Dual-valve orifice-area-variable fuel nozzle

A fuel nozzle and nozzle hole area technology, which is used in fuel injection devices, engine components, machines/engines, etc., can solve the problem that fuel nozzles cannot achieve flexible and adjustable fuel injection rules, and achieve the effect of improving fuel atomization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

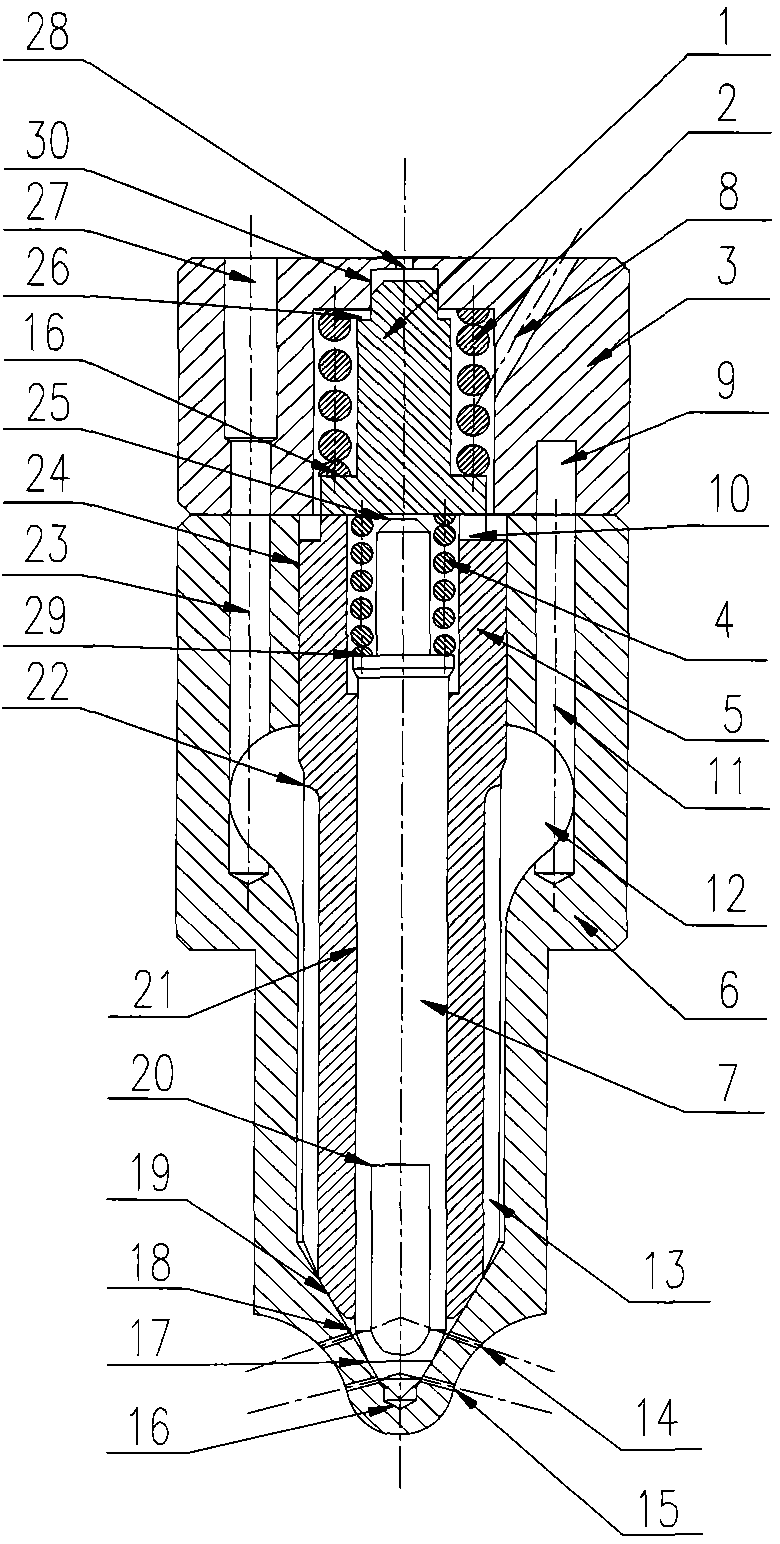

[0021] Preferably, the oil inlet ring groove 9 of the adapter seat 3 communicates with the oil inlet hole 27 of the adapter seat. The nozzle body 6 includes two oil inlet passages, the main oil inlet hole 23 and the auxiliary oil inlet hole 11. The main oil inlet hole 23 and the auxiliary oil inlet hole The oil holes 11 communicate with the oil tanks 12 respectively.

[0022] Preferably, the number of milling planes 20 is 2 to 4, and they are evenly arranged in the circumferential direction.

[0023] Preferably, the number of oil inlet grooves 13 is 2 to 4, and they are evenly arranged in the circumferential direction.

[0024] Preferably, the hydraulic diameter of the auxiliary nozzle hole 14 is smaller than 1 / 4 of the hydraulic diameter of the main nozzle hole 15 .

[0025] Preferably, the cone angle of the conical surface where the main injection hole 15 and the auxiliary injection hole 14 are located is in the range of 140°-160°, and the number of injection holes is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com