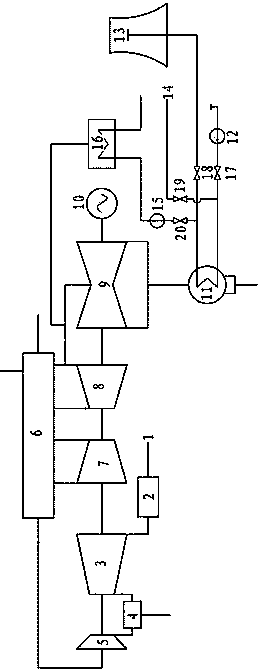

Waste heat utilization system of gas-steam combined cycle generator set

A technology of generating unit waste heat and combined cycle, which is applied in the direction of steam application, steam engine installation, combined combustion mitigation, etc., and can solve the problems of system thermal efficiency reduction, heat waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The accompanying drawing is a specific embodiment of the present invention. This embodiment includes the steam coming out of the gas-steam combined cycle generator set and entering the condenser 11. The water outlet pipe of the condenser 11 is connected in parallel with the circulating water pump 12, the cooling water tower 13, the heat network return pipe 14 and the water outlet pipe of the condenser 11. The first heat supply station 16 connected to the network circulating water pump 15, the first heat supply station 16 is connected to the steam turbine; the gas-steam combined cycle generator set is the compressor 3 connected to the air pipe 1 through the filter screen 2, and the compressor 3 passes through the combustion chamber. 4 is connected to the gas turbine 5, the flue gas pipeline of the gas turbine 5 is connected to the waste heat boiler 6, the steam pipeline of the waste heat boiler 6 is connected to the steam turbine, and the steam turbine includes a high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com