Liquid inoculation machine for shiitake

The technology of mushroom stick and inoculation machine is applied in the field of machinery, which can solve the problems of difficulty in inoculation, cumbersome use, uneven inoculation, etc., and achieve the effects of realizing standardized production, reducing production cost and reducing labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

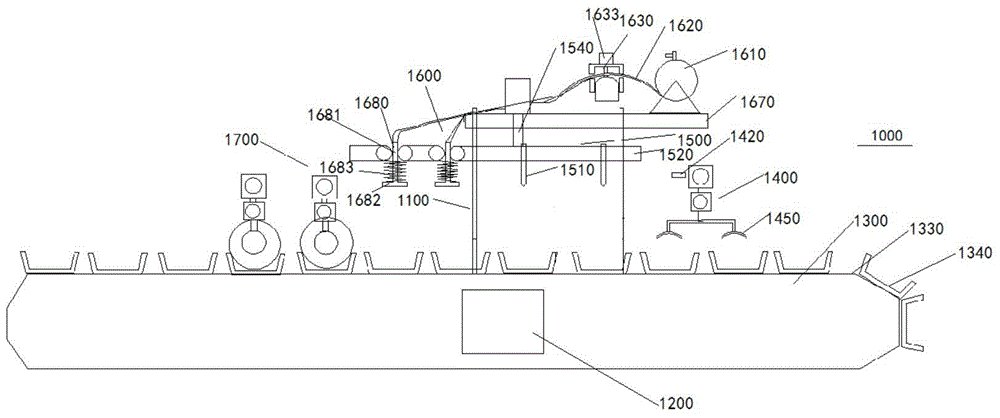

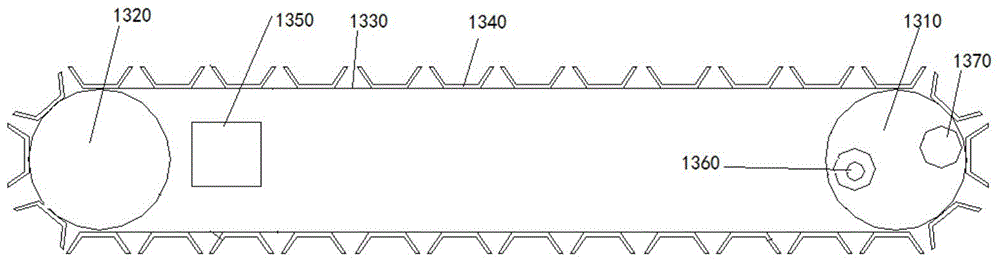

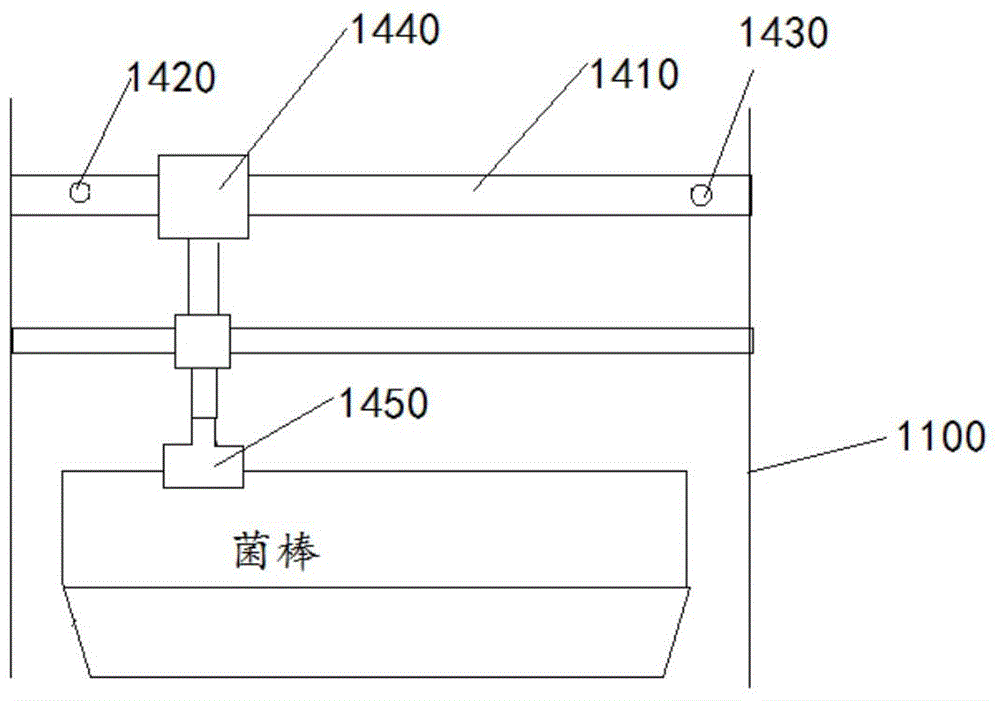

[0108] according to figure 1 It can be seen that according to the mushroom stick liquid inoculation machine 1000 of the present invention, comprising: frame 1100; Host control machine 1200, the host control machine 1200 is installed on the frame 1100, for receiving information and sending orders to control the liquid inoculation machine Operation; positioning displacement conveying device 1300, positioning displacement conveying device 1300 is installed on the bottom of frame 1100 and is connected with host controller 1200, in order to precisely control the mobile position of mushroom stick; disinfection device 1400, disinfection device 1400 is installed on frame 1100 The upper part is located above the positioning displacement conveying device 1300, and is used to sterilize the mushroom sticks on the positioning displacement conveying device 1300; the punching device 1500, the punching device 1500 is installed on the frame 1100, and is positioned above the positioning displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com