A device and method for adjusting the balance of the conduction belt

A technology of balance adjustment and guide belt, which is applied in the direction of transportation, packaging, and conveyors. It can solve problems such as large fluctuations, reduced guide belt life, and graded deviation correction, so as to reduce the frequency of intervention, improve real-time monitoring, and extend the guide belt. Effect with life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

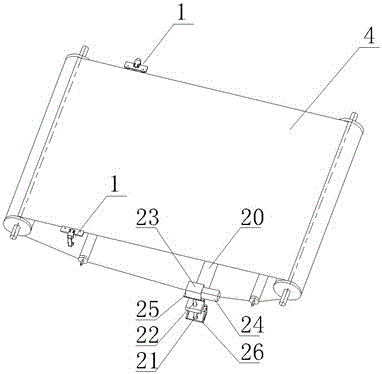

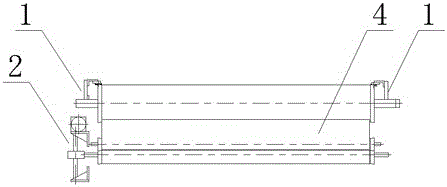

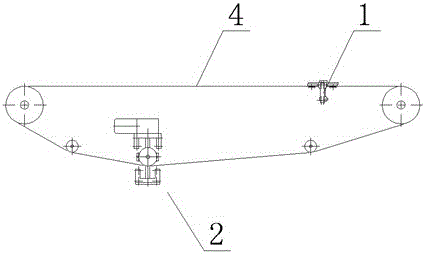

[0048] see Figure 1-Figure 8 As shown, a guide belt balance adjustment device of the present invention is mainly composed of a detection mechanism 1 , a deviation correction mechanism 2 , and a control mechanism 3 .

[0049] The detection mechanism 1 is installed on both sides of the guide belt 4, and is symmetrically arranged, and is used to detect whether the guide belt 4 is offset. The detection mechanism 1 of the present invention adopts a pressure detection mechanism. By detecting the pressure on both sides of the guide belt 4, it can be judged Whether the conduction band 4 is offset. The detection mechanism 1 can adopt a pressure sensor.

[0050] In order to make the pressure detection on both sides of the conduction belt 4 more real-time and accurate, Figure 3-5 In the preferred embodiment shown, the detection mechanism 1 includes a guide wheel 10 for contacting the guide belt 4, a slider 11 connected to the guide wheel 10, a spring 12 connected to the slider 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com