Vertical-layout single-array hot wire device for preparing diamond film

A diamond film, vertical layout technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve problems such as diamond film generation quality affecting the tool, unstable hot wire coating, and lower electrode plate shaking. , to achieve reliable long-term use, facilitate uniform coating, and improve the effect of use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

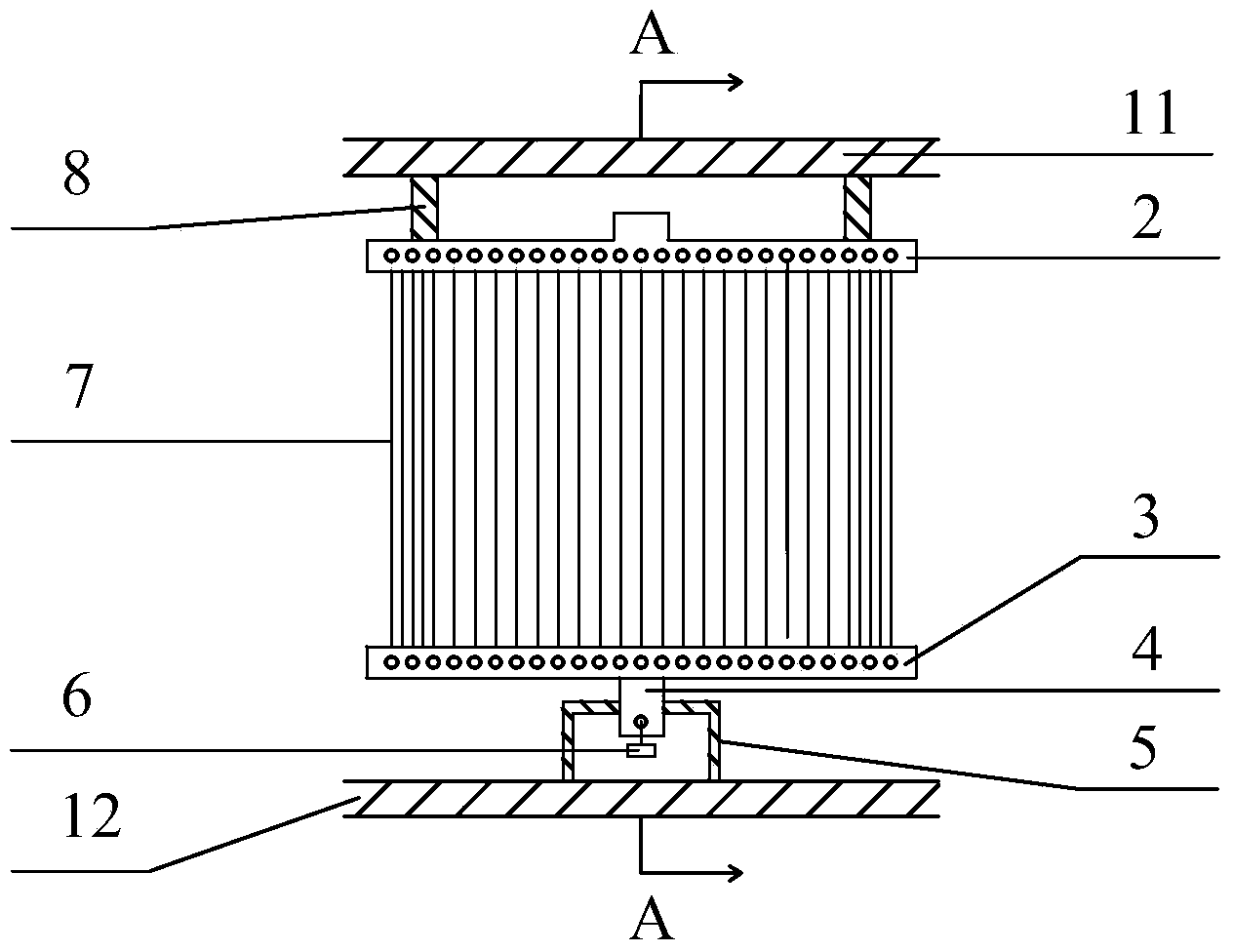

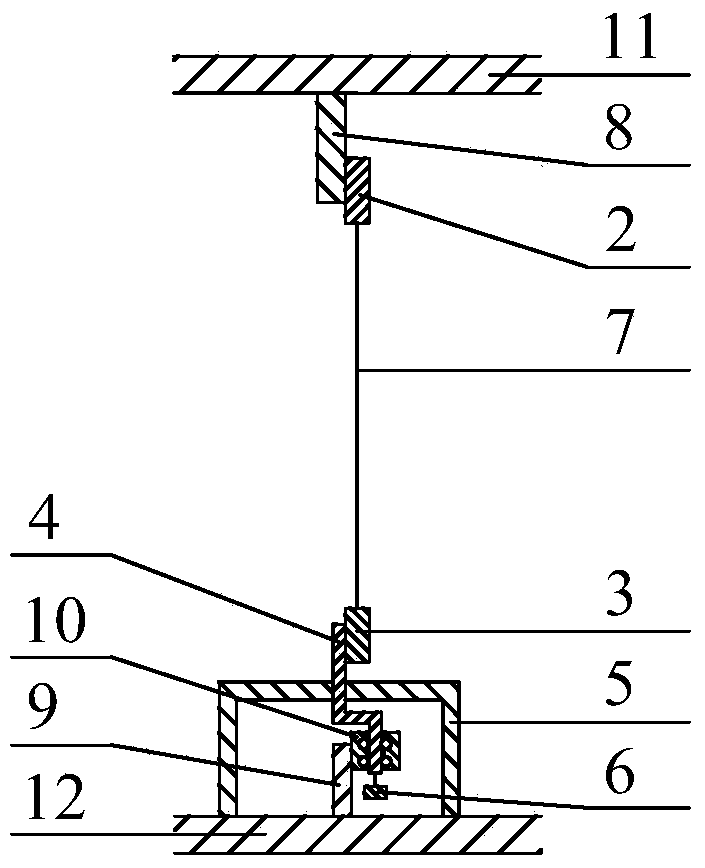

[0026] Such as figure 1 with 2 A single-array hot wire device for preparing diamond films in a vertical layout is shown, including a vacuum chamber upper wall 11 and a vacuum chamber lower wall 12, the upper electrode plate 2 is fixedly connected to the vacuum chamber upper wall 11; a single row of hot wires 7 Vertically distributed, its upper end is fixedly connected to the upper electrode plate 2 and its lower end is fixedly connected to the lower electrode plate 3; the lower end of the lower electrode plate 3 is fixed on the hot wire force adjustment mechanism, and the hot wire force adjustment mechanism is fixed under the vacuum chamber Above the siding 12.

[0027] The upper electrode plate 2 is fixedly connected to the upper wall plate 11 of the vacuum chamber through a fixing bracket.

[0028] The distribution of the single row of hot wires 7 is:

[0029] At the two ends of the upper electrode plate and the lower electrode plate, perpendicular to the upper electrode plate and...

Embodiment 2

[0033] Such as figure 1 with 2 A single-array hot wire device for preparing diamond films in a vertical layout is shown, including a vacuum chamber upper wall 11 and a vacuum chamber lower wall 12, the upper electrode plate 2 is fixedly connected to the vacuum chamber upper wall 11; a single row of hot wires 7 Vertically distributed, its upper end is fixedly connected to the upper electrode plate 2 and its lower end is fixedly connected to the lower electrode plate 3; the lower end of the lower electrode plate 3 is fixed on the hot wire force adjustment mechanism, and the hot wire force adjustment mechanism is fixed under the vacuum chamber Above the siding.

[0034] The upper electrode plate 2 is fixedly connected to the upper wall plate 11 of the vacuum chamber through a fixing bracket.

[0035] The distribution of the heating wires 7 in a single row is as follows: at the two ends of the upper electrode plate and the lower electrode plate, perpendicular to the upper electrode pla...

Embodiment 3

[0039] Such as figure 1 with 2 A single-array hot wire device for preparing diamond films in a vertical layout is shown, including a vacuum chamber upper wall 11 and a vacuum chamber lower wall 12, the upper electrode plate 2 is fixedly connected to the vacuum chamber upper wall 11; a single row of hot wires 7 Vertically distributed, its upper end is fixedly connected to the upper electrode plate 2 and its lower end is fixedly connected to the lower electrode plate 3; the lower end of the lower electrode plate 3 is fixed on the hot wire force adjustment mechanism, and the hot wire force adjustment mechanism is fixed under the vacuum chamber Above the siding.

[0040] The upper electrode plate 2 is fixedly connected to the upper wall plate 11 of the vacuum chamber through a fixing bracket.

[0041] The distribution of the heating wires 7 in a single row is as follows: at the two ends of the upper electrode plate and the lower electrode plate, perpendicular to the upper electrode pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com