Cold storage

A technology for refrigerators and air conditioners, which is used in household refrigeration devices, lighting and heating equipment, defrosting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

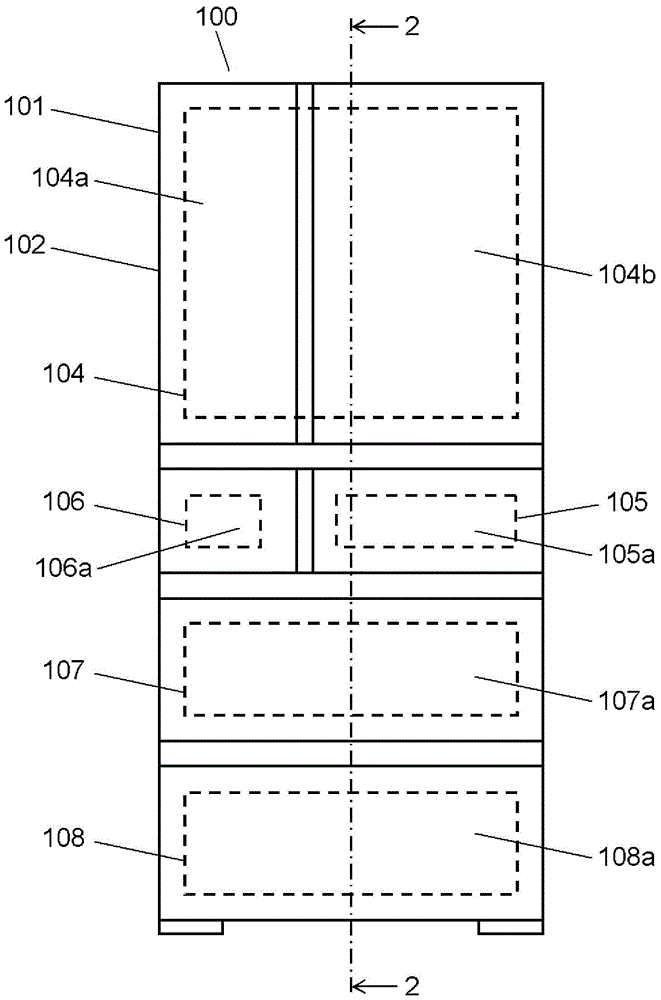

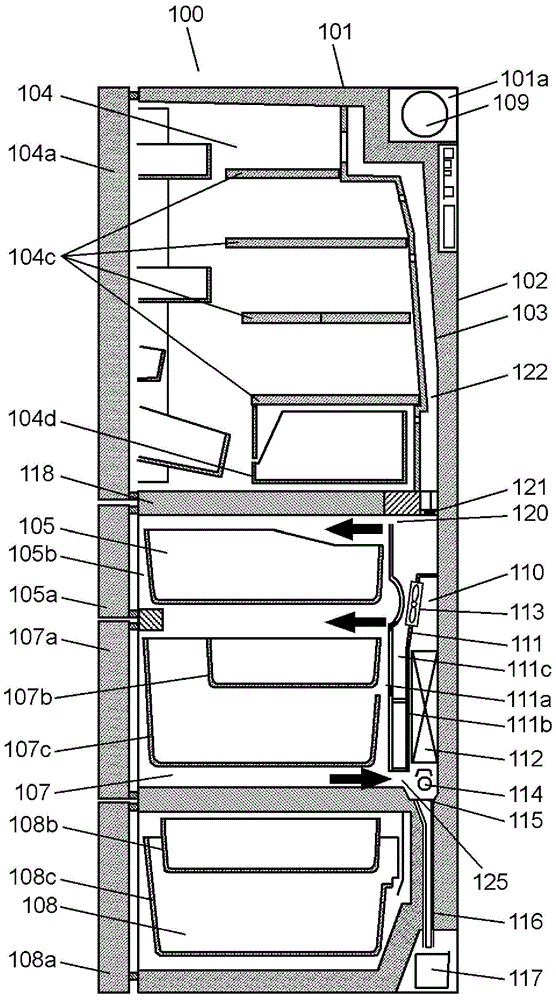

[0027] figure 1 It is a front view of the refrigerator of 1st Embodiment of this invention. figure 2 yes figure 1 2-2 sectional view of . image 3 It is an enlarged cross-sectional view of main parts of the refrigerator according to the first embodiment of the present invention.

[0028] exist figure 1 , figure 2 Among them, the heat insulation box 101 which is the main body of the refrigerator of the refrigerator 100 has the outer box 102 which mainly uses a steel plate, and the inner box 103 molded by resin, such as ABS. The space between the outer box 102 and the inner box 103 of the heat-insulating box 101 is foamed and filled with foaming heat-insulating materials such as rigid foamed polyurethane to insulate the surroundings. And the heat insulation box 101 is divided into some storage rooms.

[0029] A refrigerating room 104 serving as a first storage room, a second freezing room 105 serving as a fourth storing room, and an ice making room 106 serving as a fi...

no. 2 approach

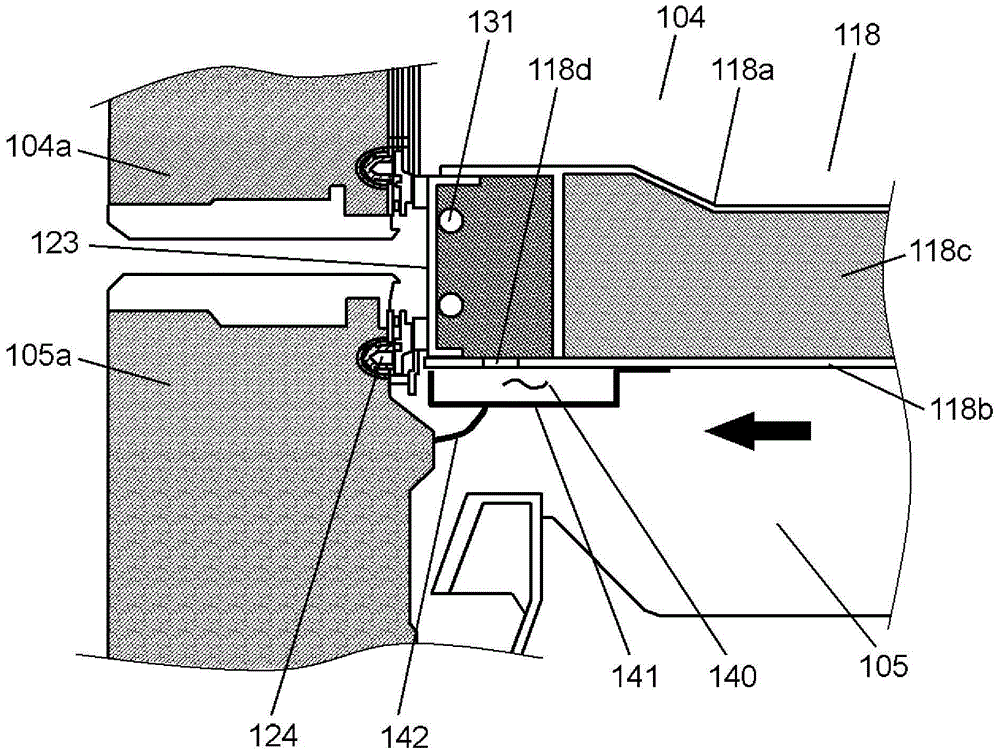

[0058] Figure 4 It is an enlarged view of a main part of the refrigerator according to the second embodiment of the present invention.

[0059] exist Figure 4 Among them, the end portion of the inner surface of the second freezer door 105a is provided with a door gasket 124 over the entire circumference. The door gasket 124 is in close contact with the metal receiving member 123 on the front surface of the partition wall 118 , the outer periphery of which is made of a resin part to separate the refrigerator compartment 104 from the second freezer compartment 105 , so as to prevent cold air from leaking to the outside. . Moreover, also in the refrigerator compartment 104, the 2nd freezer compartment 105, the ice maker compartment 106, the 1st freezer compartment 107, and the vegetable compartment 108, it has the structure which prevents cold air from leaking to the outside similarly.

[0060] In addition, in order to prevent dew condensation on the side surface of the stor...

no. 3 approach

[0074] Figure 5 It is an enlarged detailed view of a main part of the refrigerator according to the third embodiment of the present invention. Figure 6 It is a detailed view of a sealing member according to a third embodiment of the present invention. Figure 7 It is an enlarged detailed view of main components when the door of the refrigerator of the third embodiment of the present invention is closed.

[0075] exist Figure 5 , Figure 7 Among them, in order to prevent dew condensation on the side surface of the storage room, a heat radiation pipe 131 is arranged on the metal receiving member 123 . The metal receiving member 123 is heated by the heat of the radiation pipe 131 . The partition wall 118 is configured by fitting the upper partition plate 118a and the lower partition plate 118b up and down, respectively. Moreover, the partition wall 118 has the structure which sandwiched the heat insulation member 118c between the upper partition board 118a and the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com