A Resistor for Condensing High-power Automobiles with New Lead Structure

A lead-out structure and high-power technology, applied in the direction of resistors, adjustable resistors, other resistor networks, etc., can solve problems such as the separation of the root of the wire harness from the insulation layer, the exposure of metal wires, and the reduction of insulation, so as to improve reliability. Effects of safety, guarantee of airtightness, and improvement of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

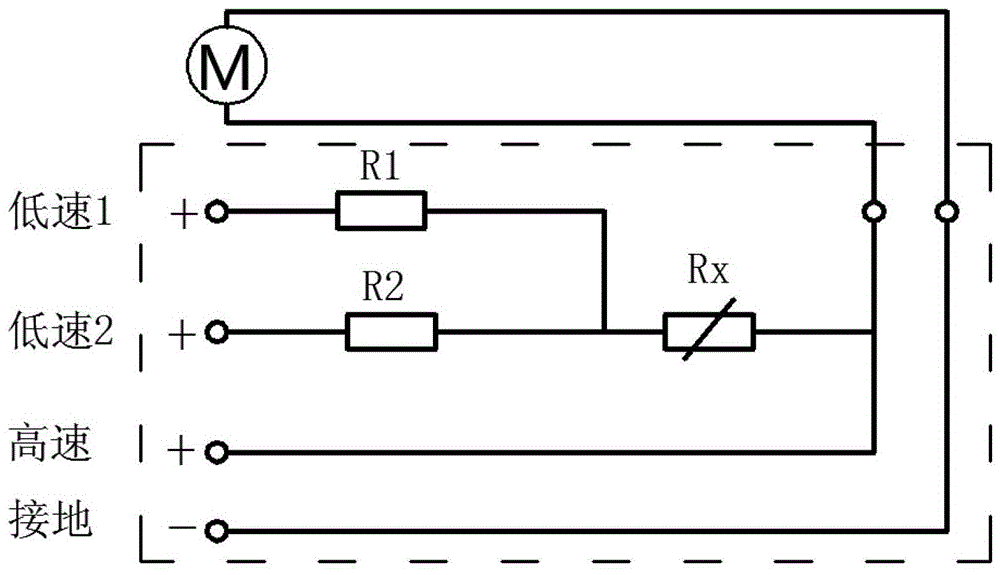

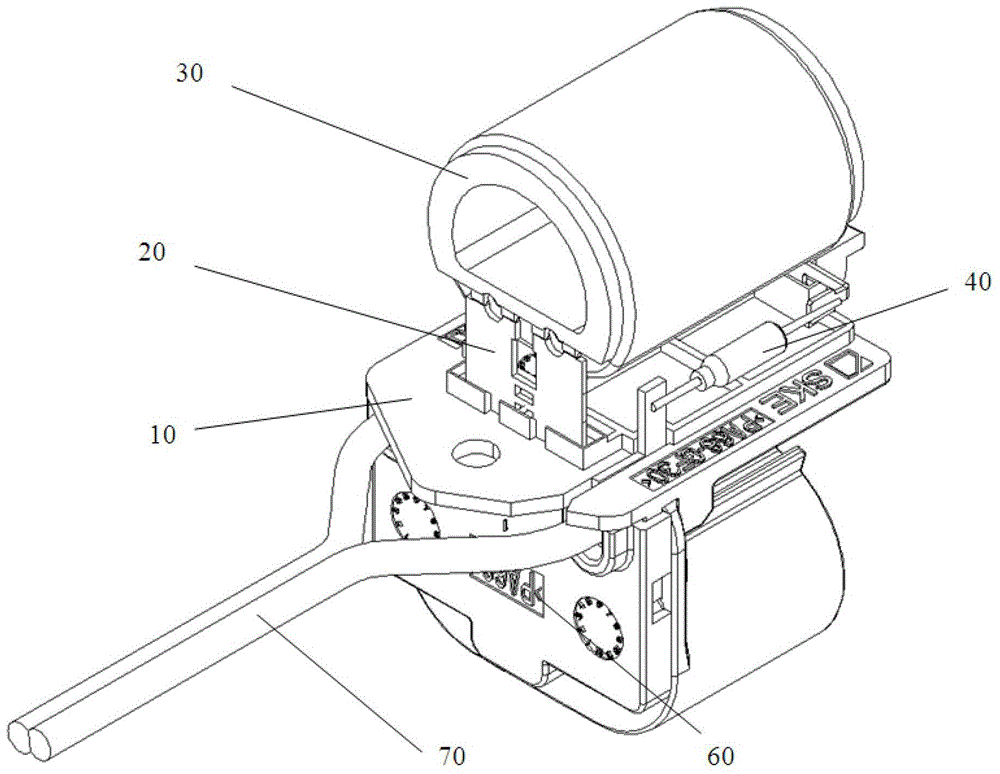

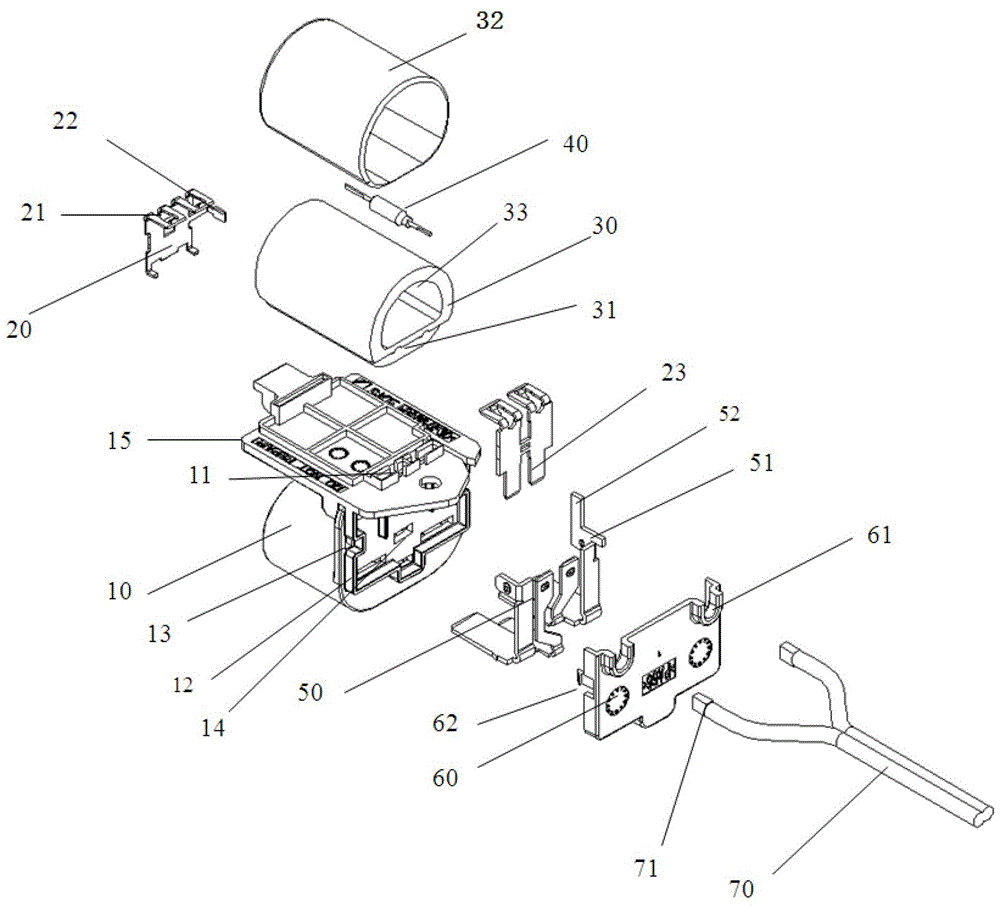

[0023] Such as Figure 2-3 As shown, a high-power automotive condensing resistor with a new structure includes a base 10, a connecting bracket 20, a resistance assembly 30, a temperature fuse 40, pins 50, a rear cover 60 and a wiring harness 70, and the connecting bracket 20 and the rear cover 60 are installed on the base 10, the resistance assembly 30 is fixed on the connection bracket 20, one end of the thermal fuse 40 is connected to the connection bracket 20, and the other end is connected to the pin 50, and the connection bracket 20 is connected to the pin 50 , and the wire harness 70 is connected to the pin 50 after passing through the rear cover 60 .

[0024] The base 10 includes a base plate 15 and a connector housing located at the bottom of the base plate 15, the base plate 15 is provided with a plurality of bracket slots 11; the rear side of the connector housing is provided with a pin mounting area 12. The pin mounting area 12 is provided with a plurality of pin s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com