Rotor for rotary electric machine

A technology for rotating electrical machines and rotors, applied in the field of rotors of rotating electrical machines, can solve the problems of short-circuiting of the permanent magnet 112, the strength of the rotor core 111 decreasing, and the damage of the rotor 110, etc. Effect of suppressing magnetic flux short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] Hereinafter, the rotor of the rotating electric machine according to each embodiment of the present invention will be described.

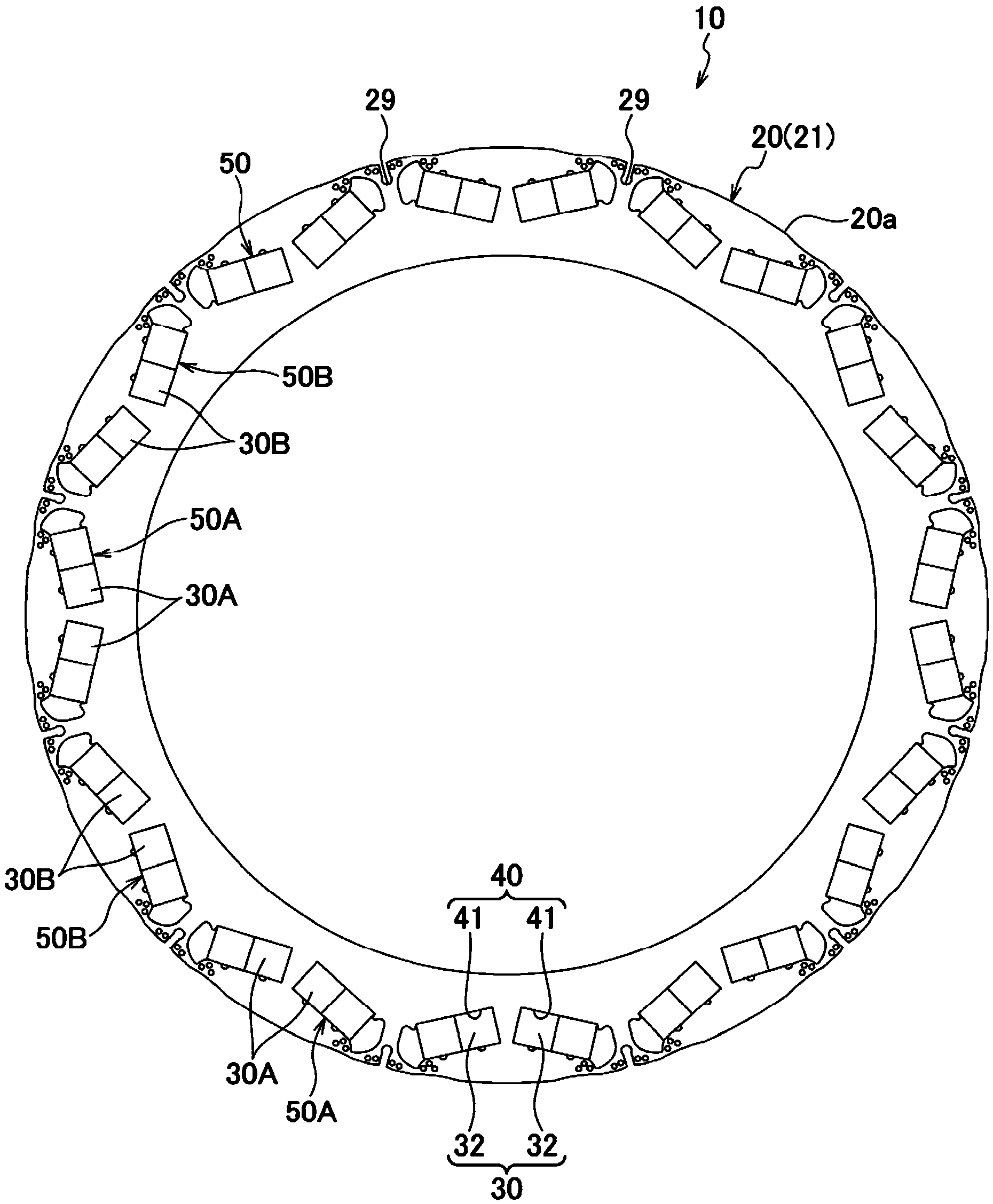

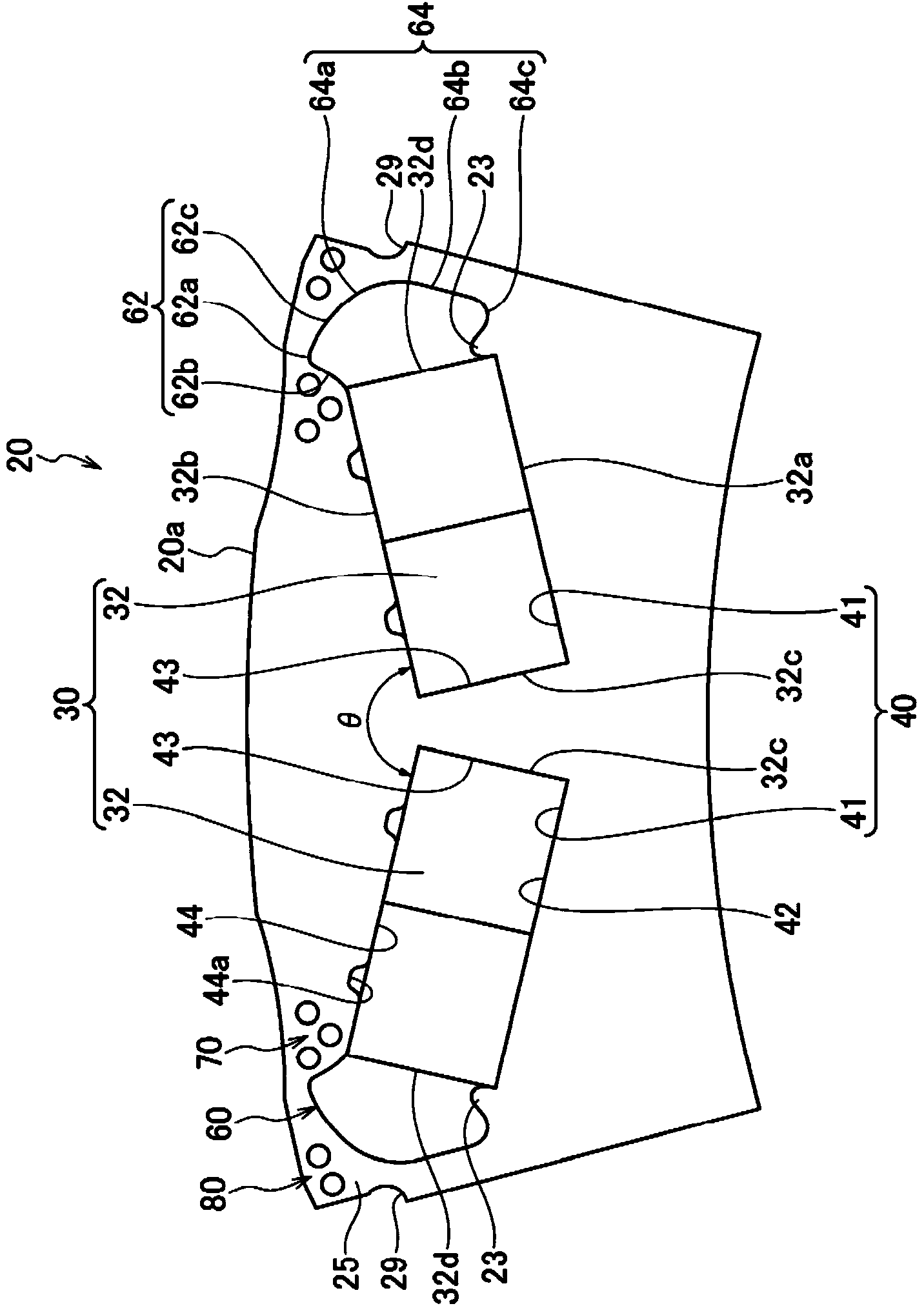

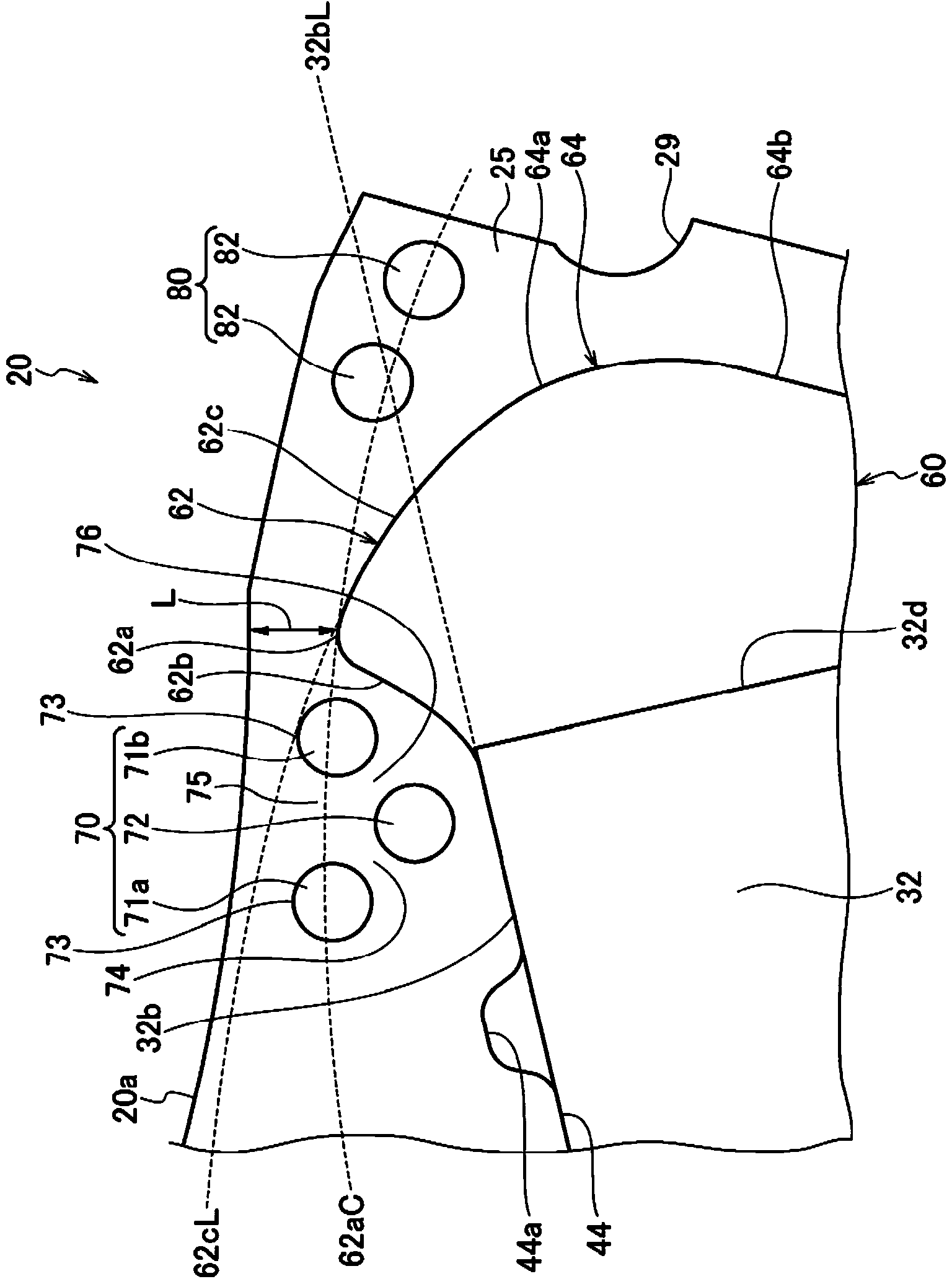

[0115] like figure 1 and figure 2 As shown, the rotor 10 of the rotating electrical machine according to the first embodiment includes a rotor core 20 and a plurality of magnetic pole portions 50, and is arranged on the inner peripheral side of a stator (not shown). On the outer peripheral side of a cylindrical rotor shaft (not shown), the plurality of magnetic pole portions 50 are formed at predetermined intervals in the circumferential direction inside the rotor core 20 .

[0116] The rotor core 20 is formed by laminating a plurality of annular electromagnetic steel sheets of approximately the same shape, such as silicon steel sheets 21, and a plurality of magnet insertion holes 40 are formed at predetermined intervals along the circumferential direction. A groove 29 is recessed between 40 .

[0117] The magnetic pole portion 50 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com