Lithium battery discharging control system based on PLC and HMI technology

A technology of control system and lithium battery, which is applied in the direction of conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems of production efficiency obstacles, no blanking equipment, etc., and achieve improved production efficiency, flexible use, and practical expansion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The lithium battery unloading control system based on PLC and HMI technology provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

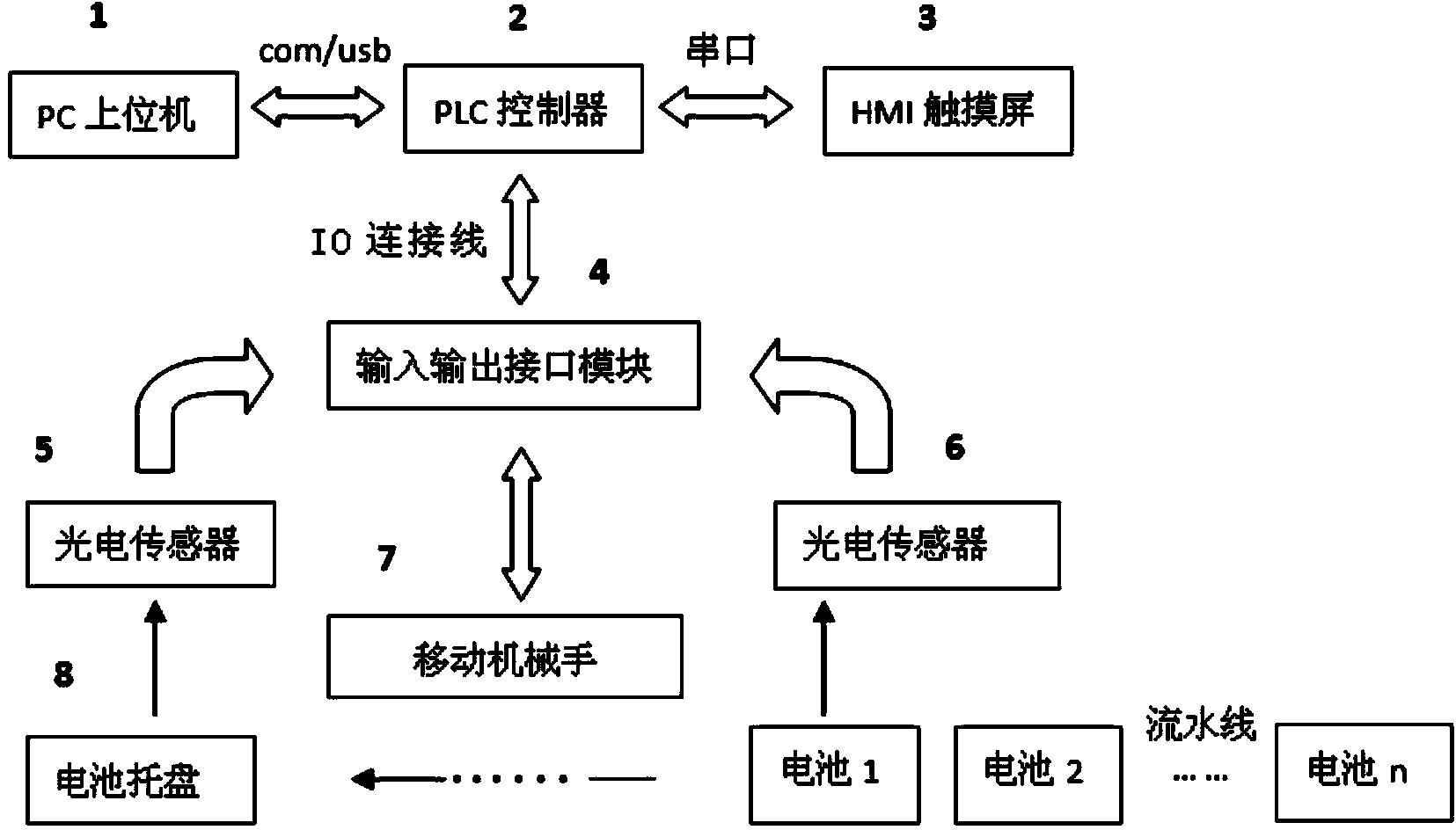

[0015] Such as figure 1 As shown, the lithium battery blanking control system based on PLC and HMI technology provided by the present invention includes: PC upper computer 1, PLC controller 2, HMI touch screen 3, input and output interface module 4, first photoelectric sensor 5, second photoelectric sensor 6. Mobile manipulator 7 and battery tray 8; wherein: PC upper computer 1 is the upper operation management platform, which is connected to PLC controller 2 through COM / USB port; HMI touch screen 3 is the user operation interface, which is connected to PLC through RS232 communication port Controller 2 is connected; PLC controller 2 is the core controller of this system, and it is connected with input-output interface module 4 by IO connection line; Input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com