The bolt lock chain control method of the high pressure water gun pumping station

A technology of high-pressure water guns and high-pressure water pumps, which is applied to liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as difficult to withstand pressure shocks, poor reliability, and poor safety, and achieve pressure relief. Fast loading, stable and reliable performance, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

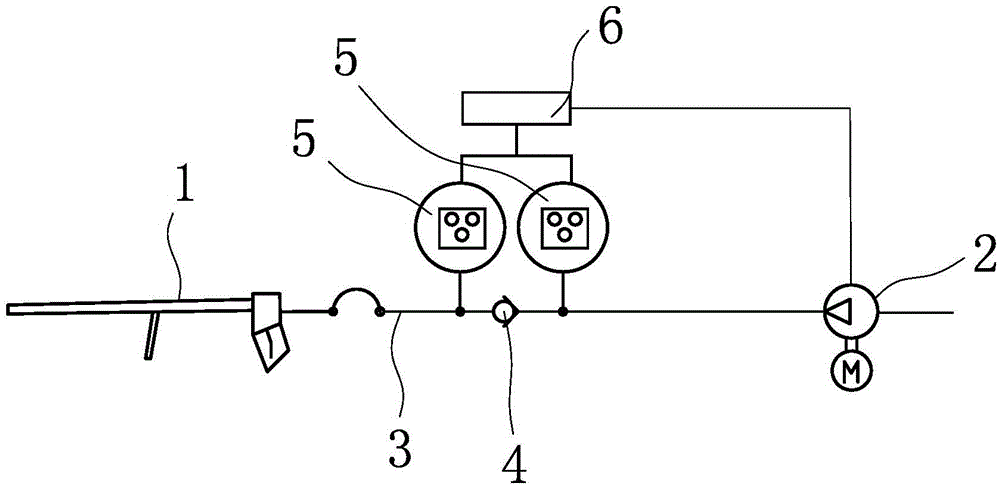

[0020] like figure 1 As shown, a bolt chain control method of a high-pressure water gun pumping station is characterized in that it comprises the following steps:

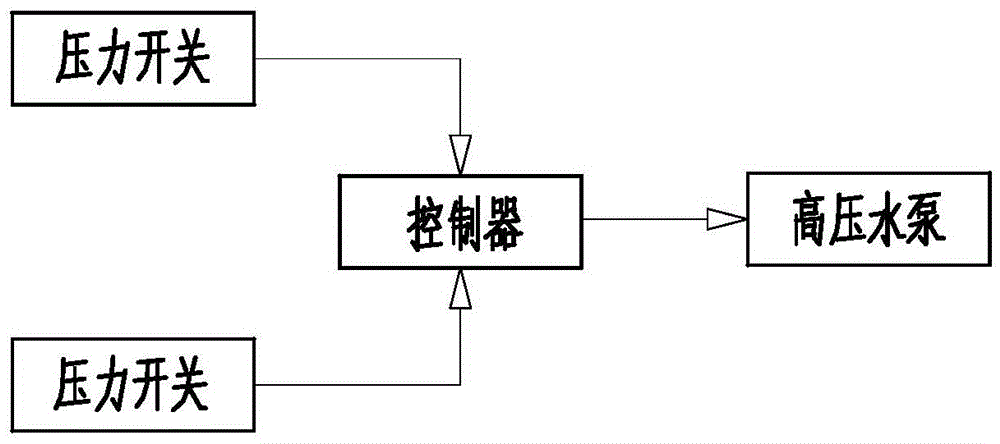

[0021] A. A one-way valve 4 is set on the water supply pipeline 3 connecting the high-pressure water gun 1 and the high-pressure water pump 2, and a pressure switch 5 is respectively set on both sides of the one-way valve 4, and the output ends of the two pressure switches 5 are connected to the controller 6, The output relay of the controller 6 is connected to the high-pressure water pump 2, and sets different pressure setting values for the two pressure switches 5;

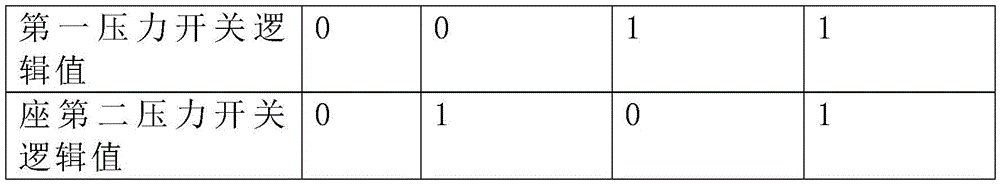

[0022] B. Set the control logic of the controller 6 as follows: when the two pressure switches 5 detect no pressure signal at the same time, that is, when the logic value is 0, the logic value of the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com