Electrical part, nonaqueous-electrolyte cell, and lead conductor with insulating coating layer and sealed vessel each for use in these

A non-aqueous electrolyte, wire conductor technology, applied in the field of electrical components, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

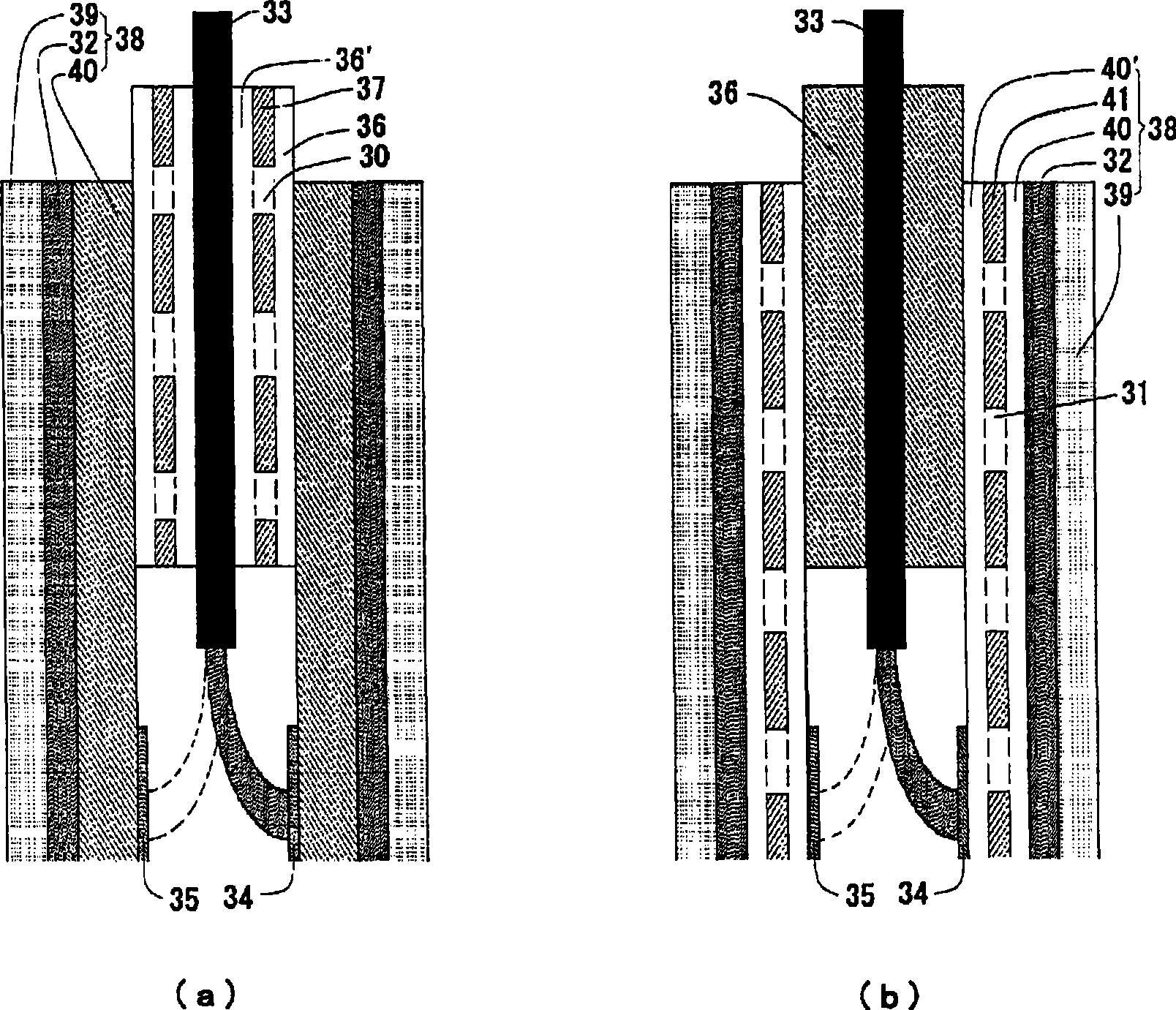

[0064] [Preparation of Wire Conductors with Insulation Coverings Used in Evaluation Tests]

[0065] (Preparation of wire conductors)

[0066] The wire conductor for the cathode was an aluminum plate with a thickness of 0.1 mm, a width of 5 mm and a length of 100 mm. The wire conductor for the anode was a copper plate with a thickness of 0.1 mm, a width of 5 mm and a length of 100 mm.

[0067] (Preparation of insulating cover layer)

[0068] The following four (a, b, c, d) insulating coatings were prepared and applied to the above-mentioned wire conductors, respectively.

[0069] Insulation covering a:

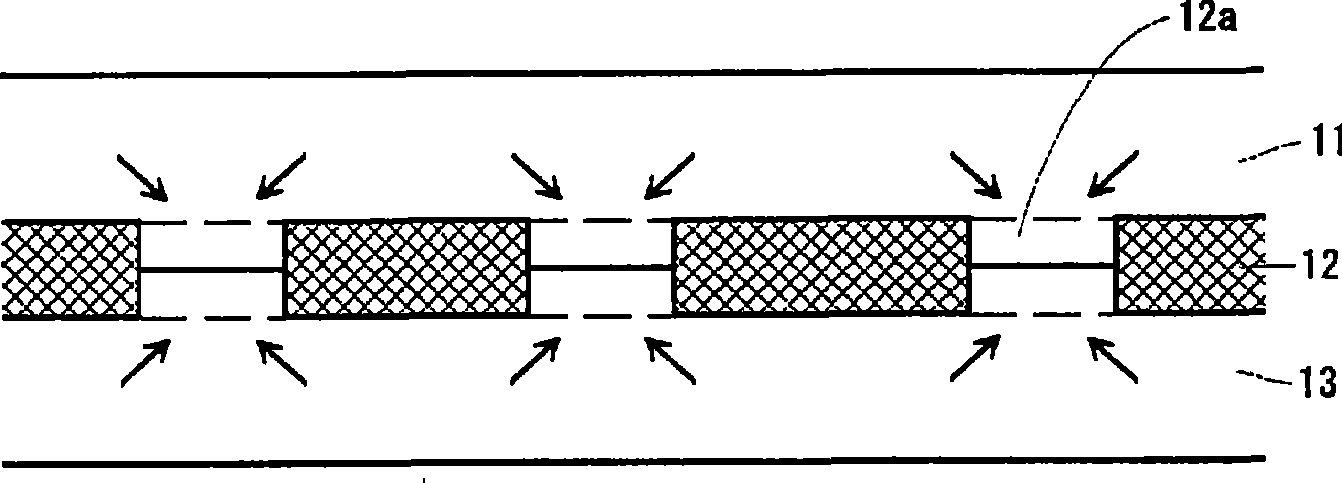

[0070]Overlap in the order listed below to prepare an insulating cover layer a: 50 μm thick maleic anhydride-modified polyethylene (thermal adhesive layer 1: AdmerNE060 produced by Mitsui Chemicals, Inc., density 0.92 g / cc, melt flow rate 1.0, softening temperature 104° C.), 25 μm thick polyester having through-holes prepared in the thickness direction, the through-holes ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com