An Improved Pipeline Stainless Steel Lining Repair Method

A repair method, stainless steel technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of pipelines without stable anchorage, failure of lining pipes, influence of pipeline functions, etc., to improve negative pressure resistance and Capability of external water pressure, increased overall rigidity, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The present invention provides an improved pipeline stainless steel lining repair method. This method aims to provide a simple and feasible solution to the technical problems existing in the existing stainless steel lining repair, so as to give full play to the stainless steel lining. The advantage of lining repair is to enhance the ability of the lining pipe to resist negative pressure and external water pressure, thereby ensuring the quality and service life of the repaired pipeline.

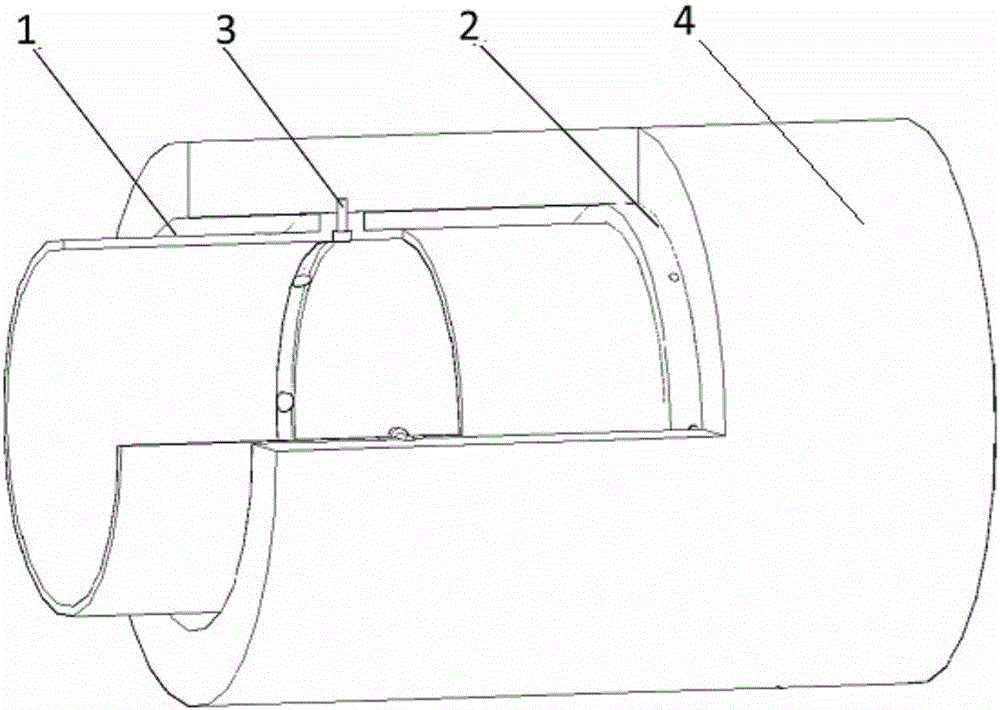

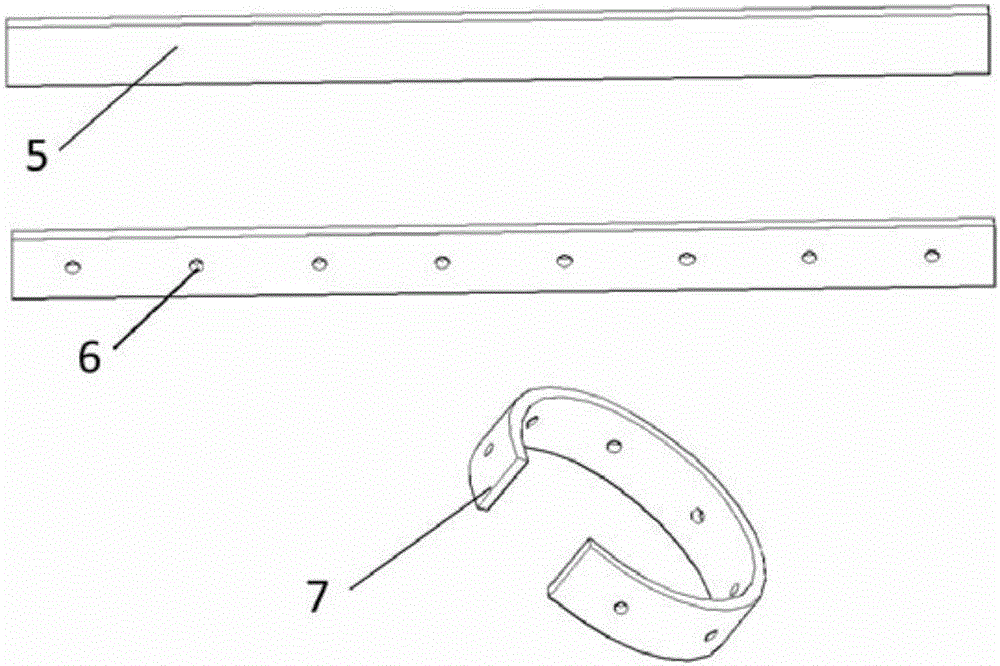

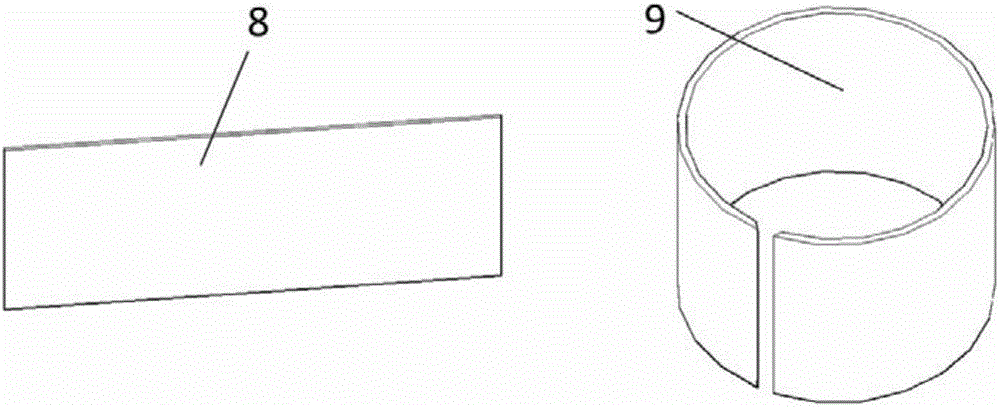

[0028] The present invention is an improved pipeline stainless steel lining repair method, the implementation process is as follows figure 1 , 2 , 3 shown. The implementation steps are as follows:

[0029] (1) According to the condition of the old pipeline 4, design a coupling 2 that meets the strength requirements. The coupling 2 is designed according to the cross-sectional shape and size of the old pipeline 4. The coupling 2 is made of stainless steel. The outer diamet...

Embodiment 2

[0035] Embodiment 2: An improved pipeline stainless steel lining repair method of the present invention is different from Embodiment 1 in that the diameter of the old pipeline 4 to be repaired is relatively large, so the coupling 2 is processed into two and a half pieces according to the diameter of the old pipeline 4 Circular combined splicing products; when in use, the two semicircular parts of the coupling are butted and welded together, and the coupling 2 is made of ordinary steel with anti-corrosion treatment. The filling slurry used in this embodiment is cement slurry. Other operating steps are the same as in Example 1.

[0036] The improved pipeline stainless steel lining repair method of the present invention is simple, and the repaired pipeline is safer in operation and has a more guaranteed service life, especially the repair of large-diameter pipelines is more cost-effective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com