Visual nozzle

A nozzle and transparent glass technology, which is used in the testing of fuel injection devices, machinery/structural components, instruments, etc. The effect of experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

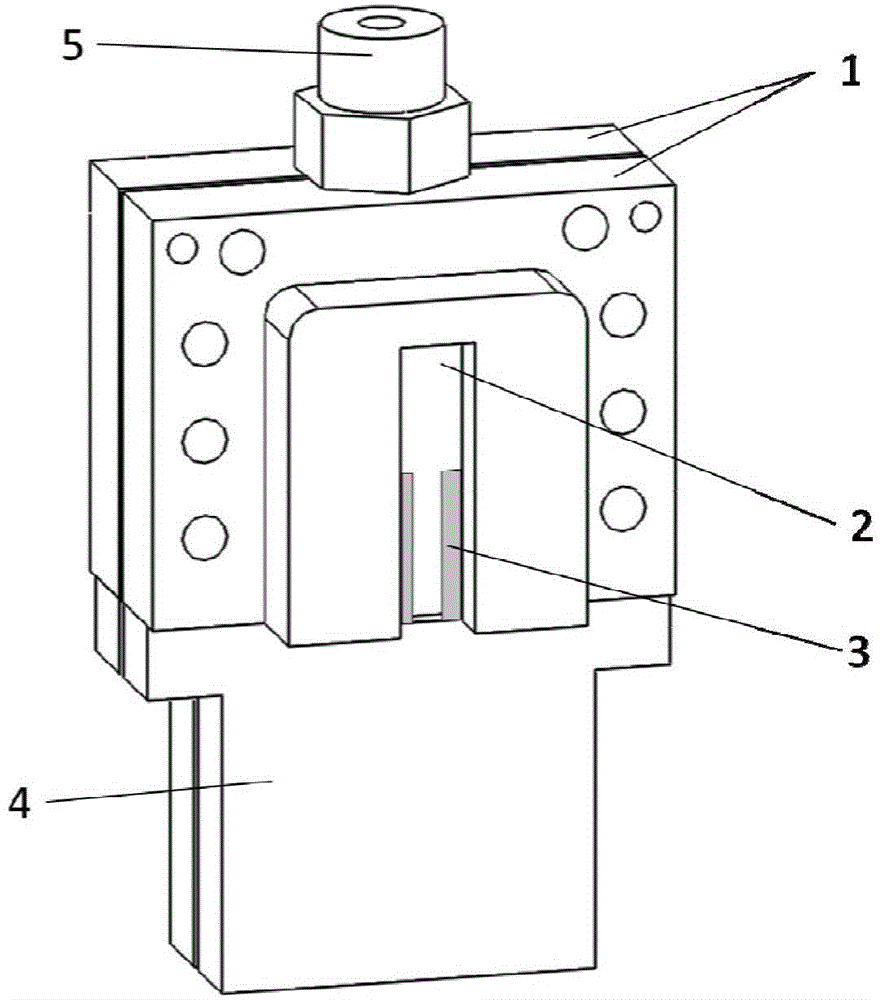

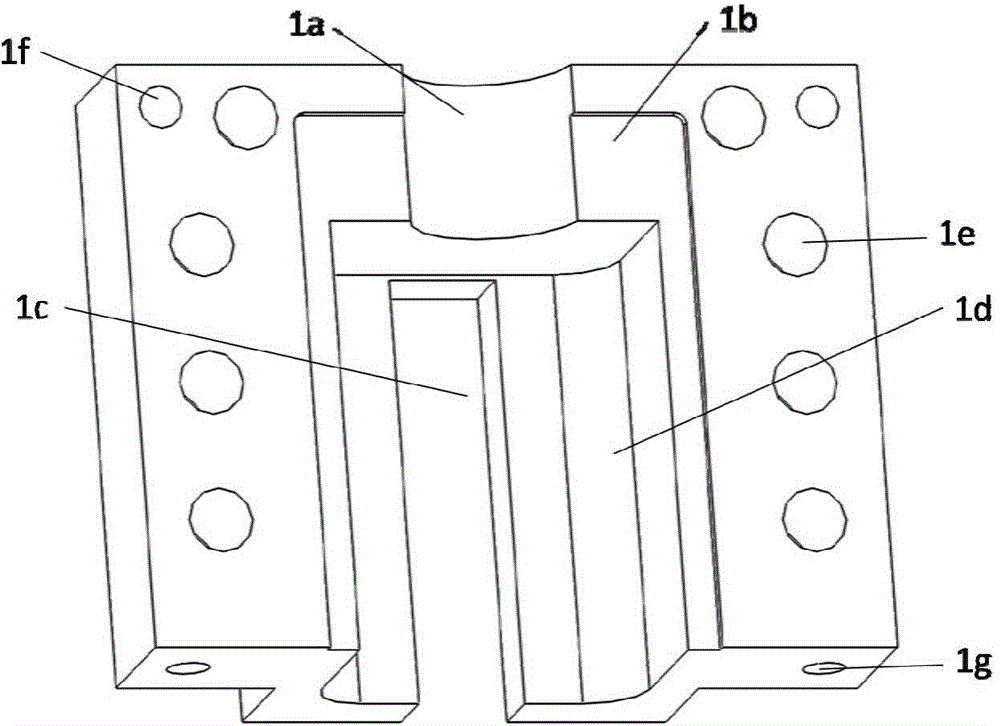

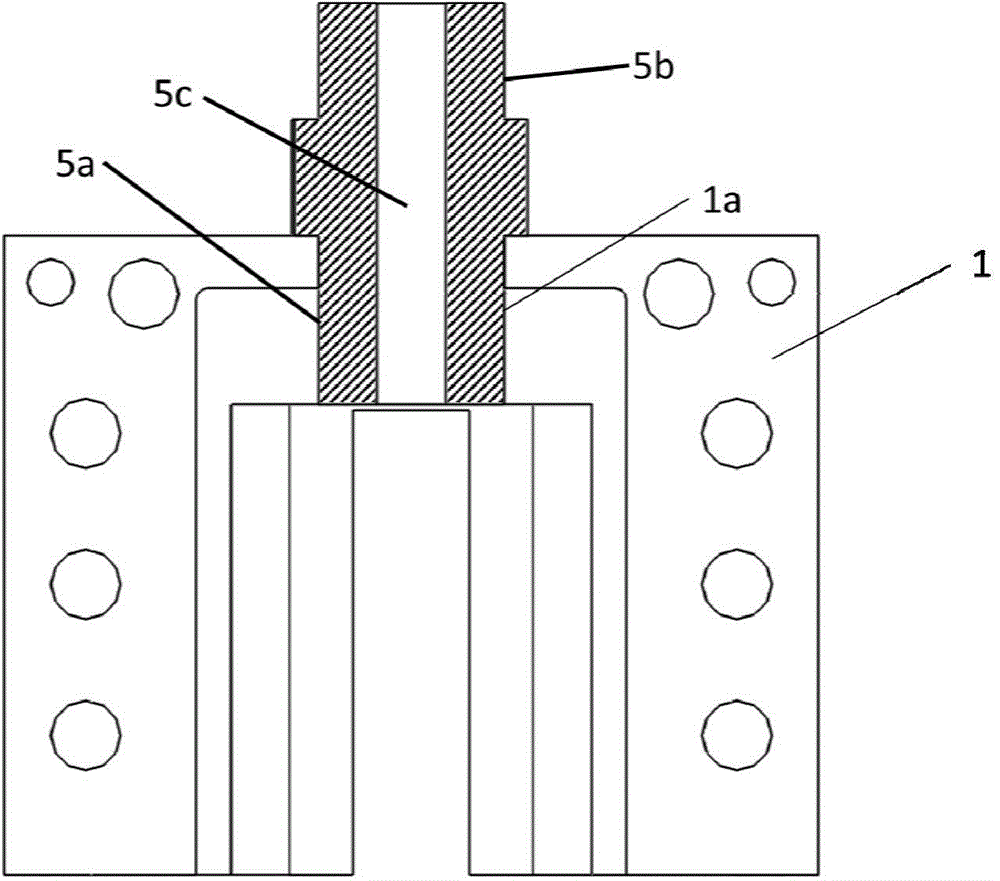

[0025] Please see first figure 1 , figure 1 It is an assembly diagram of the present invention. As shown in the figure, a visual nozzle includes: a nozzle body, an adapter 5 and an extension transparent glass 4. The nozzle body is two clamp bodies 1 that are combined and fastened. The block holder body 1 clamps two pieces of main body transparent glass 2, precision gasket 3 and its sealed rubber gaskets 6a, 6b. The longitudinal slit 7 of the precision gasket 3 is connected with the two pieces of main body transparent glass. 2 constitutes the inner channel of the visible nozzle, the top of the nozzle body is connected to the adapter 5, and the bottom is connected to the extension transparent glass 4 to form the outer channel of the nozzle; the shape of the precision gaske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com