Suspended rotary water pressure energy converted power output device

A power output and water pressure technology, applied in the field of suspended rotary water pressure energy conversion power output device, can solve the problems of poor operability and controllability, limited use of geographical environment, unsuitable for industrial production and power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

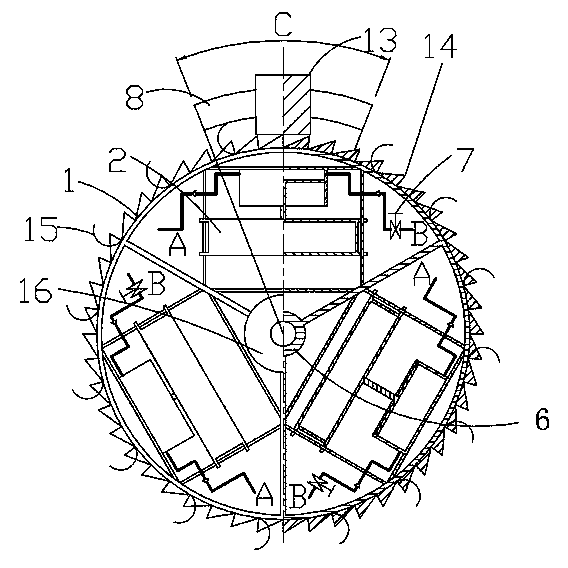

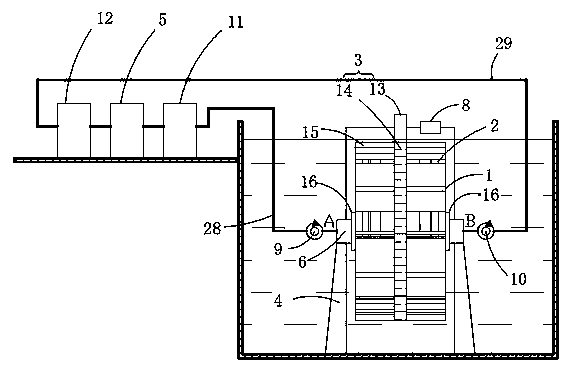

[0017] The present invention includes an energy converter 2 fixedly connected with the rotating shaft 6, a ring frame 1 concentric with the rotating shaft 6 and fixedly connected, an overturning mechanism 3, a support 4 and a hydraulic transmission mechanism. The transmission mechanism is composed of a hydraulic cylinder 19, check valves 24, 25, oil pipes 26, 27, a hydraulic oil tank 11, a high-pressure oil accumulator 12 and a hydraulic actuator 5.

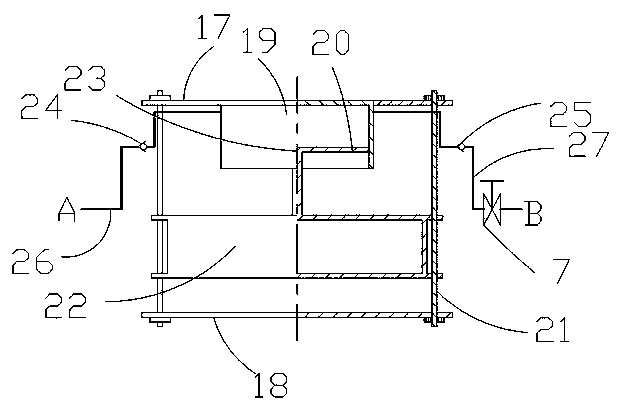

[0018] The energy converter 2 includes a buoy 22, upper and lower base plates 17, 18, a hydraulic cylinder 19 and a piston 20; the upper and lower base plates 17, 18 are connected and fixed by at least two fixing rods 21, and the hydraulic cylinder 19 is installed on the upper base plate 17; The upper end of the buoy 22 is provided with a connecting rod 23, which is connected with the piston 20 of the hydraulic cylinder 19 installed on the upper base plate 17; The oil inlet of the hydraulic cylinder 19 is equipped with a check va...

Embodiment 2

[0026] The structure of the energy converter in the second embodiment is different from that of the energy converter in the first embodiment. The energy converter 2 includes a buoy 38, upper and lower base plates 31, 32, two hydraulic cylinders 33, 34 installed on the upper and lower base plates 31, 32 and pistons 35, 36 matched with the hydraulic cylinders; the upper and lower base plates 31, 32 Connected and fixed by at least two fixed rods 37; the upper and lower ends of the buoy 38 are respectively provided with connecting rods 39, 40, which are respectively connected with the pistons 35, 36 of the two hydraulic cylinders 33, 34 installed on the upper and lower bottom plates 31, 32 facing each other The buoy 38 is movably connected with the fixed rod 37 through a linear bearing, and the buoy 38 can slide on the fixed rod 37; the oil inlet ends of the two hydraulic cylinders 33, 34 are equipped with a check valve 41, 42 respectively and are connected by an oil pipe 45 At th...

Embodiment 3

[0034] The device of the present invention can be installed in a water storage tank, and the device of the present invention includes a support, a rotating shaft, an energy converter and a hydraulic transmission mechanism, and is characterized in that: it is in an annular ring with the rotating shaft 6 installed on the support 4 as the axis At least three energy converters 2 are installed inside the frame 1 according to radial uniform distribution. The transmission mechanism is composed of a hydraulic cylinder 19, check valves 24, 25, oil pipes 26, 27, a hydraulic oil tank 11, a high-pressure oil accumulator 12 and a hydraulic actuator 5. The turning mechanism 3 is directly connected with the rotating shaft 6 and directly drives the rotating shaft. The energy converter 2 fixedly connected with the rotating shaft 6, the annular frame 1 concentric with the rotating shaft 6 and fixedly connected, the turning mechanism 3 and the support 4 are all below the water surface, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com