A fully automatic oval tube loading machine

An oval tube, fully automatic technology, applied in coating and other directions, can solve the problems of artificial pollution, inability to achieve automatic tube loading, slow production speed, etc., to save labor costs, avoid artificial pollution, production fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

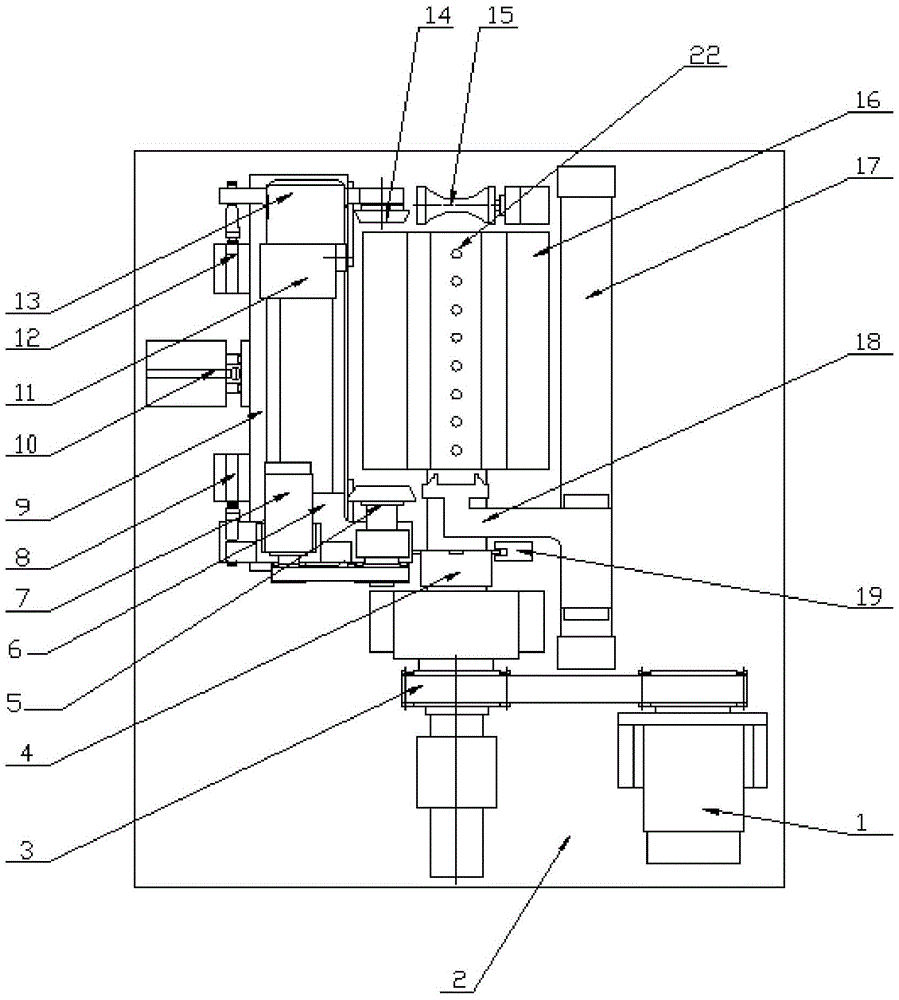

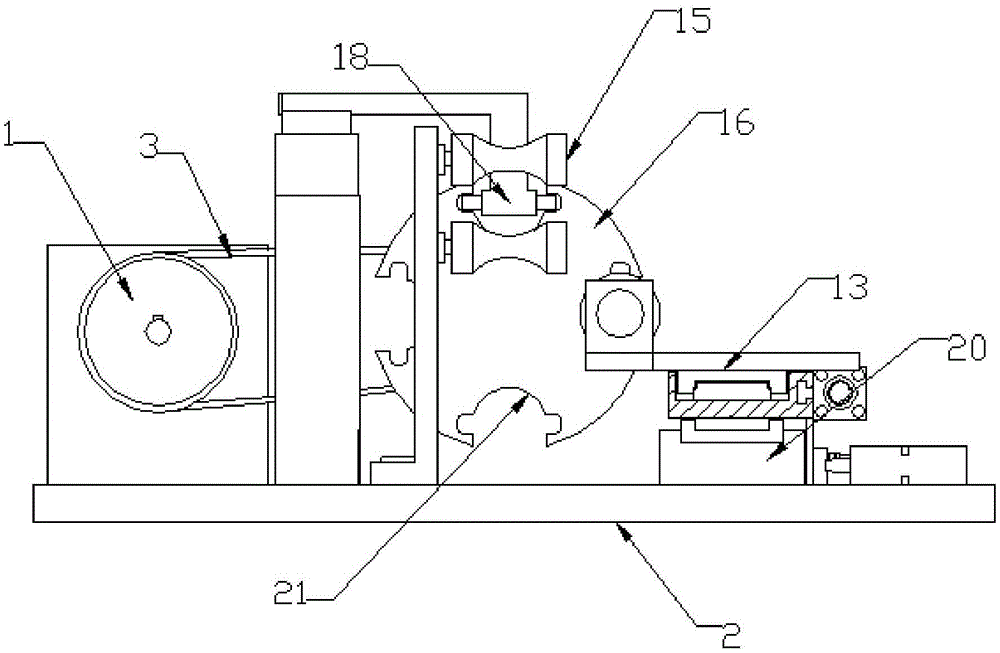

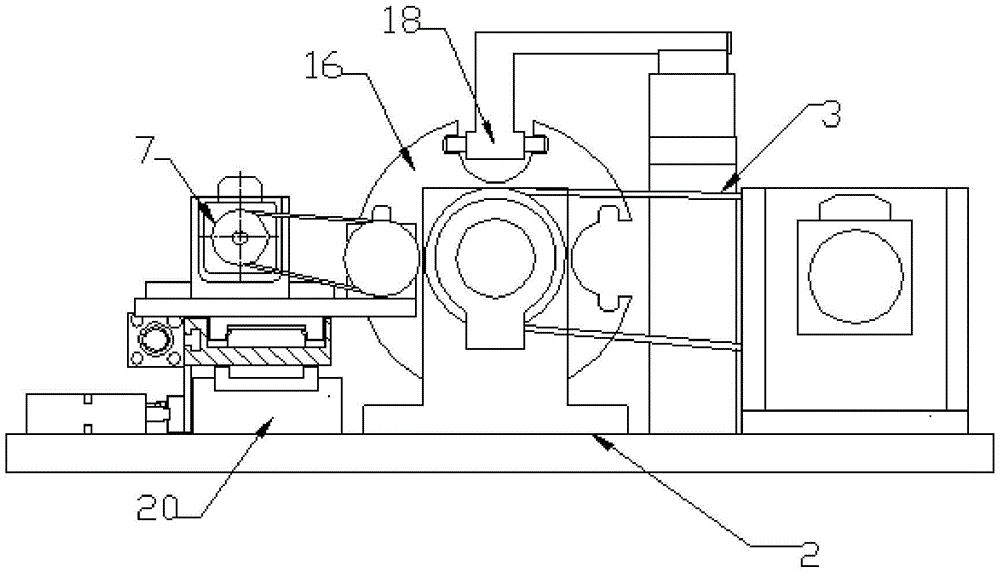

[0029] A fully automatic elliptical tube loading machine is used to realize the automatic loading function of elliptical tubes of a fully automatic shoulder injection machine, such as Figure 1-3 As shown, it includes a rack, a positioning mechanism, a pipe feeding mechanism, a calibration mechanism and an upper pipe mechanism, wherein the rack is provided with a mounting base plate 2; the positioning mechanism includes a vacuum indexing wheel 16 fixed on the mounting base plate 2 and a vacuum indexing wheel The receiving tube position, the calibration position and the upper tube position are arranged in the circumferential direction of the wheel 16, and a plurality of working grooves 21 are evenly arranged on the outer surface of the vacuum indexing wheel 16 along the circumferential direction. The working slot 21 corresponds to the receiving position, the marking position and the upper pipe position, respectively.

[0030] In this implementation, in order to facilitate the u...

Embodiment 2

[0038] All the other are identical with embodiment 1, and difference is, as Figure 4 As shown, the inner surface of the working groove 21 is provided with a positioning groove 23. The positioning groove 23 corresponds to the shape of the positioning pin 24 on the side of the upper pipe claw. When the upper pipe claw 18 pushes the hose to the forming pressure roller 15, no position deviation.

Embodiment 3

[0040] The rest is the same as that of Embodiment 2, except that an adjustment device is provided on the tube pressing device, and when the tube diameters of the hoses are different, the distance between the two forming pressure rollers can be adjusted correspondingly according to the tube diameters.

[0041] In the above-mentioned embodiment, the number of working grooves of the vacuum indexing wheel can be selected according to the actual needs of production, and the positions of the controlled position, the marked position and the upper tube position can also be set according to the actual production needs. The above-mentioned embodiment It is only one of them, but the setting principle of the present invention is not limited to this embodiment.

[0042] Beneficial effects of adopting the technical solution disclosed in the present invention: the vacuum indexing wheel is provided with a plurality of stations of the tube position, the calibration position and the upper tube p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com