Linear-section type immature soil wall with built-in steel and wood mesh and manufacturing method thereof

A raw earth wall and grid technology, applied to walls, building components, buildings, etc., can solve problems such as low bearing capacity, poor integrity of raw earth walls, and weak seismic performance, and achieve the effect of improving integrity and solving waste problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiment:

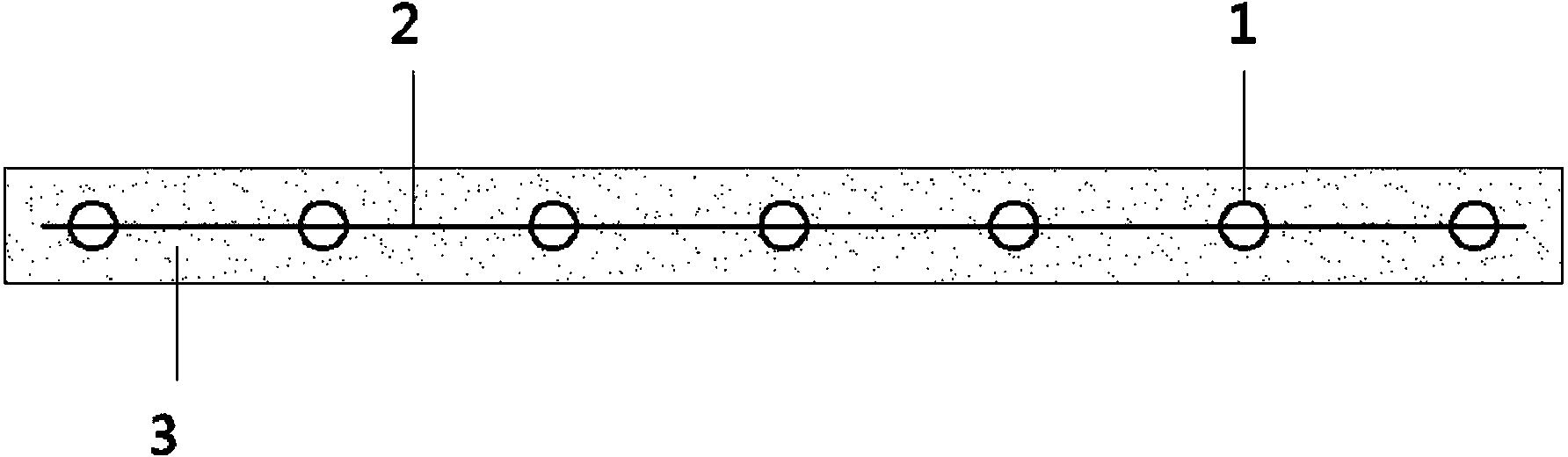

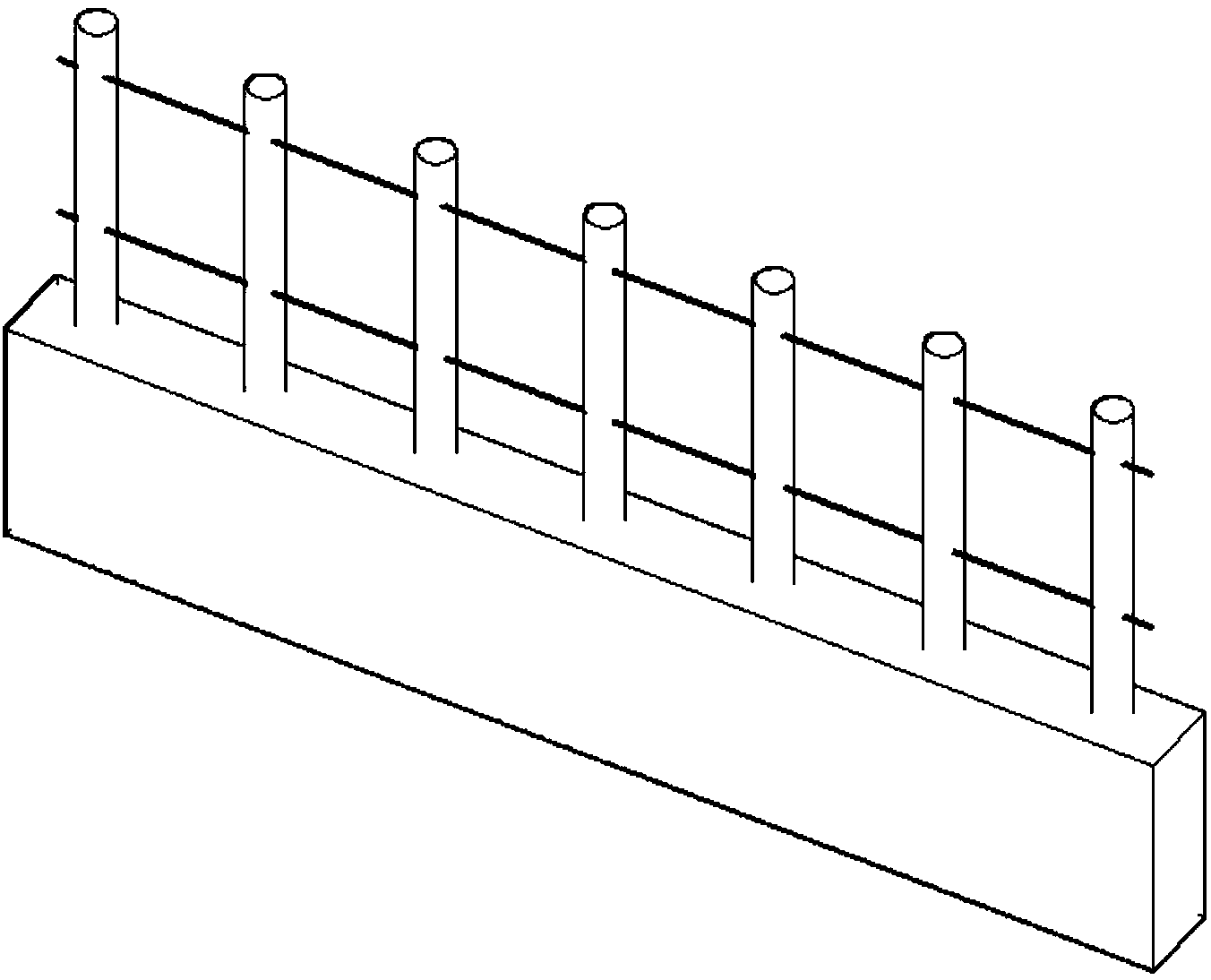

[0021] Such as Figure 1-3 As shown, a raw soil wall with a built-in steel-wood grid in a one-shaped section of the present invention is mainly composed of small-diameter timber 1, lead wire 2, and raw soil 3. It is characterized in that: there is a steel-wood grid composed of small-diameter wood and lead wire inside, the overall performance is greatly improved, and at the same time, the cost is low, the construction is simple and convenient, green and environmentally friendly, and it is suitable for low and multi-storey new building systems.

[0022] The above is a typical embodiment of the present invention, and the practice of the present invention is not limited thereto.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com