Self-resetting damper of micro-vibration energy dissipation part

A self-reset, micro-vibration technology, applied in building components, earthquake-proof and other directions, can solve the problems of increasing building maintenance costs and the impact of repair costs, and achieve the effects of simple production, control of residual deformation, and reduction of residual deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

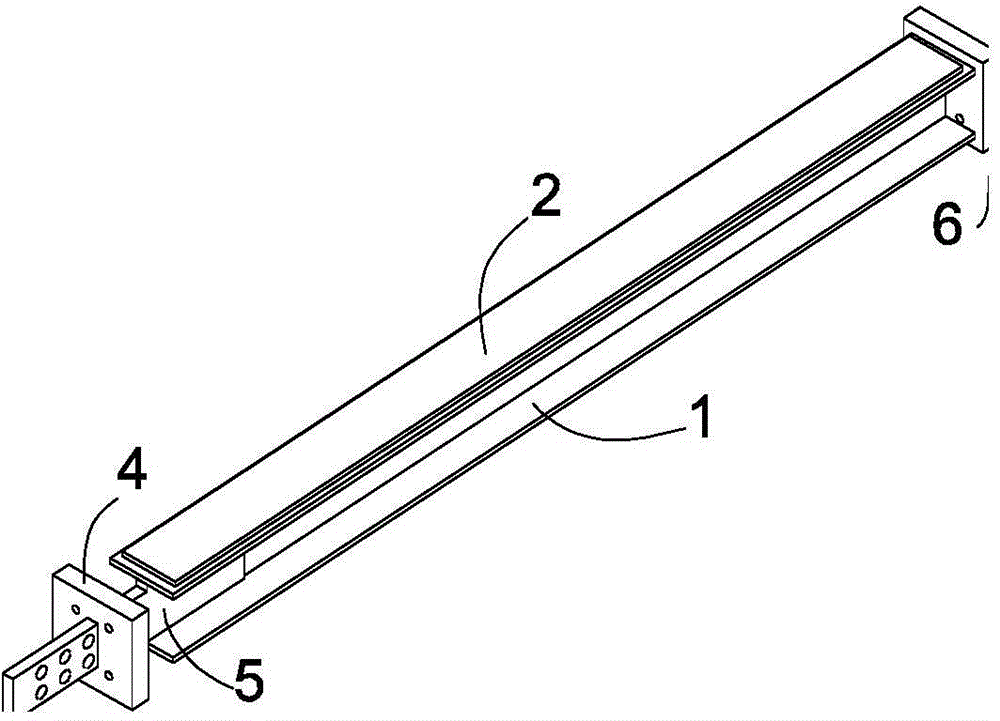

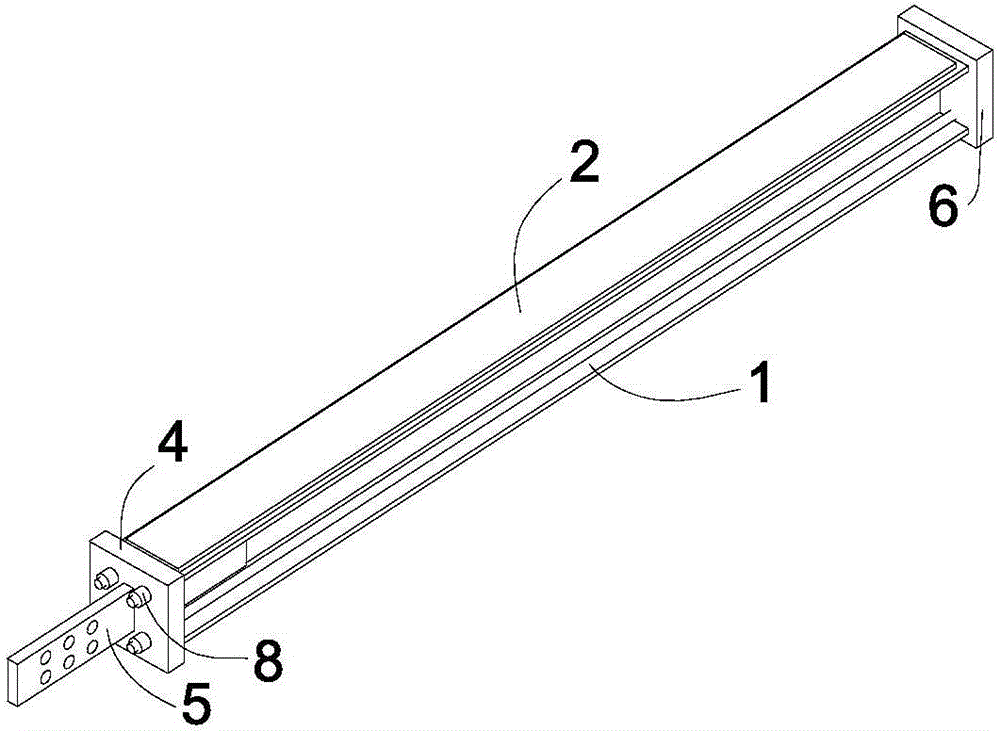

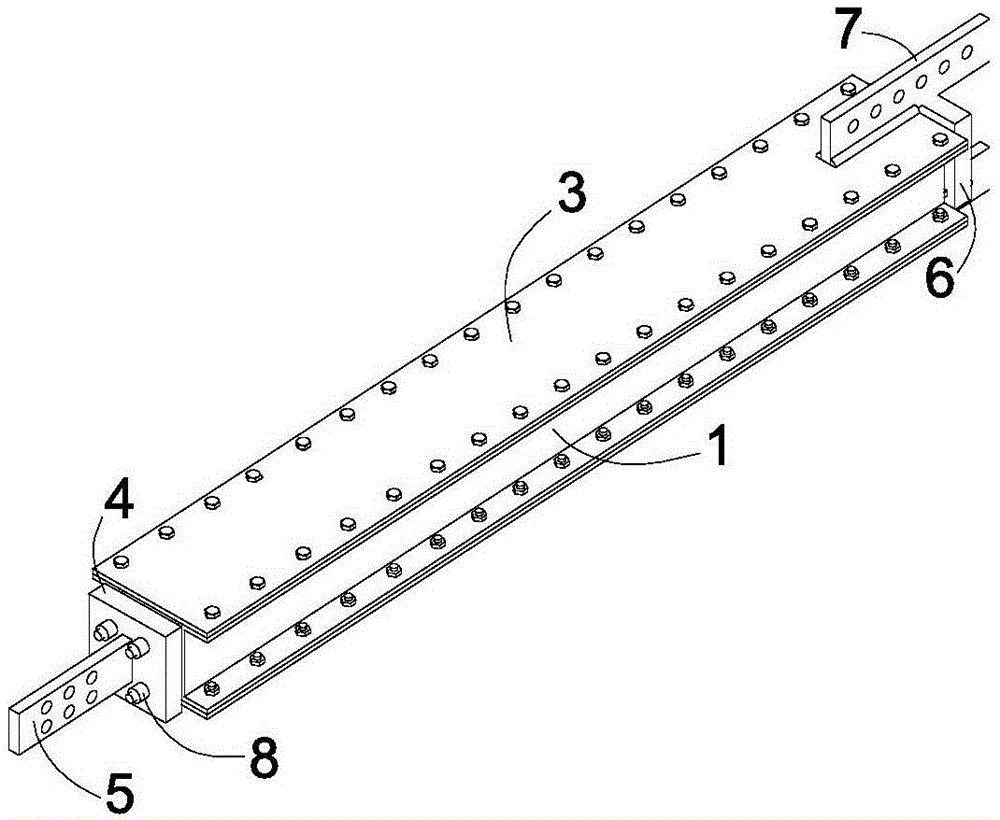

[0028] Such as Figure 1-6 As shown: the self-resetting damper of the micro-vibration energy dissipation part in this embodiment is composed of an inner restraint component 1, a damping material body 2, an outer restraint component 3, an anchor plate 4, a connecting plate 5, an anchor plate 2 6, and a connecting plate Two 7 and a tension system 8, the damping material body 2 is located between the inner constraint component 1 and the outer constraint component 3, the outer surface of the inner constraint component 1 is fixed to the damping material body 2, and the inner surface of the outer constraint component 3 is connected to the damping material The body 2 is fixed, and along the length direction of the inner restraint part 1 or the outer restraint part 3, the inner restraint part 1 is longer than the outer restraint part 3 by a certain distance at both ends, and the tension system 8 is anchored on the anchor plate 1 and the anchor plate 2 6, simultaneously press the ancho...

Embodiment 2

[0030] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 lies in that the cross section of the inner constraint member 1 is a rectangular tube.

Embodiment 3

[0032] Such as Figure 8 As shown, the difference between the present embodiment and the second embodiment is that the damping material body 2 is divided into four pieces, which are located around the inner restraint part 1 and the outer restraint part 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com