Locking method for preventing motor from being switched into short-circuit fault

A technology for short-circuit faults and electric motors, applied in circuit devices, emergency protection circuit devices, electrical components, etc., can solve the problems of expanding accidents, low voltage of power supply system, frequent starting, etc., and achieve the effect of preventing accidents from expanding and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

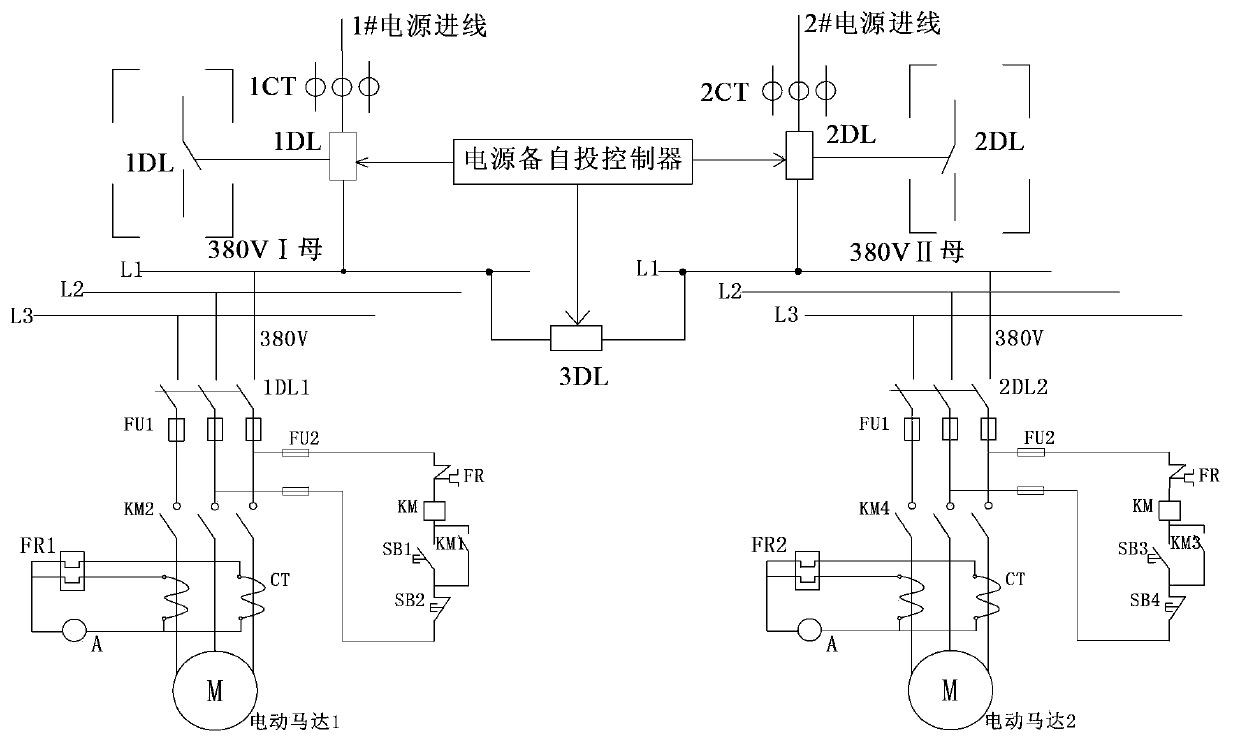

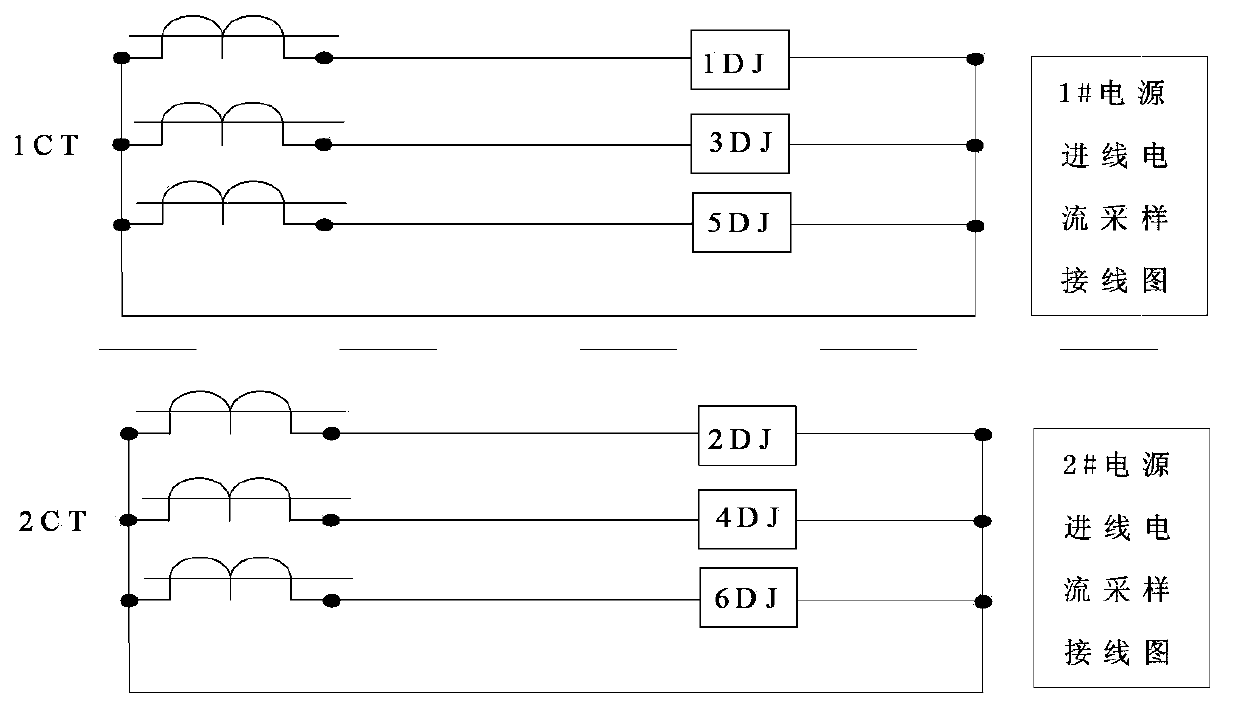

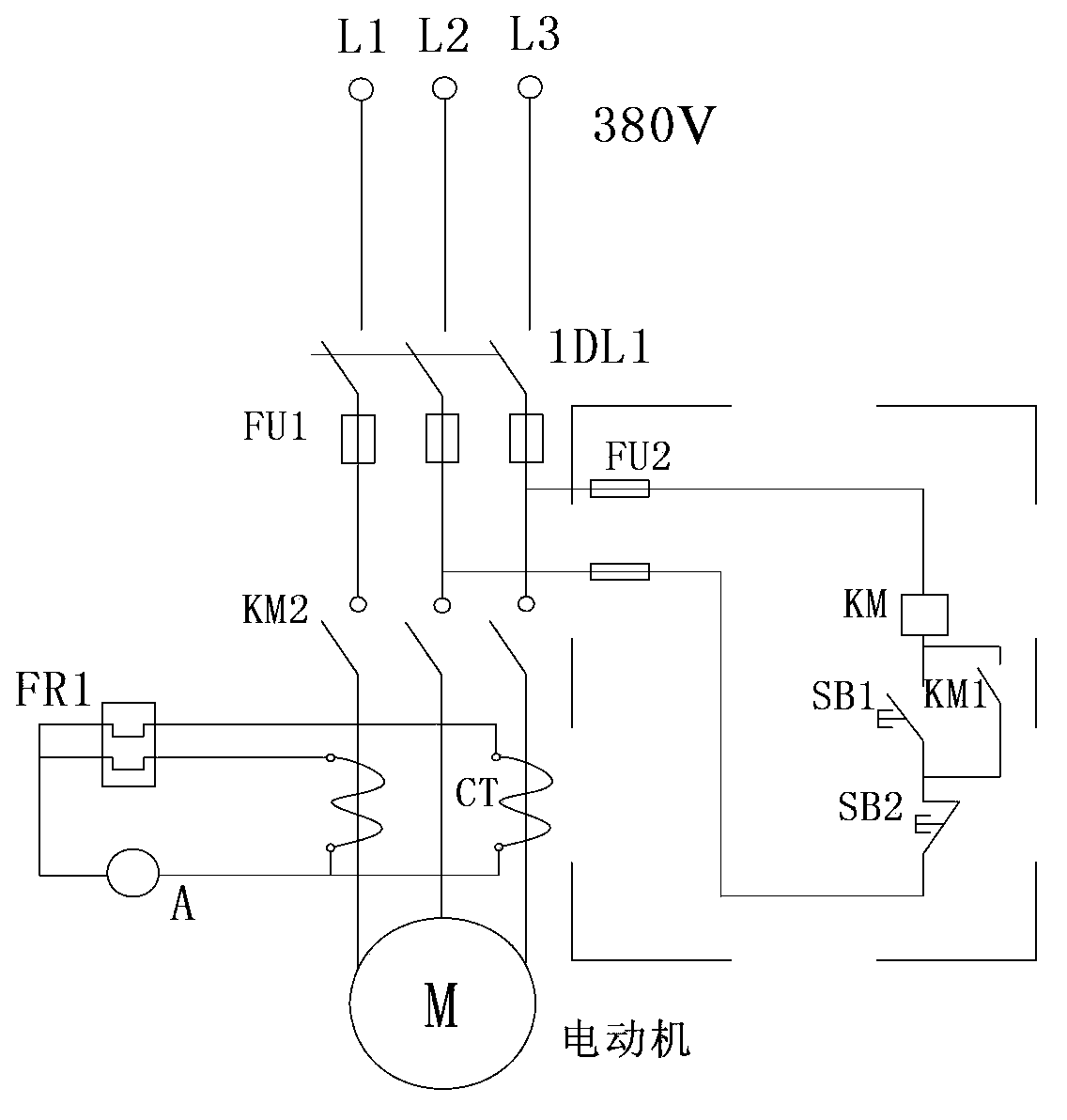

[0034] figure 1 Among them, the main circuit power supply of the motor is drawn from a certain section of the busbar in the substation, and the substation adopts a double-circuit incoming power supply and a single busbar segmented operation mode to supply external power, and the described double-circuit incoming power supply includes the first and second roads Incoming power supply, the first and second incoming power supplies are respectively connected to the corresponding first and second bus sections through the first and second incoming switches, between the first and second bus sections There is a contact switch between them, and the contact switch is controlled by the "preparation self-switching" device; when the first or second incoming power supply has a "power failure" fault, the "preparation self-switching" device jumps off the The incoming line switch corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com