Lengthening-remolding method of automotive parts

A technology of auto parts and parts, which is applied in the field of lengthening and restructuring of auto parts, can solve the problems of reduced fatigue strength of parts, short life of parts, hidden safety hazards, etc., to control welding deformation and stress concentration, improve fatigue limit, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The length of a certain component on an existing automobile is 1200mm. For the purpose of new product design and development, it needs to be lengthened by 60mm, that is, the total length reaches 1260mm.

[0036] The above-mentioned auto parts are lengthened, and the method for lengthening and remanufacturing thereof comprises the following steps:

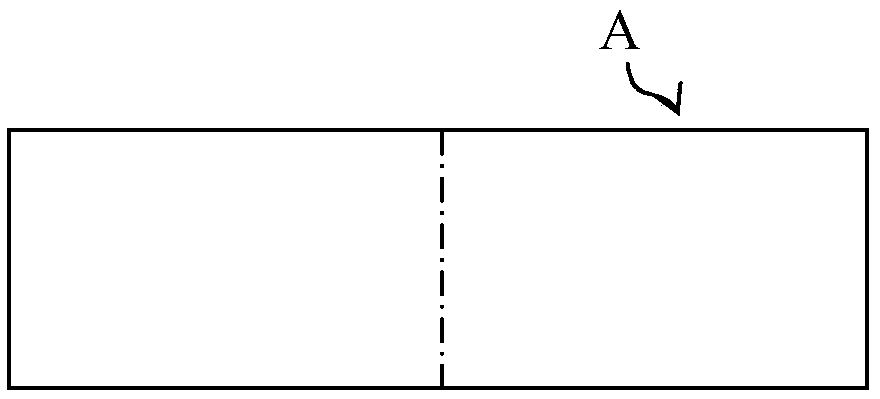

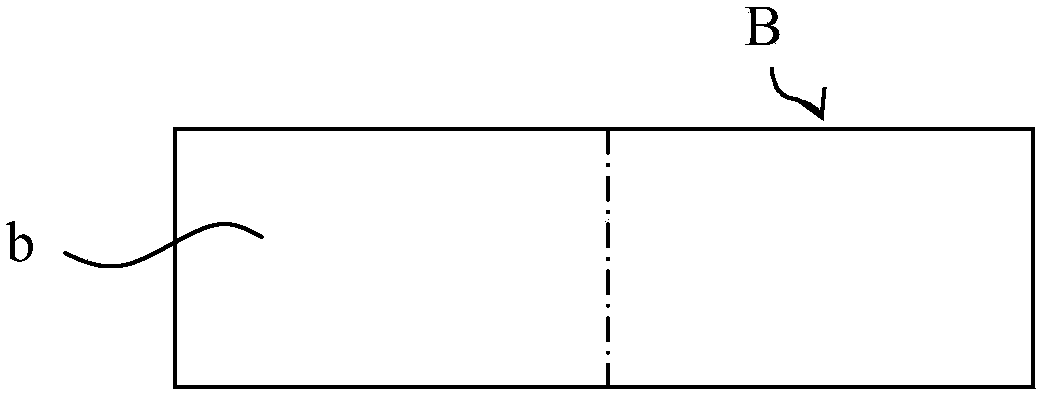

[0037] 1) if figure 1 with figure 2 As shown in , select two identical parts to be processed and divide them into the first part A and the second part B;

[0038] 2) if figure 1 with figure 2 , mark the longitudinal centerlines of the first part A and the second part B respectively;

[0039] 3) if figure 2 As shown, the second part B is cut along the longitudinal centerline of the second part B, and the left part after cutting is selected as the left part b;

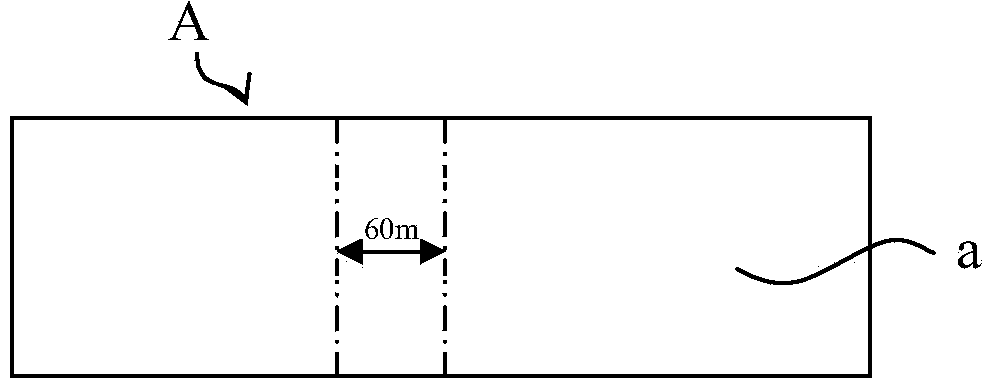

[0040] 4) if image 3 As shown, taking the longitudinal centerline of the first part A as the reference, along the length direction of the first part A, offse...

Embodiment 2

[0048] For the auto parts in the first embodiment, another method for lengthening and reforming the auto parts includes the following steps:

[0049] 1) if figure 1 with figure 2 As shown in , select two identical parts to be processed and divide them into the first part A and the second part B;

[0050] 2) if figure 1 with figure 2 , mark the longitudinal centerlines of the first part A and the second part B respectively;

[0051] 3) if figure 2 As shown, the second part B is cut along the longitudinal centerline of the second part B, and the left part after cutting is selected as the left part b;

[0052] 4) if image 3 As shown, taking the longitudinal centerline of the first part A as the reference, along the length direction of the first part A, offset 60mm to the left, and mark the longitudinal cutting line on the first part A;

[0053] 5) if image 3 As shown, cut along the longitudinal cutting line of the first part A, and select the right part after cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com