Apparatus For Design-based Manufacturing Optimization In Semiconductor Fab

An optimization, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, computing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention will be described in more detail below with reference to the drawings and reference numbers, so that those skilled in the art can implement them with reference to the description.

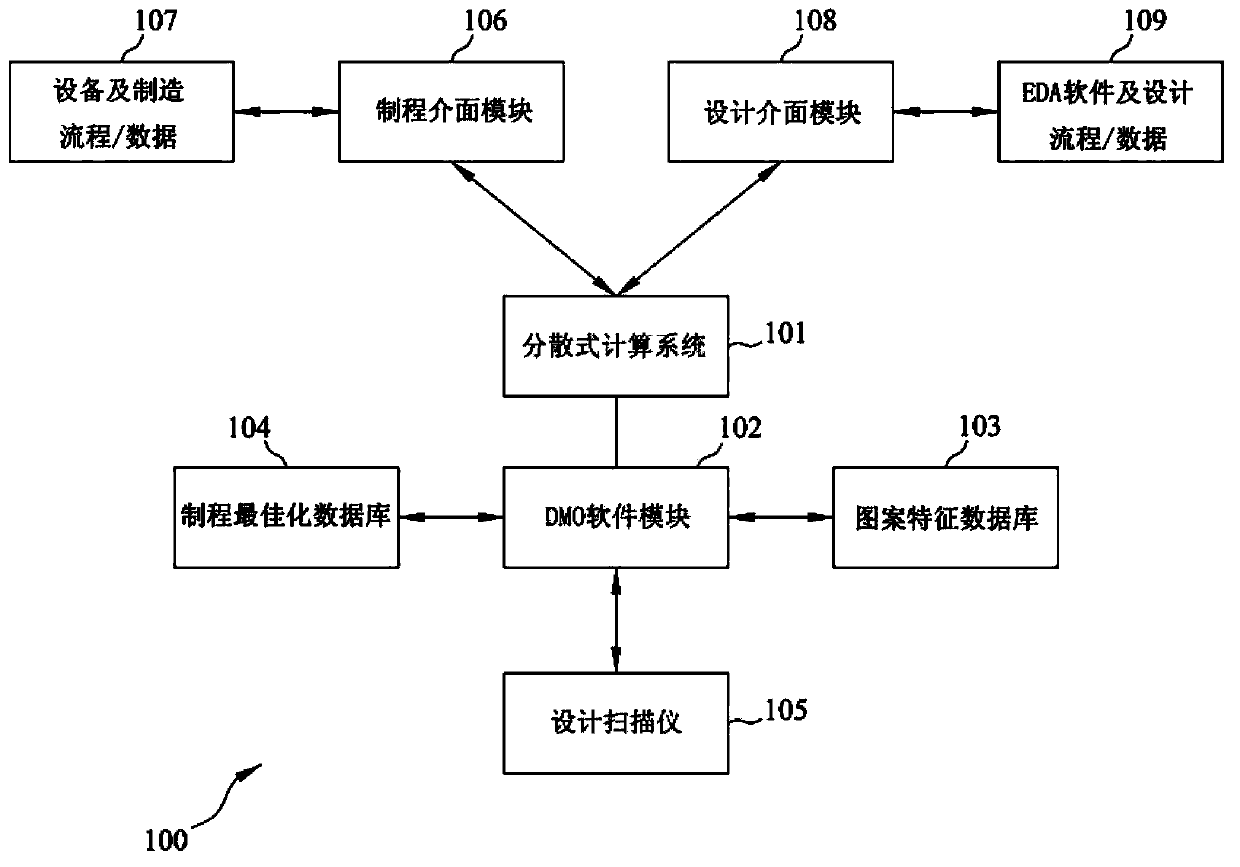

[0046] figure 1 It is a block diagram showing a design-based manufacturing optimization (DMO) apparatus 100 according to the present invention. The DMO device 100 includes a distributed computing system 101 and a DMO software module 102 , and further includes a pattern feature database 103 , a process optimization database 104 and a design scanner 105 . The distributed computing system 101 communicates with an EDA software and a design process 109 through a design interface module 108 , and communicates with equipment and a manufacturing process 107 through a manufacturing interface module 106 .

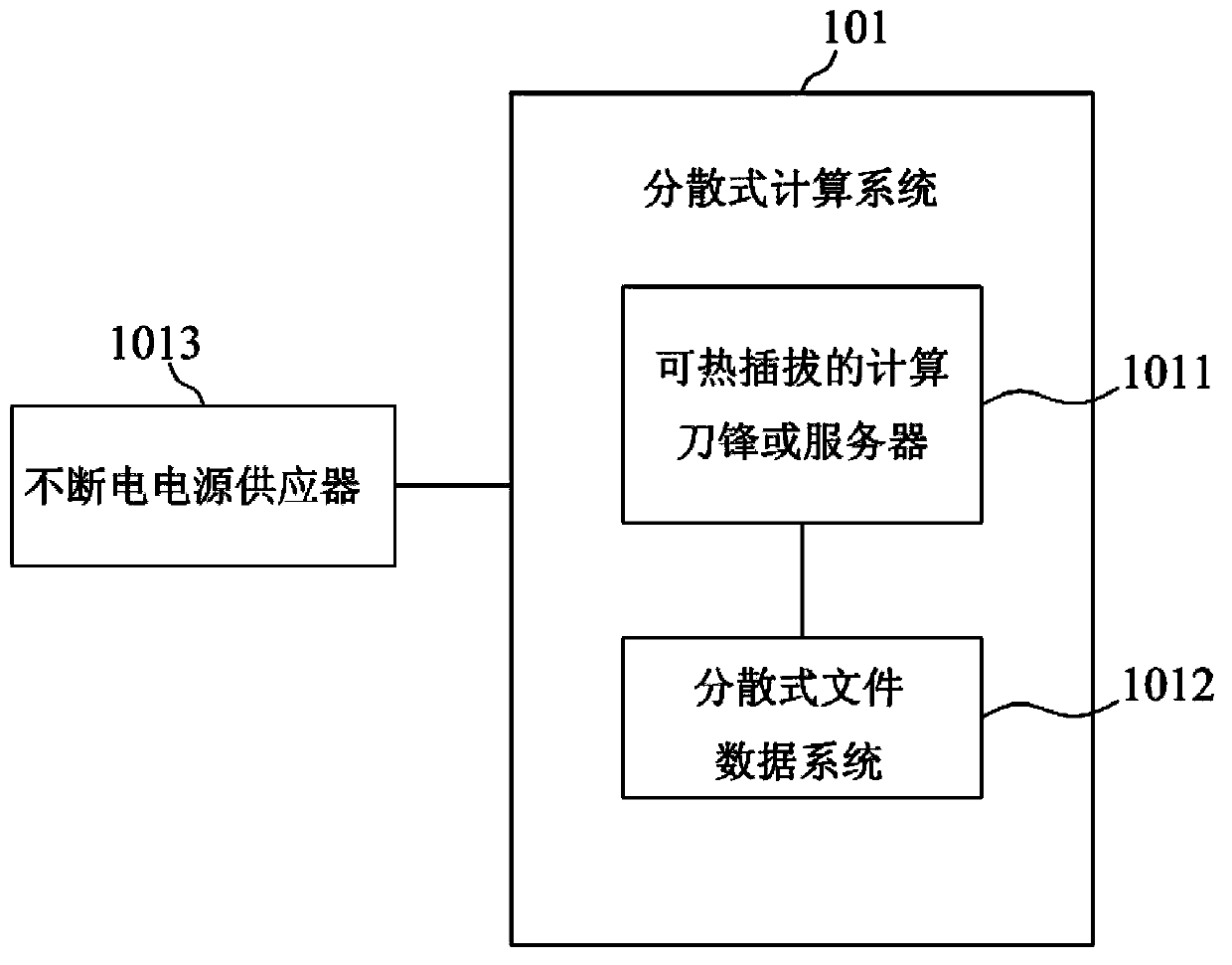

[0047] Such as figure 2 As shown, distributed computing system 101 is a fault-tolerant distributed computing system, which includes multiple redundant an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com