Gas-liquid mass transfer element

A gas-liquid mass transfer and element technology, applied in the field of gas-liquid mass transfer elements of rectification trays, can solve problems such as affecting tray efficiency, increasing tray pressure drop, obstruction and disturbance, and simplifying design and processing difficulties , Avoid large liquid level drop, strengthen the effect of promoting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

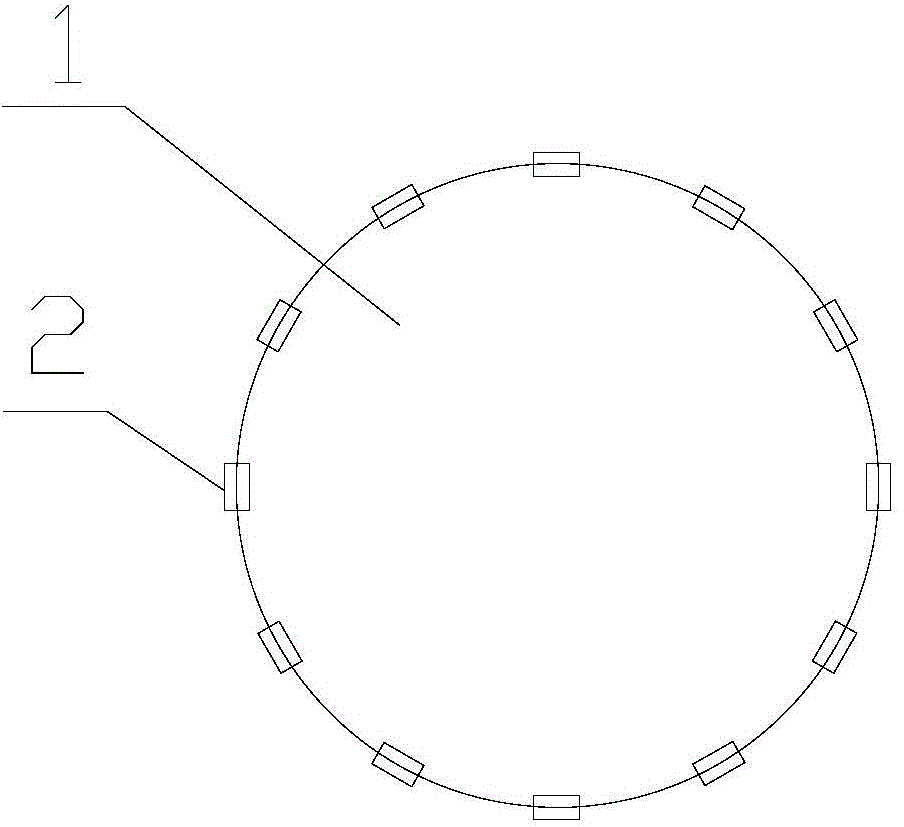

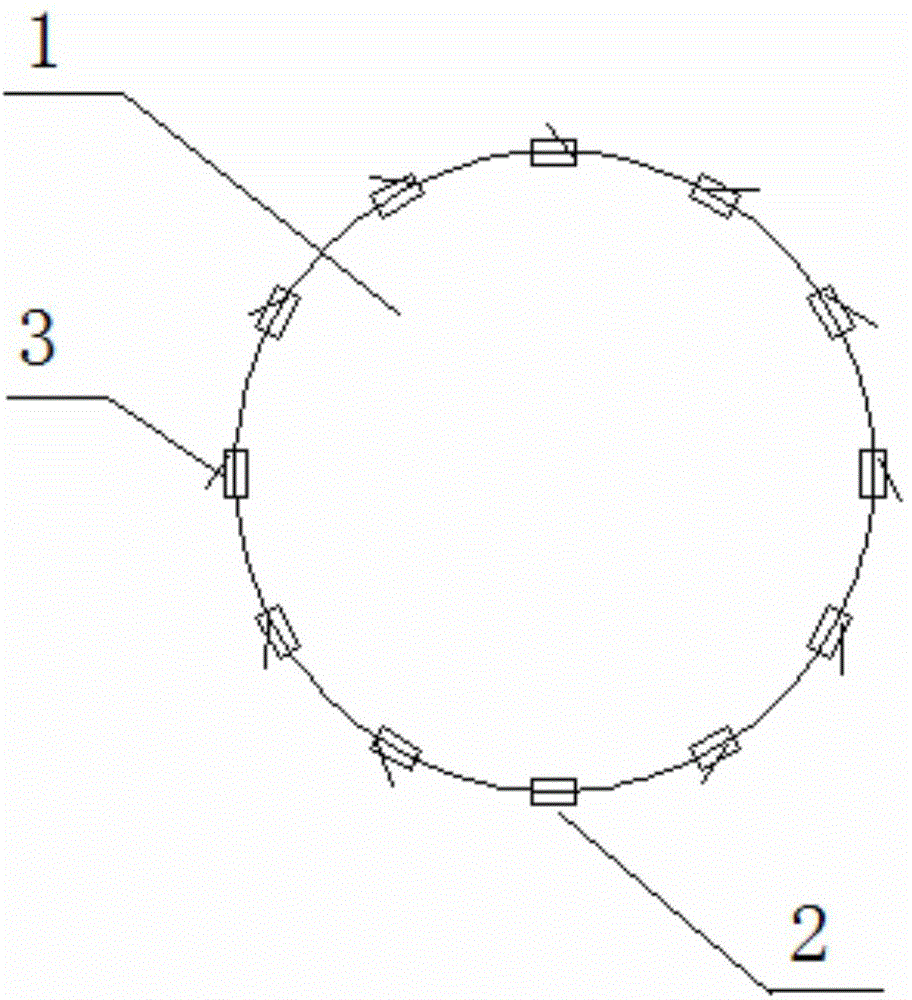

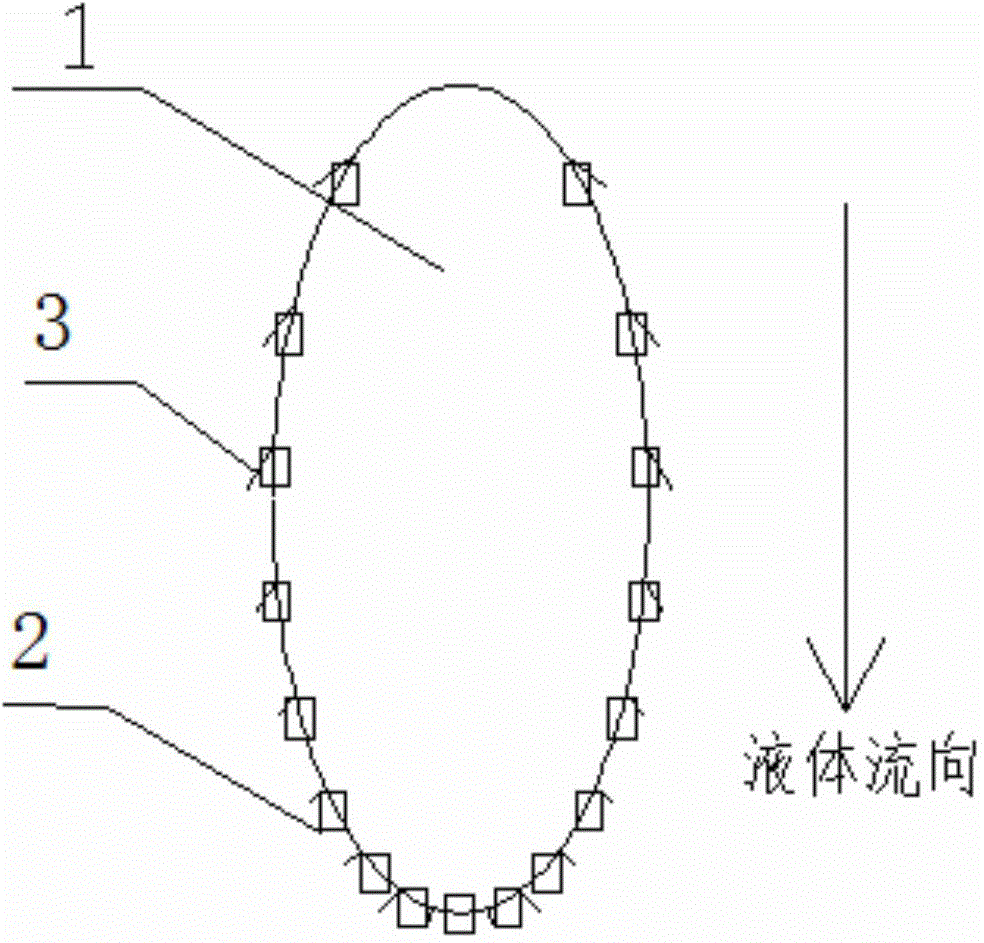

[0048] Benzene-carbon tetrachloride separation system. The original tower diameter is 500mm, single downcomer type, the downcomer section shape is bow-shaped, and the downcomer area accounts for 10%; standard DN80 bubble caps are used, and each tray has 36 bubble caps, arranged in 5 rows. There are 12 boards. Adopting the present invention, the tower diameter and the form of the tray remain unchanged, and it is still a single downcomer type, and the downcomer, plate spacing, weir length, number of trays, riser height, cap height, etc. are all unchanged; the original Blister (round blister with air outlet slits, as attached figure 1 (as shown in the schematic diagram) is replaced by a streamlined oval-shaped guide hole blister, the schematic diagram is attached image 3 , the side facing the overflow weir has denser openings. The opening direction of the tooth gap and the straight line direction from the inlet weir to the outlet weir form an angle of 45-0 degrees, and the an...

Embodiment 2

[0051] Ethanol-water rectification system. The diameter of the original tower is 1200mm, a total of 38 trays, the opening rate is 12%, the plate spacing is 450mm, and the traditional F1 float valve is used. Keep the opening ratio and the plate spacing constant, only use the whale-shaped guide float valve among the present invention (as attached Figure 5 As shown) the tray replaces the original tray (as attached Figure 4 shown). The float valve is whale-shaped and streamlined, which gradually changes from thick to thick at the front and thin at the back. The valve length is 100mm, the front end is 35mm, the rear end is 65mm, and the maximum width is 45mm. There are 2 guide holes on the valve cover, with a height of 3mm and a width of 20mm, in the shape of a solid valve facing the direction of the overflow weir. The front legs are 8mm wide and 12mm long, and the rear legs are the same. There is a baffle perpendicular to the bonnet under the bonnet, the shape is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com