Double-insert feeding control structure of mosaic wheel

A technology of feeding control and chip insertion, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of waste of abrasive belt material, influence of chip insertion efficiency, and inability to obtain the performance of the effect, and achieve the effect of precise and reasonable transmission structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

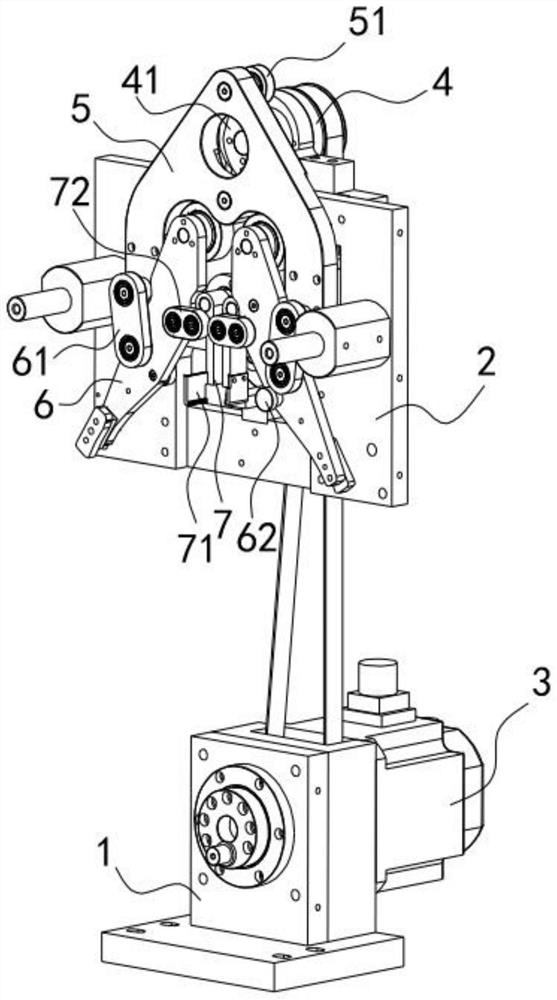

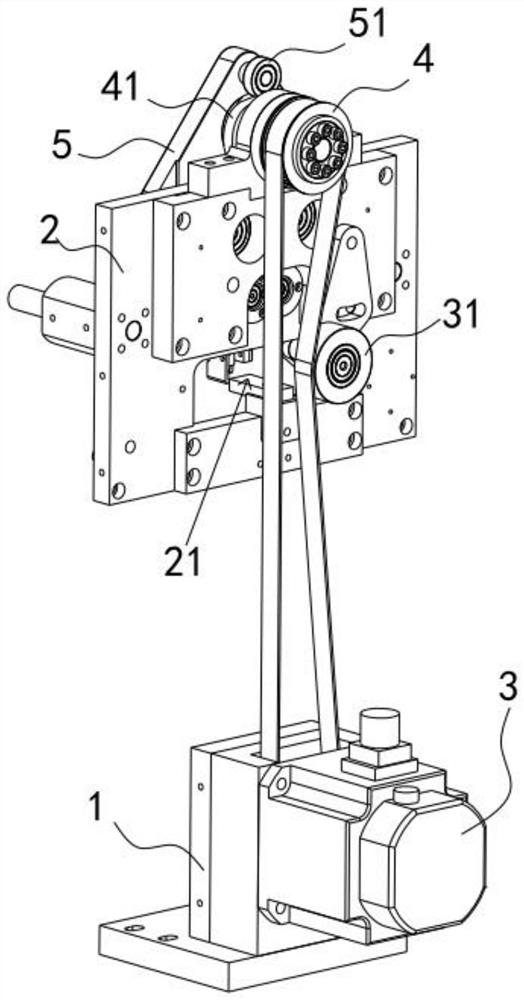

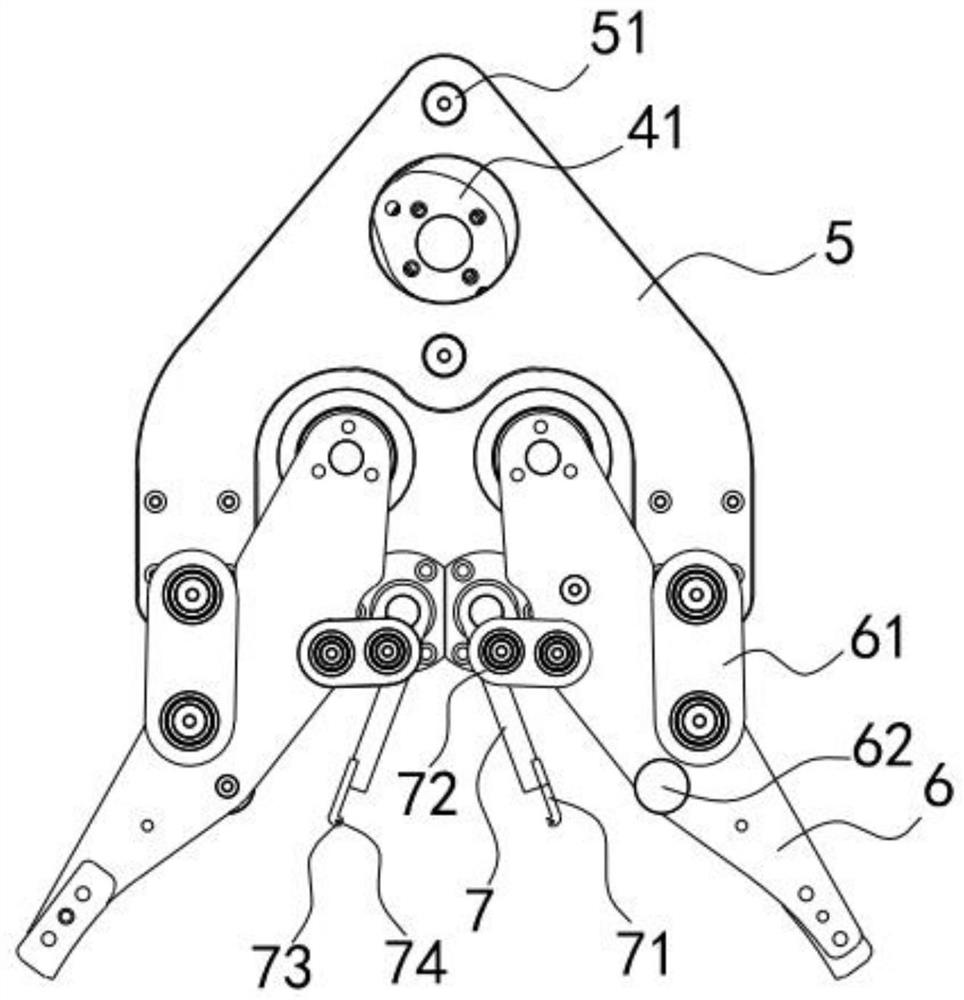

[0028] Such as Figures 1 to 3 As shown, the flower impeller double insert feeding control structure includes a base 1 and a drive base plate 2, a drive motor 3 is fixedly installed on the base 1, a drive shaft 4 is fixedly installed on the drive base plate 2, and the drive shaft 4 and the drive motor 3 transmission connection; also includes drive cam 41, drive cam 41 is coaxially connected with drive shaft 4; also includes movable plate 5, movable plate 5 top is provided with transmission wheel 51, and transmission wheel 51 contacts with drive cam 41, and transmission wheel 51 drives the movable plate 5 to move up and down with the rotation of the drive cam 41; it also includes the main transmission rod 6, one end of the main transmission rod 6 is hinged with the drive substrate 2, and the middle part of the main transmission rod 6 is driven and matched with the movable plate 5 through the hinged main transmission block 61 , the two ends of the main transmission block 61 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com