Negative pole piece, preparation method thereof and electrochemical device

A negative electrode sheet and negative electrode technology, applied in the direction of electrochemical generators, negative electrodes, electrode manufacturing, etc., can solve the problems of increasing the irreversible capacity of electrochemical devices, deteriorating the safety performance of electrochemical devices, short-circuiting electrochemical devices, etc., achieving excellent Safety performance and cycle performance, improvement of kinetic performance, and effect of suppressing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The embodiment of the present invention also provides a method for preparing the negative electrode sheet 10, the method comprising the following steps:

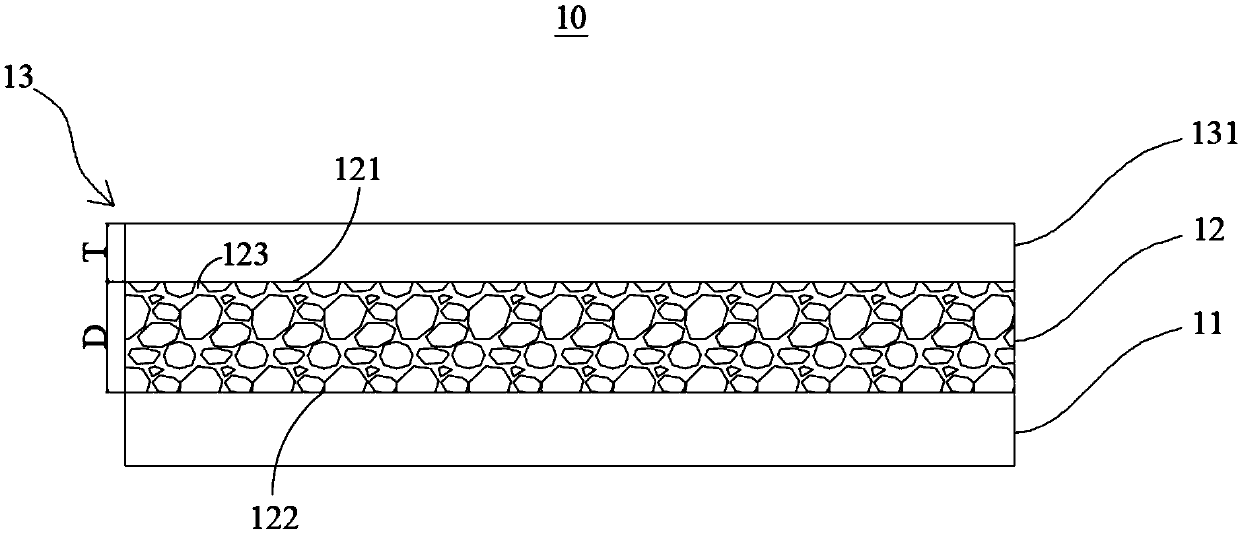

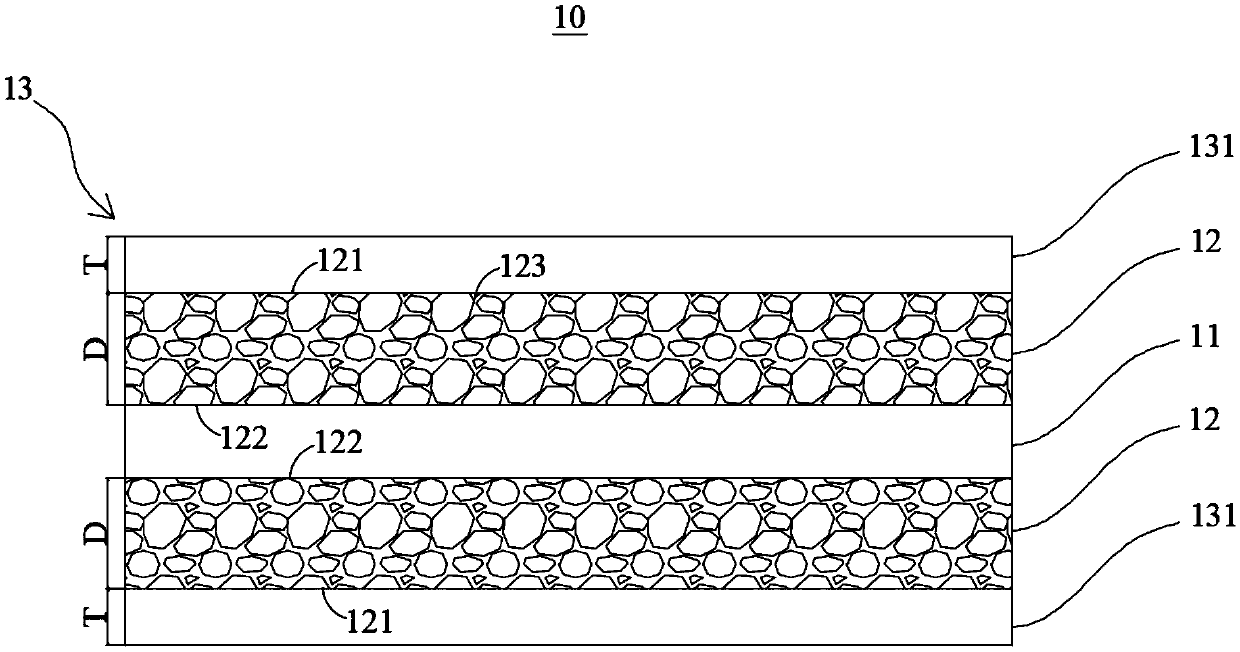

[0059] Step S100, disposing a negative electrode active material layer on at least one surface of the negative electrode current collector.

[0060] Step S100 can be implemented in any of the following ways:

[0061]Negative electrode active material and optional binding agent and conductive agent are dispersed in solvent, and solvent can be deionized water or N-methylpyrrolidone (NMP) for example, forms uniform negative electrode slurry; Negative electrode slurry is coated or It is sprayed on the surface of the negative electrode collector, and after drying and other processes, a negative electrode active material layer is prepared on at least one surface of the negative electrode collector.

[0062] The negative electrode active material is directly prepared on the negative electrode current collector to obtain a n...

Embodiment 1

[0107] Preparation of negative electrode sheet

[0108] Step S110, mix the negative electrode active material, the conductive agent acetylene black, the binder styrene-butadiene rubber (SBR), and the thickener sodium carboxymethylcellulose (CMC) according to the weight ratio of 96:1:2:1, and add a solvent to remove Ionized water, stirred and mixed evenly to obtain negative electrode slurry. Wherein the negative electrode active material is artificial graphite.

[0109] Step S120 , uniformly coating the negative electrode slurry on both surfaces of the negative electrode current collector copper foil, drying at 80° C. to 90° C. after coating, and then cold pressing to obtain a negative electrode active material coating.

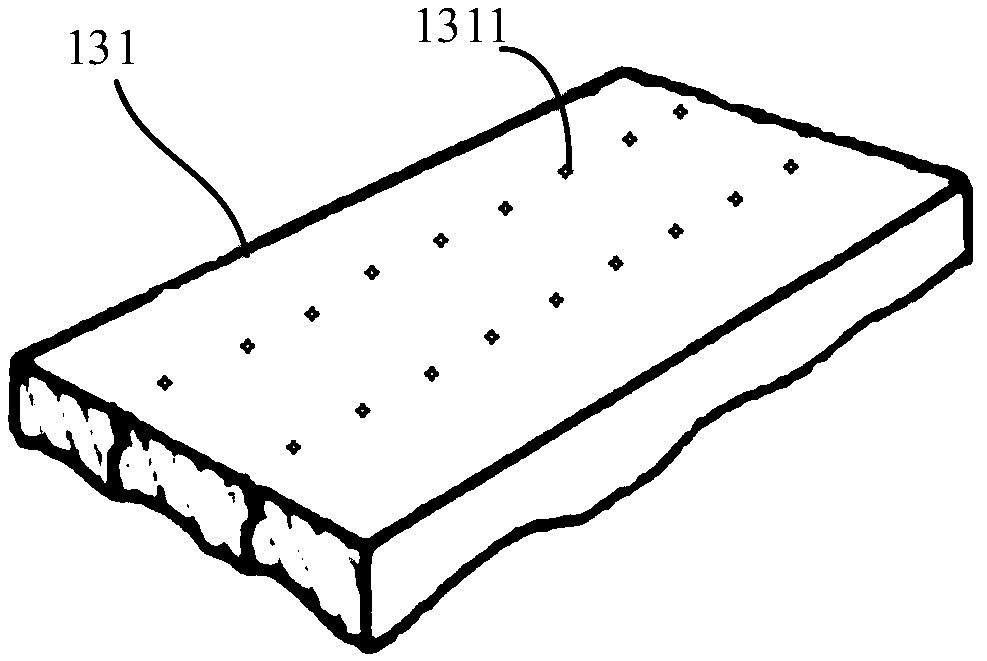

[0110] Step S200 , using a plasma-assisted electron beam evaporation method to prepare an inorganic dielectric layer on the surface of the negative electrode active material coating. Specifically include:

[0111] Step S210', vacuumize the reaction chambe...

Embodiment 2~7

[0122] The difference from Example 1 is that the relevant parameters in the preparation steps of the negative electrode sheet are adjusted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com