Ultrahigh building toilet wall stone installation structure

A technology for installing structures and toilets, applied in building construction, construction, covering/lining, etc., can solve the problems of increased material and labor costs, many process quality control points, and difficult construction period compression, to improve installation quality and installation efficiency. , Reduce the installation time, simplify the effect of the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Example: such as Image 6 Shown: a super-high building bathroom wall stone installation structure, which includes a fixing part 1, a waterproof adhesive strip 1, a waterproof adhesive strip 2 3, and a new type of composite board stone 4.

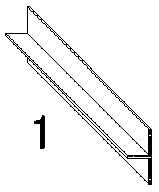

[0026] Such as figure 1 As shown, an insert is arranged laterally outside the fixing part 1 . The fixing part 1 is a "T" shaped steel part. Its structural strength has passed the load-bearing test, and its main features are strong structural rigidity and easy installation.

[0027] Such as figure 2 As shown, the section of the waterproof rubber strip-2 is circular.

[0028] Such as image 3 As shown, the section of the waterproof rubber strip 2 3 is circular. Waterproof strip 1 2 and waterproof strip 2 3 have passed the watertightness test to meet the waterproof requirements. Their characteristics are that they can effectively isolate the external space and prevent water from flowing to the base of the structure to cause stone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com