Adaptive Tire Blast Support System

A support system and self-adaptive technology, applied in tire parts, transportation and packaging, vehicle parts, etc., can solve problems such as high cost and reduced tire shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

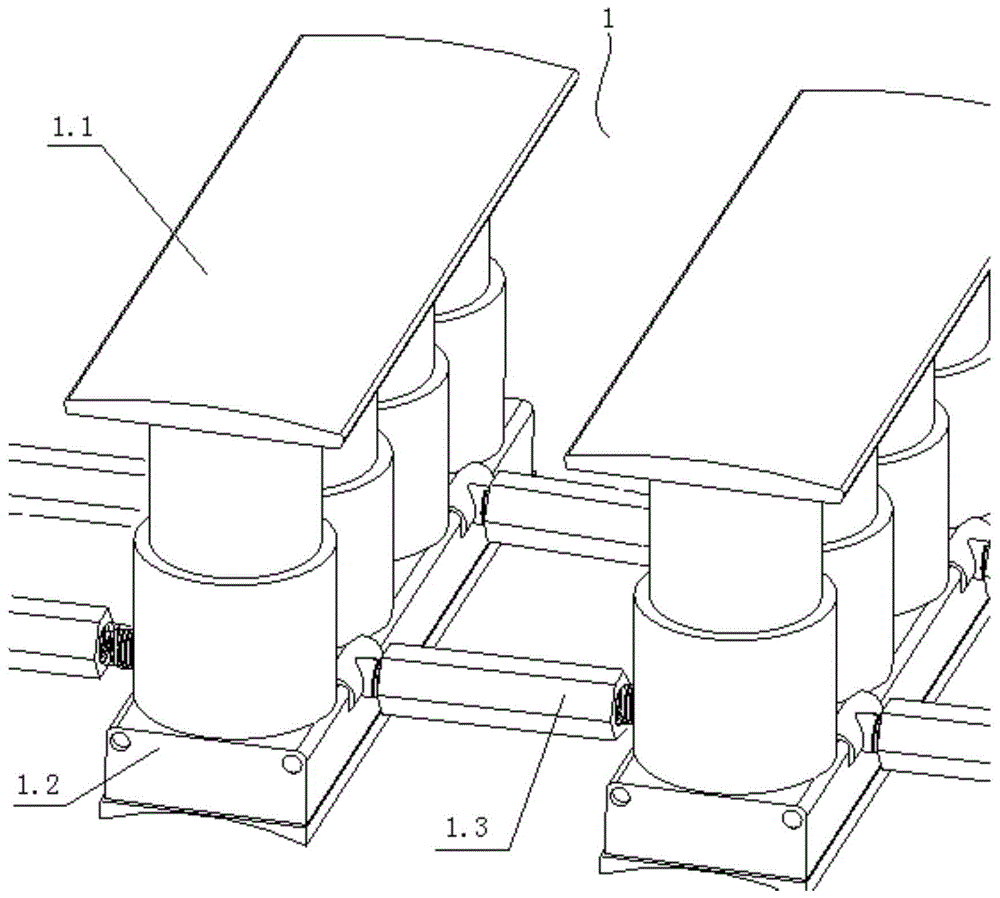

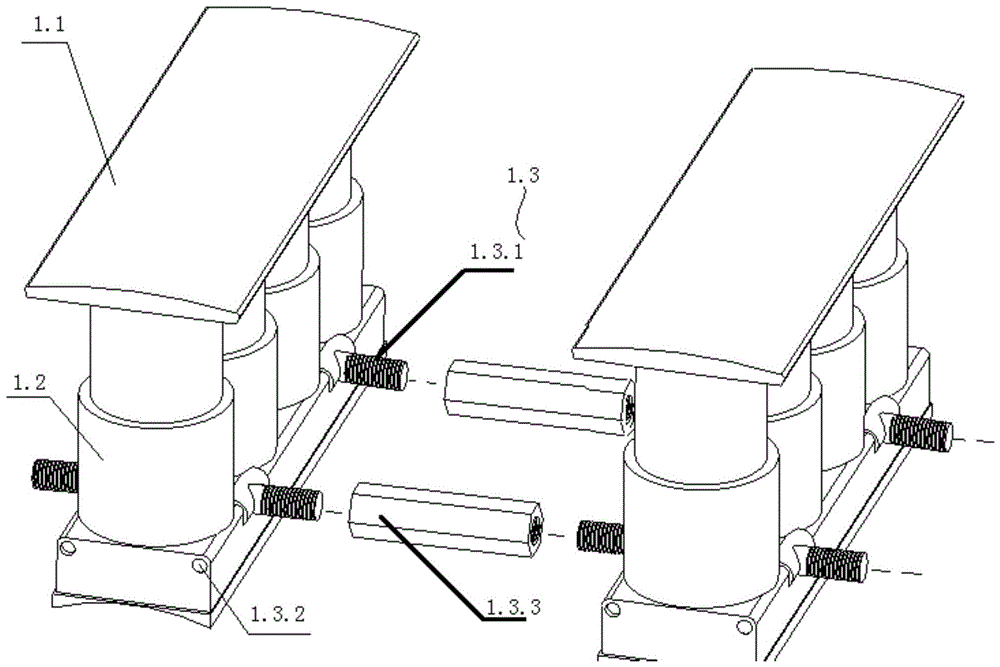

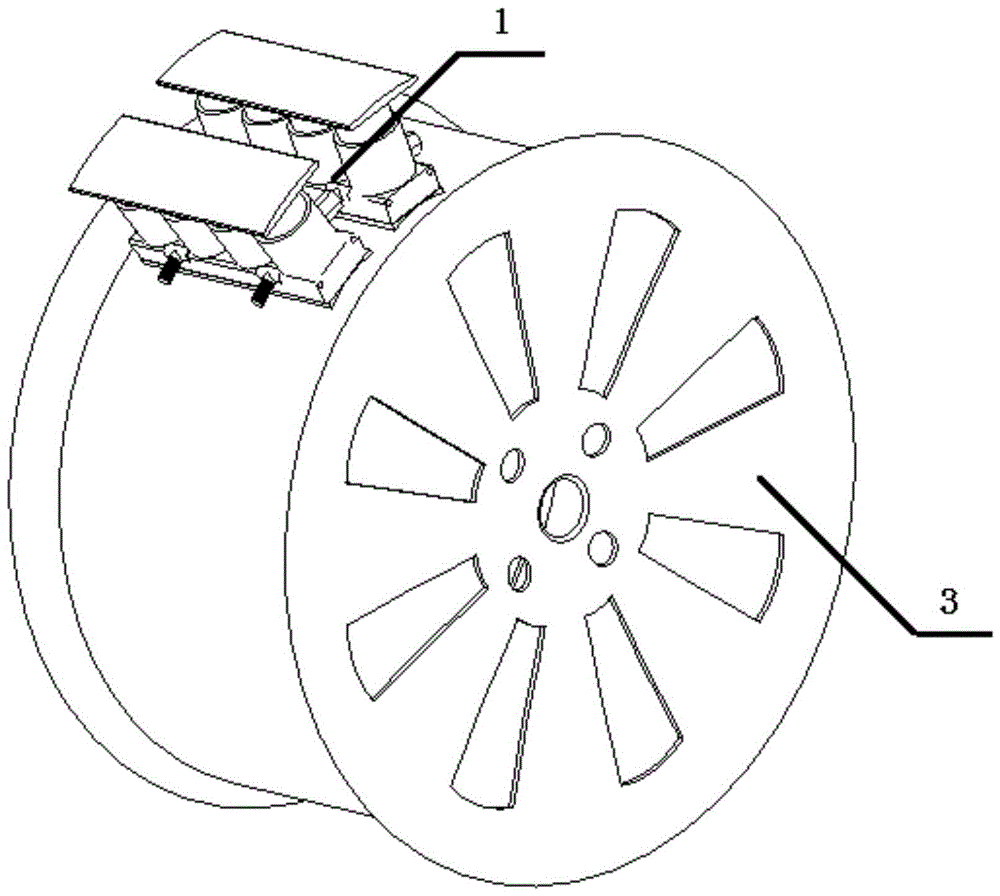

[0047] An adaptive tire explosion-proof support system 1, including 20 cylinder support units, each cylinder support unit includes a sub-cylinder assembly 1.1, a master cylinder assembly 1.2,

[0048]The sub-cylinder assembly 1.1 includes a top seat 1.1.1 and four sub-cylinder bodies 1.1.2 arranged side by side, the top of each sub-cylinder body 1.1.2 is connected to the top seat 1.1.1, and each sub-cylinder body 1.1. The bottoms of 2 are respectively provided with sealing grooves, and sealing rings 1.1.3 are installed in the sealing grooves; the master cylinder assembly 1.2 includes base 1.2.1 and master cylinders with the same number as the sub cylinders 1.1.2 and arranged side by side Body 1.2.2, the bottom of the mother cylinder 1.2.2 is fixed on the base 1.2.1, the base 1.2.1 is provided with 2 grooves along the horizontal direction, and the two sides of the base 1.2.1 are respectively provided with a pin hole along the longitudinal direction ; The bottom of each of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com