Manufacturing technique for light-weight wall plate

A production process and lightweight wallboard technology, applied in the direction of manufacturing tools, ceramic molding machines, mold separation devices, etc., can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

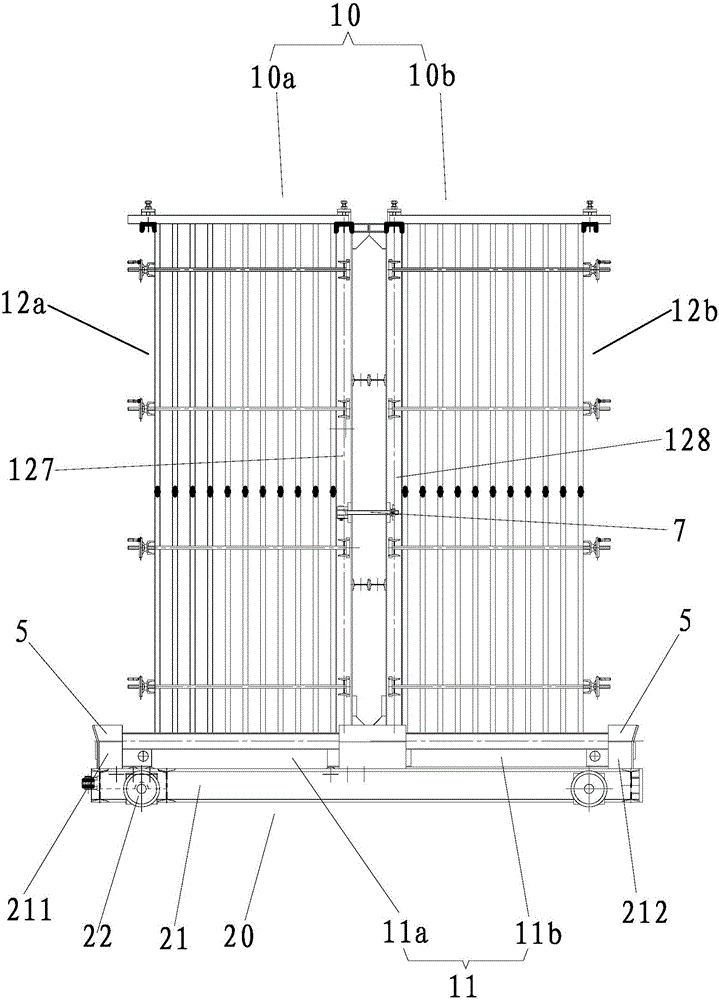

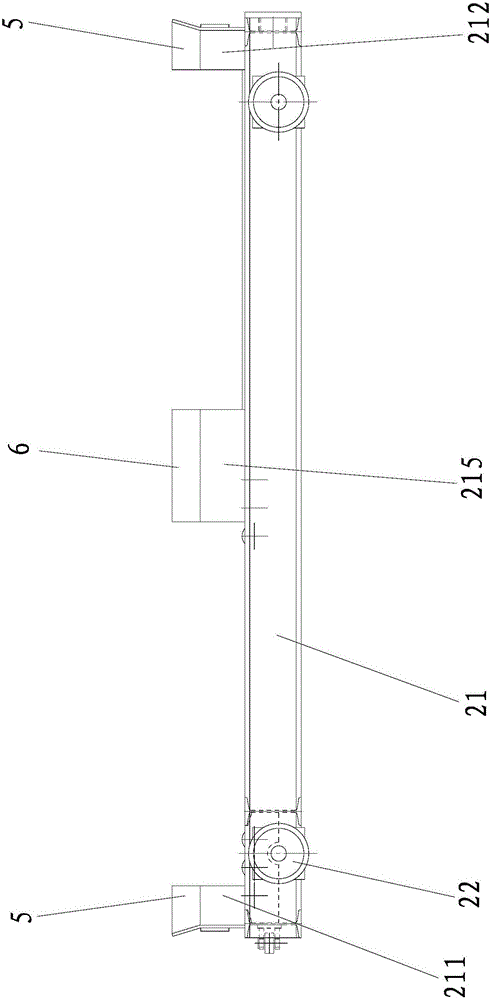

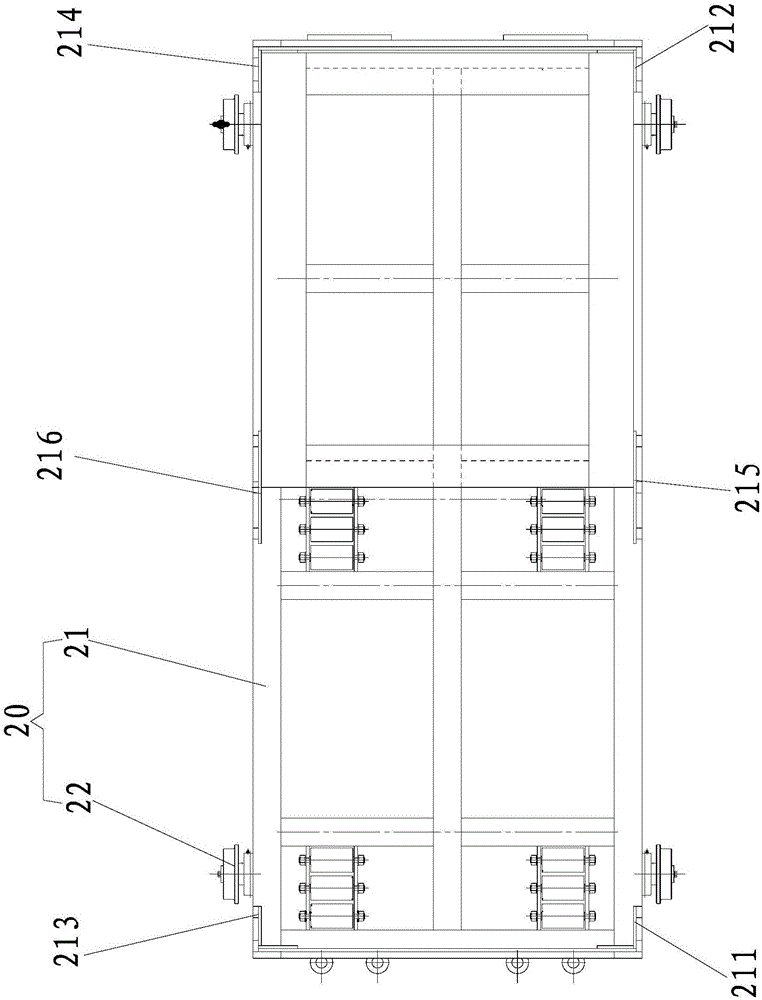

[0020] A vertical mold forming machine of a lightweight wallboard of the present invention, such as Figure 1-6 Shown, comprise forming mold frame 10 and walking trolley 20, and this walking trolley 20 comprises working platform 21 and is located at the walking wheel 22 of bottom surface four corners of working platform 21, and this forming mold frame 10 comprises bottom mold 11 and vertical formwork 12, The bottom mold 11 is placed on the working platform 21. The bottom mold 11 is a square mold frame. Partition plate 121, each middle partition plate 121 can surround a square frame, and each middle partition plate 121 is tightened together by several adjusting screw rods 3, makes each middle partition plate 121 form a square frame that can be taken and placed easily, The square mold frame is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com