A Stepless Impedance Matching Network for Ultrasonic Power Supply

A matching network, ultrasonic technology, applied in impedance matching network, multi-terminal pair network, etc., can solve problems such as limitations, and achieve the effect of simple control and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation, but the implementation and protection of the present invention are not limited thereto.

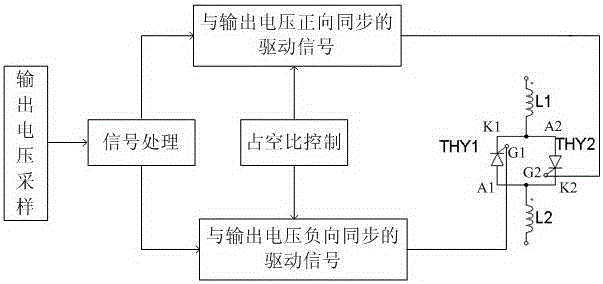

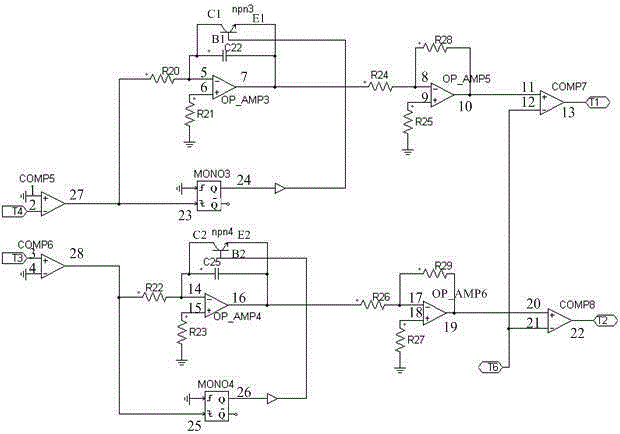

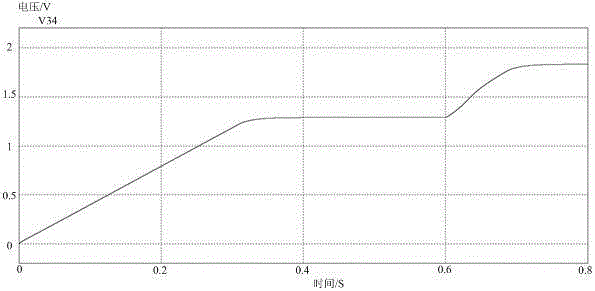

[0019] The matching network disclosed by the present invention is as figure 1 As shown, the matching inductance can be adjusted steplessly. By adjusting the size of the inductance, when the resonant frequency of the transducer drifts, the output voltage and current of the power supply can be in the same phase without changing the output frequency of the power supply. figure 2 is the circuit diagram of the signal processing module and the duty ratio control module in the matching network, such as figure 2 As shown, the output voltage of the inverter bridge of the ultrasonic power supply passes through the step-down high-frequency transformer to obtain the output voltage sampling signal, respectively passes through the first comparator COMP5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com