Batch storage battery formation quality monitoring system and monitoring method

A monitoring system and battery technology, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of not adapting to the needs of large-scale long-term production, low product qualification rate, poor accuracy, etc., to improve work efficiency and production. Efficiency, improving economic efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

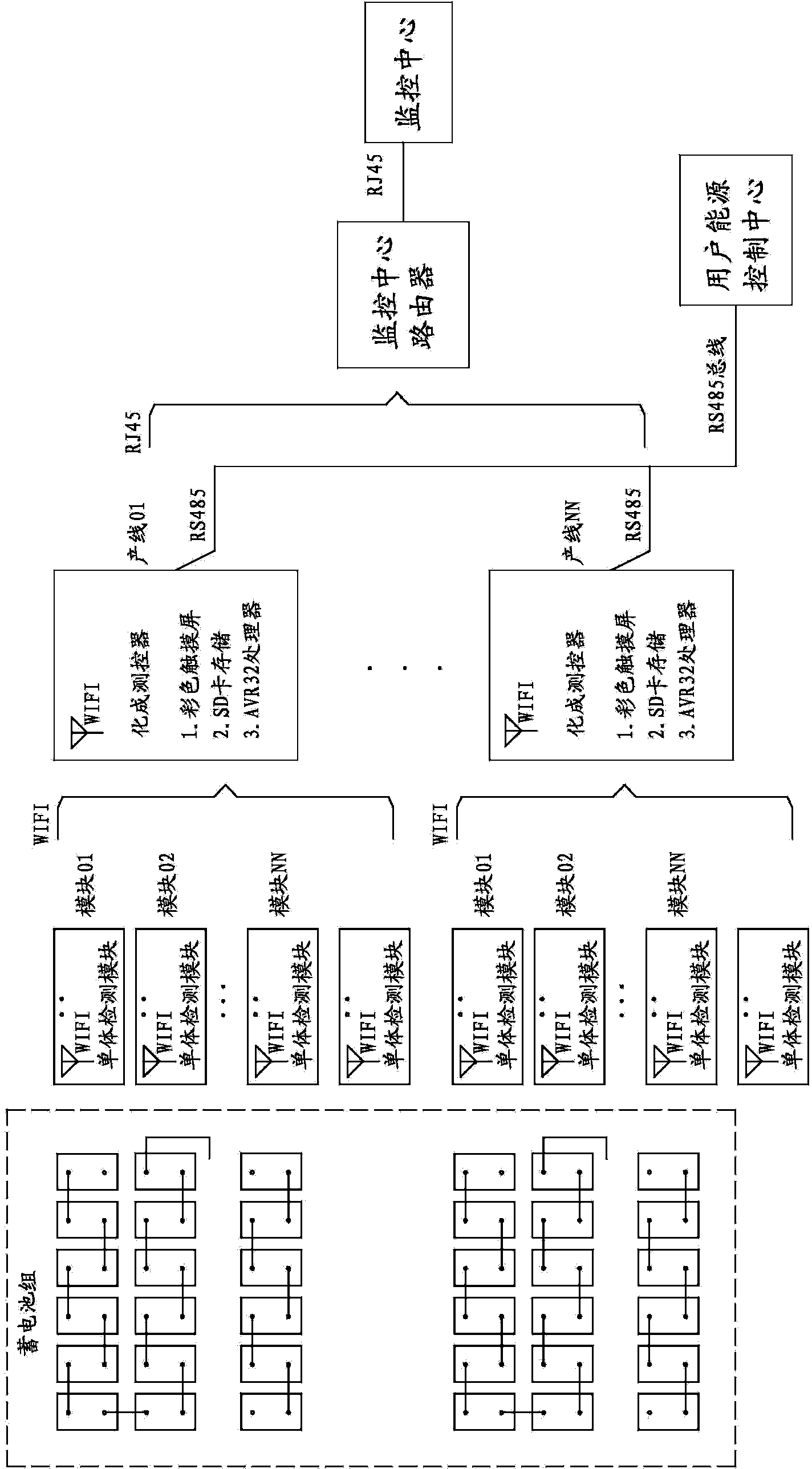

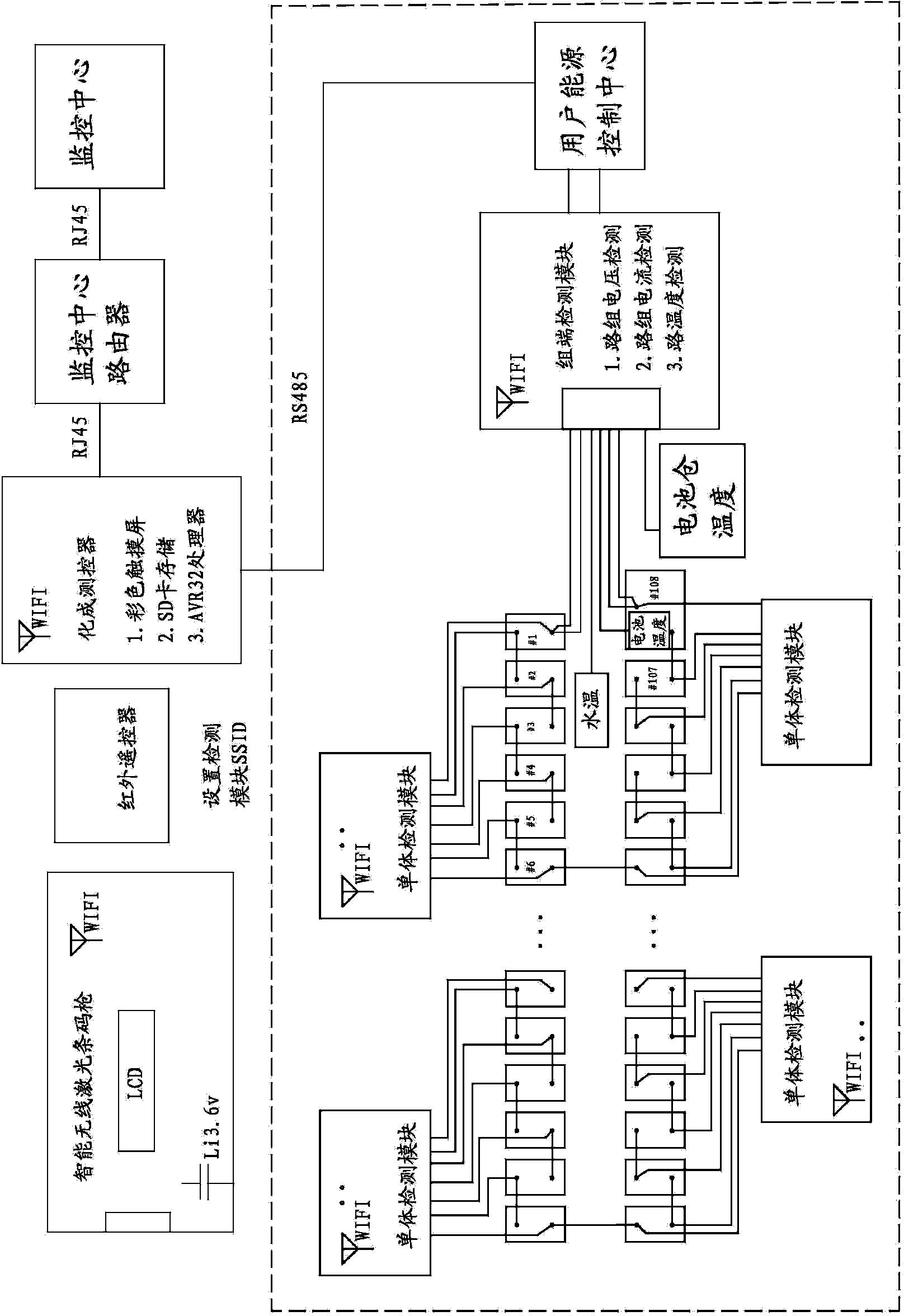

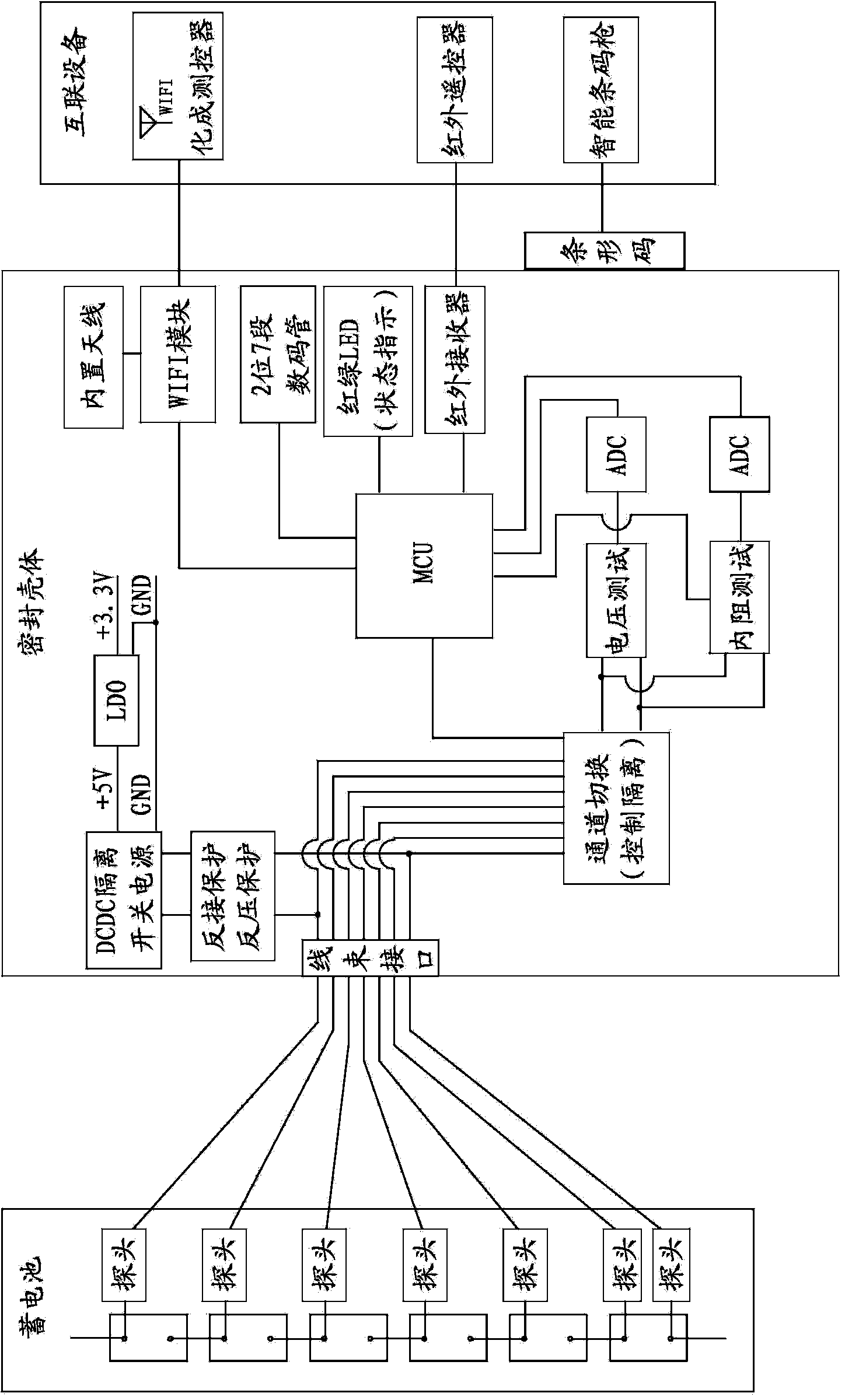

[0039] Such as Figure 1 to Figure 4As shown, the monitoring system for batch battery formation quality of the present invention includes at least one production line monitoring unit, an identity input module and a monitoring center; each production line monitoring unit includes a plurality of monomer monitoring modules, a group end monitoring module and a formation Measurement and control device; in the same production line monitoring unit, each of the monomer monitoring modules is connected to the positive pole or negative pole of each battery in a battery pack formed by a plurality of batteries connected in series; each of the monomer monitoring modules corresponds to It is better when connecting 6 batteries; the monomer monitoring module and the group end monitoring module are also connected to the formation controller, and all the batteries are connected to the group end monitoring module; each battery, each monomer monitoring module and each group The identification info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com