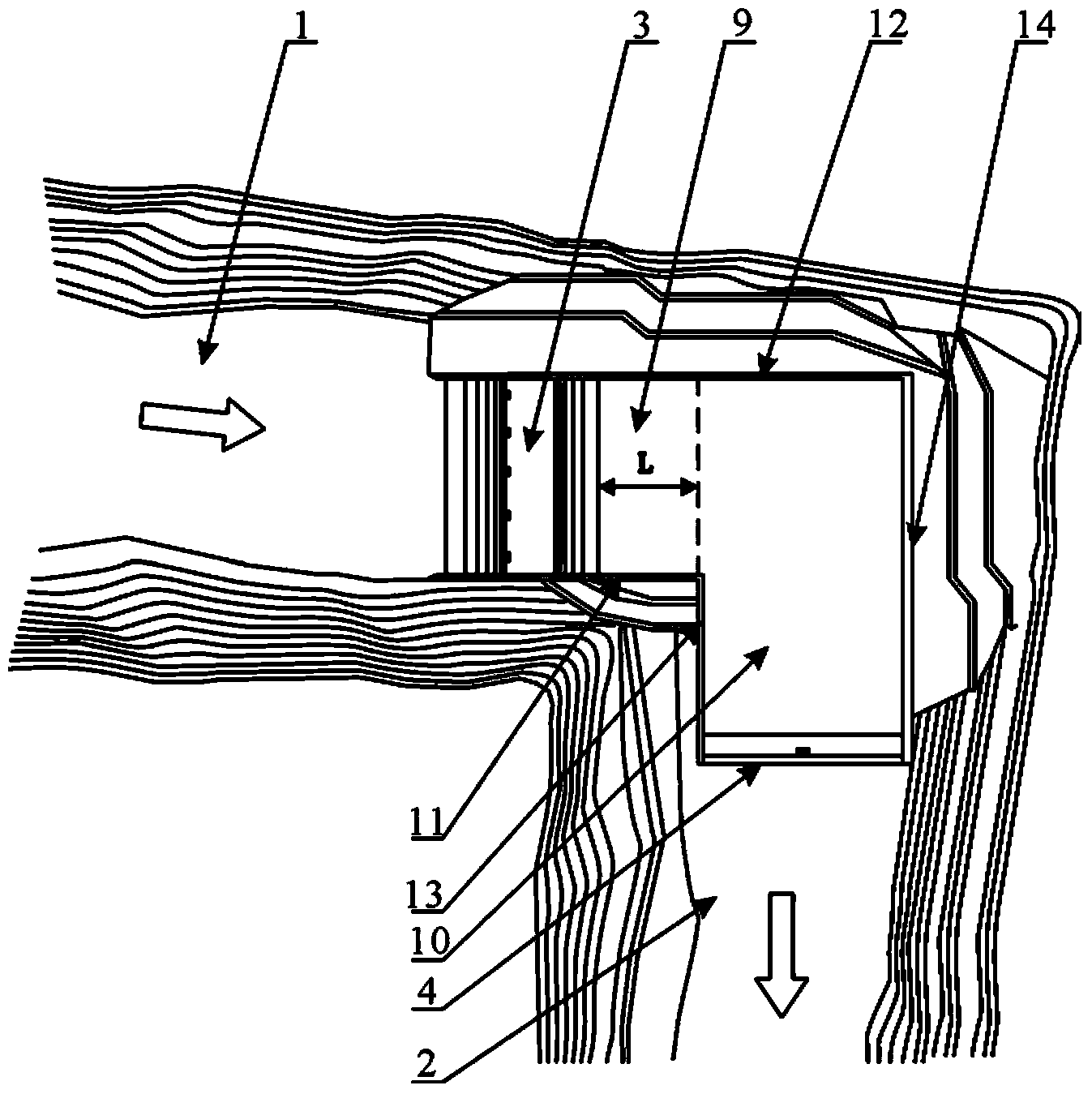

[0031] The stilling basin for the energy dissipation of the lateral outflow swirling rolling given in this embodiment, such as Figure 3A As shown, it is composed of a part of the tank 9 behind the overflow dam arranged in the upstream channel and a part of the tank 10 connected to the part of the tank and located in front of the water flow inlet of the downstream channel. The axes of the two parts of the tank intersect at 90°. The water flowing through the overflow dam 3 enters the stilling basin to generate a hydraulic jump 8, and then flows out of the stilling basin in a sideways rolling manner, so that the water flow can dissipate energy. A tail sill 4 is arranged at the tail of the tank pool 10 in front of the water inlet of the downstream channel. The inner side wall 11 and the outer side wall 12 of the part of the trough behind the overflow dam of the stilling pool, and the inner side wall 13 and the outer side wall 14 of the part of the trough in front of the water inl...

Embodiment 2

[0036] The structure of the stilling pool for the energy dissipation of the lateral outflow swirling roll given in this embodiment is as follows: Figure 3B As shown, it is basically the same as the stilling basin for lateral flow and rolling energy dissipation described in Embodiment 1, the difference is that the length of the inner side wall 11 of the part of the tank behind the overflow dam is the hydraulic jump of the stilling basin. 1.2 times the length, the tail of the trough in front of the water inlet of the downstream river is not provided with the tail sill 4, and the inner side wall 11, the outer side wall 12 of the trough behind the overflow dam of the stilling pool and the water flow inlet of the downstream river are not provided. The height of the inner side wall 13 and the outer side wall 14 of the part of the tank in the front is equal to 1.2 times of the design flood level height.

Embodiment 3

[0038] The structure of the stilling pool for the energy dissipation of the lateral outflow swirling roll given in this embodiment is as follows: Figure 3B As shown, it is basically the same as the stilling basin of the lateral flow and rolling energy dissipation described in Embodiment 1, the difference is that the length of the inner side wall 11 of the part of the tank behind the overflow dam is the hydraulic jump of the stilling basin. 1.2 times the length, the tail of the trough in front of the water inlet of the downstream river is not provided with the tail sill 4, and the inner side wall 11, the outer side wall 12 of the trough behind the overflow dam of the stilling pool and the water flow inlet of the downstream river are not provided. The inner side wall 13 and the outer side wall 14 of the front part of the trough are slope structure side walls inclined to the outside, and their height is equal to 1.1 times of the design flood level.

[0039] The schematic diagram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com