Ultrasonic power source for transducer cascading

A transducer and ultrasonic technology, applied in the direction of impedance matching network, multi-terminal pair network, etc., can solve problems such as power supply capacity limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection of the present invention are not limited thereto.

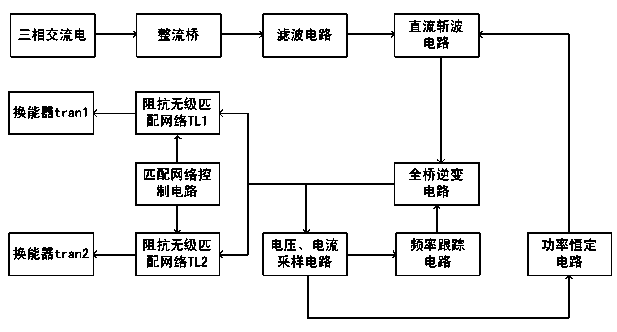

[0023] Such as figure 1 As shown, an ultrasonic power supply for transducer cascading, including a rectifier bridge, a filter circuit, a DC chopper circuit, a full-bridge inverter circuit, a first impedance stepless matching network TL1, a second impedance stepless matching network TL2, first transducer tran1, second transducer tran2, matching network control circuit, voltage and current sampling circuit, frequency tracking circuit, power constant circuit.

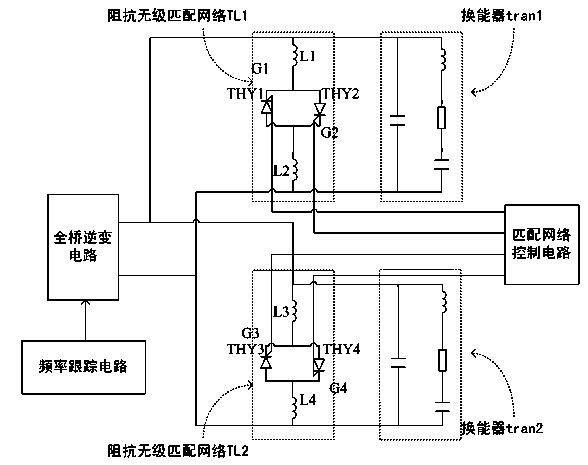

[0024] The connection diagram of the cascaded transducer is shown in figure 2 As shown, the first impedance stepless matching network TL1 is composed of a first thyristor THY1, a second thyristor THY2, a first inductor L1, and a second inductor L2. The second stepless impedance matching network TL2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com