Hydraulic automatic climbing unloading platform

A unloading platform and hydraulic technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of large bearing capacity, low labor intensity, high safety, etc., and achieve the improvement of bearing capacity and climbing speed Fast, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation

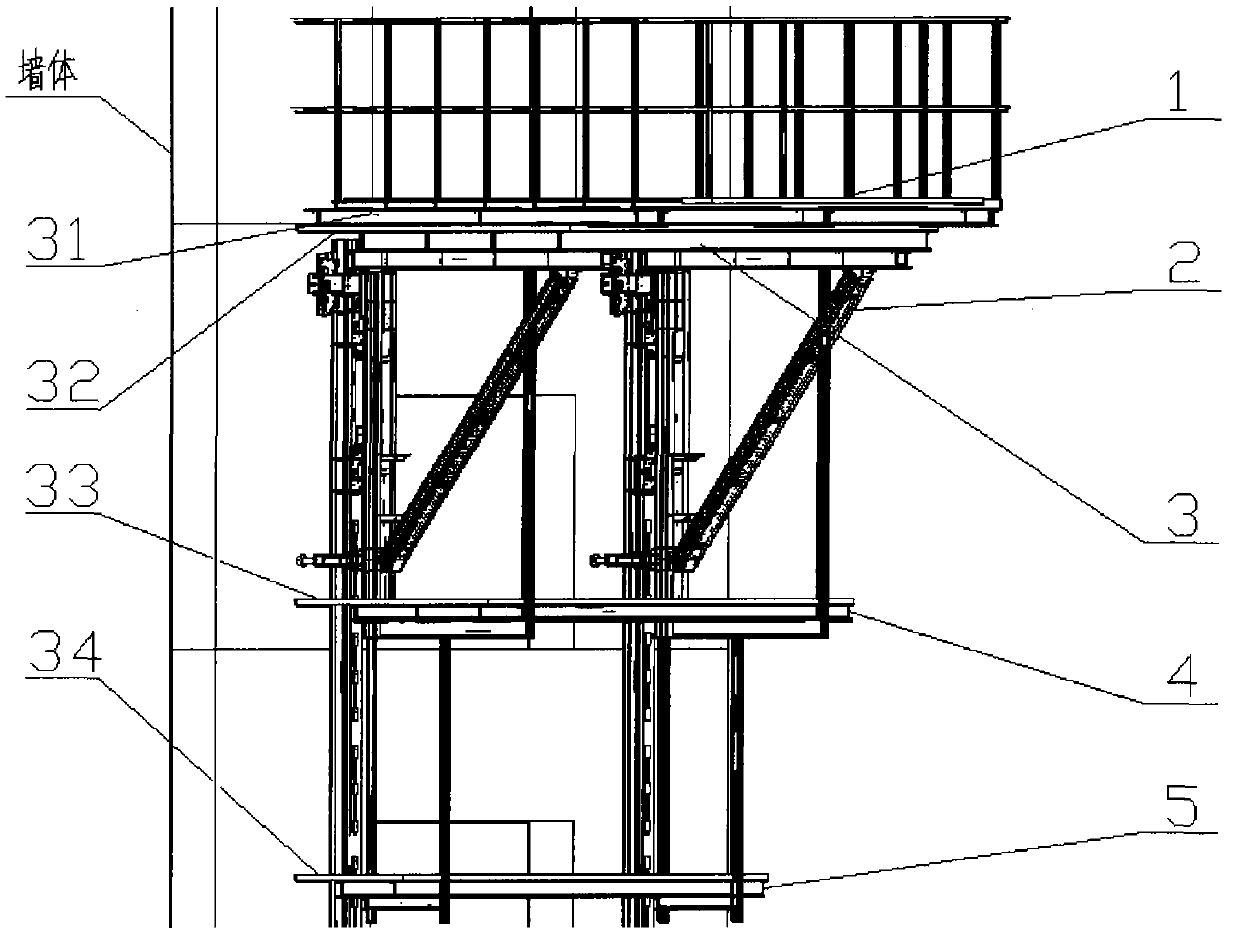

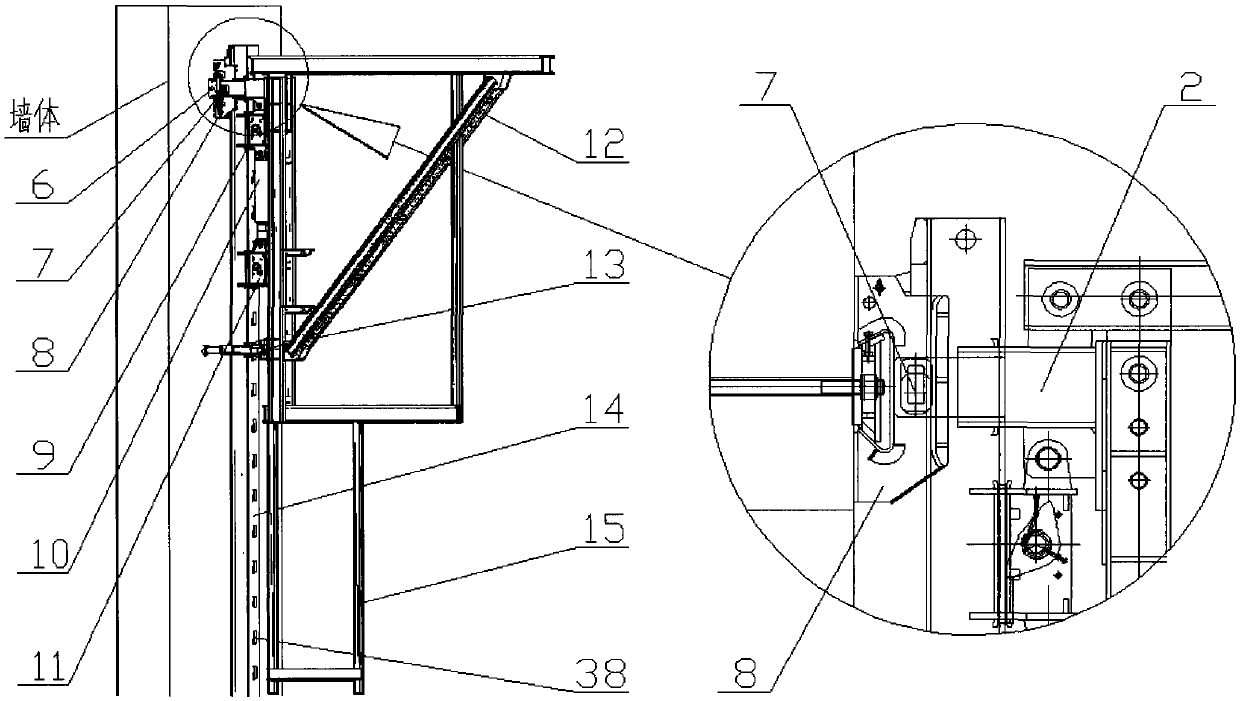

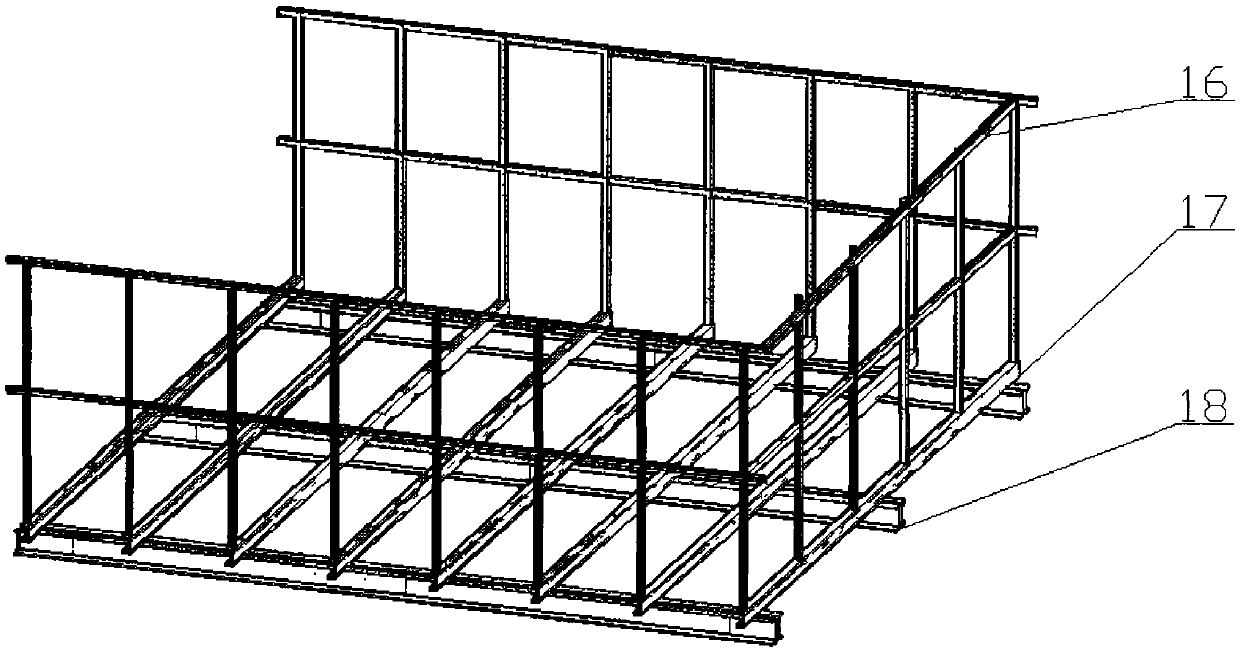

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention includes a stereotyped unloading platform (1), two sets of hydraulic climbing unloading platform machine positions (2), four main operating platform beams (3), three climbing operating platform beams (4), two maintenance Operation platform beam (5), a cover protection system (38) etc. are formed. Use the through-wall bolts (6) to install the attachment device (8) on the outer side of the wall. The machine position (2) of the hydraulic climbing unloading platform is fixed on the attachment device (8) through the anti-tilt plate (7). Adjust the top wall support leg (13) to fully contact the wall, and make the hydraulic climbing unloading platform machine position (2) perpendicular to the wall. Use platform beam U-bolts (35) to fix the two ends of the main operating platform beam (3) on the two main bearing frames (12) respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com