Tubular furnace air-path structure of carbon sulfur analyzer

A technology of carbon and sulfur analyzer and tube furnace, which is applied in the preparation of test samples, etc., can solve the problem of residual gas in the gas chamber, and achieve the effect of convenient and quick connection and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

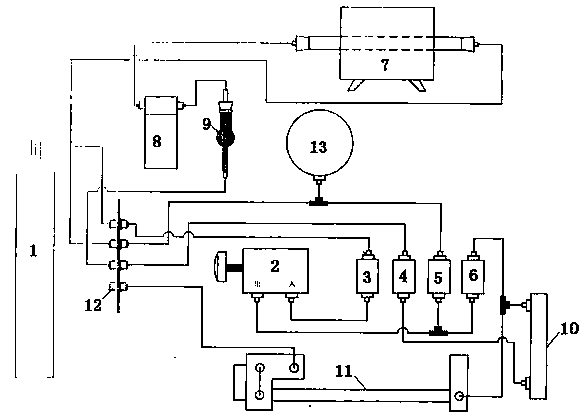

[0015] Such as figure 1 As shown, a tube furnace gas circuit structure of a carbon and sulfur analyzer includes an oxygen source 1, a gas chamber 11, a pneumatic constant value device 2, a flow meter 10, a dryer 9, a dust removal device 8, a tube furnace 7, an oxygen Control valve 3, intake control valve 5, outlet control valve 4, cleaning control valve 6 and exhaust port 12.

[0016] The oxygen source 1 communicates with the input end of the oxygen control valve 3, the output end of the oxygen control valve 3 communicates with the input end of the pneumatic constant value device 2, the output end of the pneumatic constant value device 2, the input end of the intake control valve 5 and the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com