Medium and low temperature smoke online pre-ash-removal device of rotary hearth furnace

A low-temperature flue gas, rotary hearth furnace technology, applied in the field of metallurgy, can solve problems such as high cost, and achieve the effects of increasing the cross-sectional area of the airflow, prolonging the working time, and facilitating ash cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described now in conjunction with accompanying drawing.

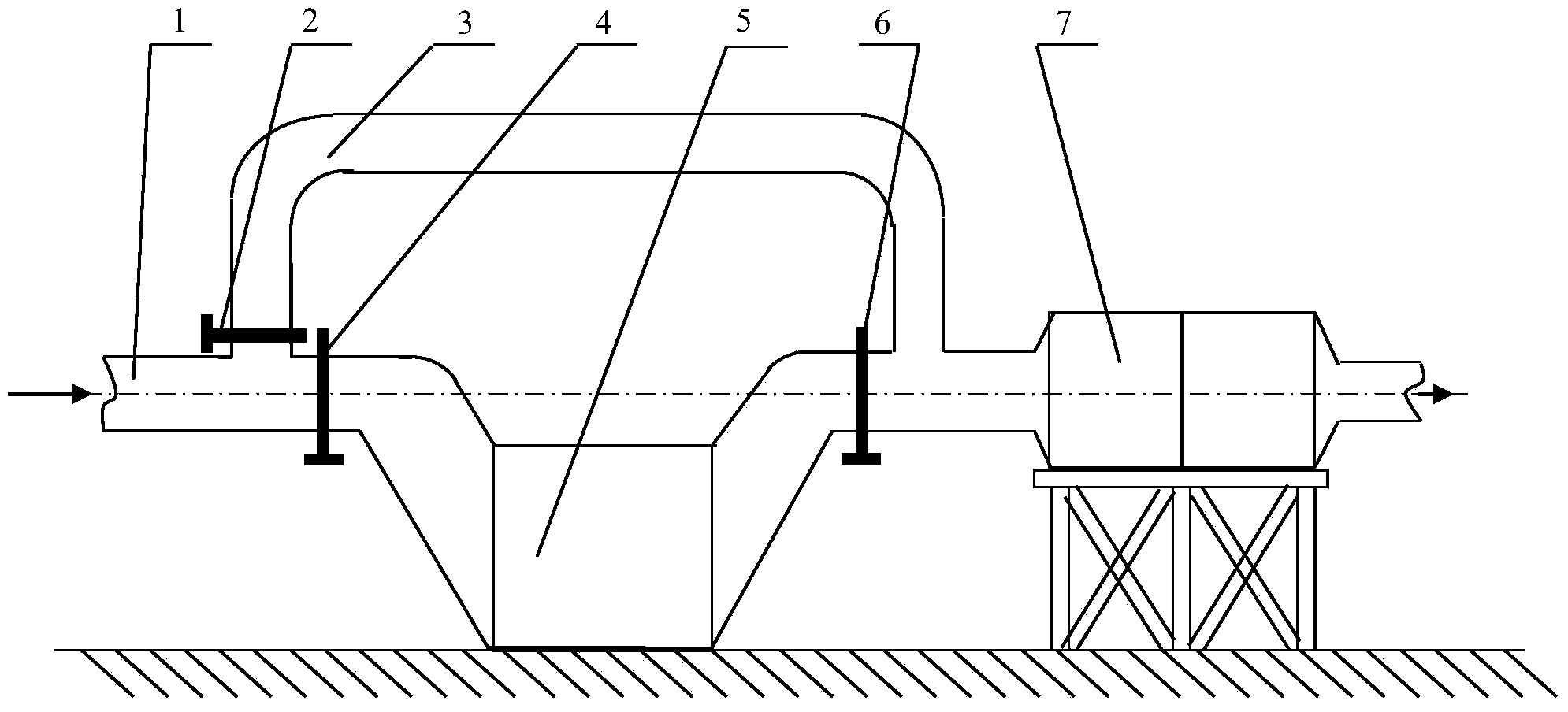

[0027] refer to figure 1 , the online pre-cleaning device of the present invention comprises a flue gas main pipeline 1, a dust fall chamber 5, a first valve 4, a second valve 6, a bypass pipeline 3, and a third valve 2; wherein, the flue gas main pipeline 1 The first end of the first end is connected with the external preheating boiler (the air inlet of the preheating boiler is connected with the gas outlet of the rotary hearth furnace, and the preheating boiler and the rotary hearth furnace are in the figure 1 are not shown in), the second end is connected to the air inlet of the heat exchanger 7; a first valve 4 is provided on the pipe near the first end of the flue gas main pipe 1, and the A second valve 6 is arranged on the pipe near the second end of the flue gas main pipeline 1; a dust fall chamber 5 is connected to the flue gas main pipeline 1 between the first valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com