Rolling bearing unit with combination seal ring

一种组合密封、滚动轴承的技术,应用在滚动接触轴承、轴承元件、旋转运动的轴承等方向,能够解决部件件数增加、设置空间增加、旋转阻力增大等问题,达到良好密封性能、摩擦力抑制、旋转阻力的增大抑制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

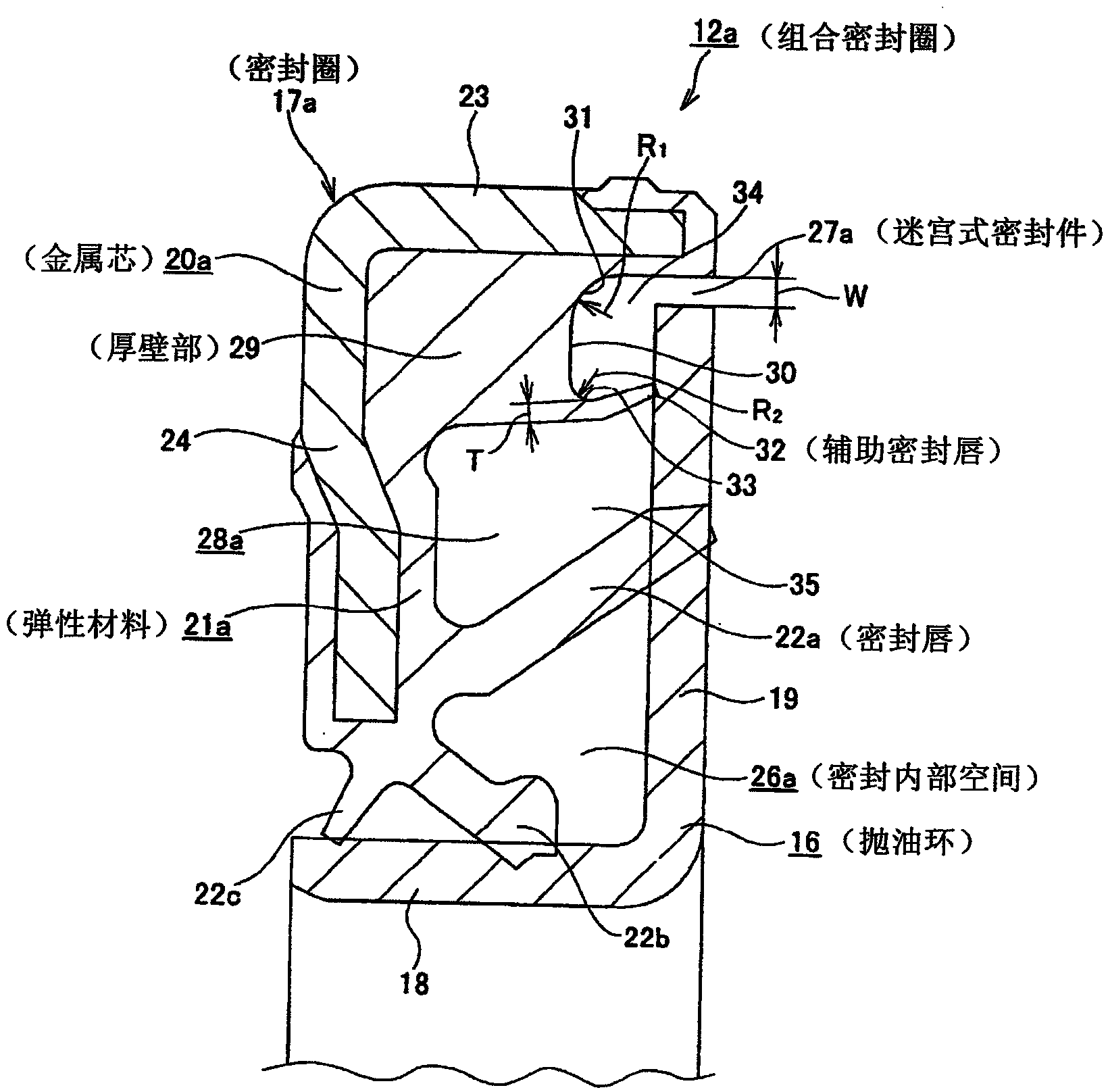

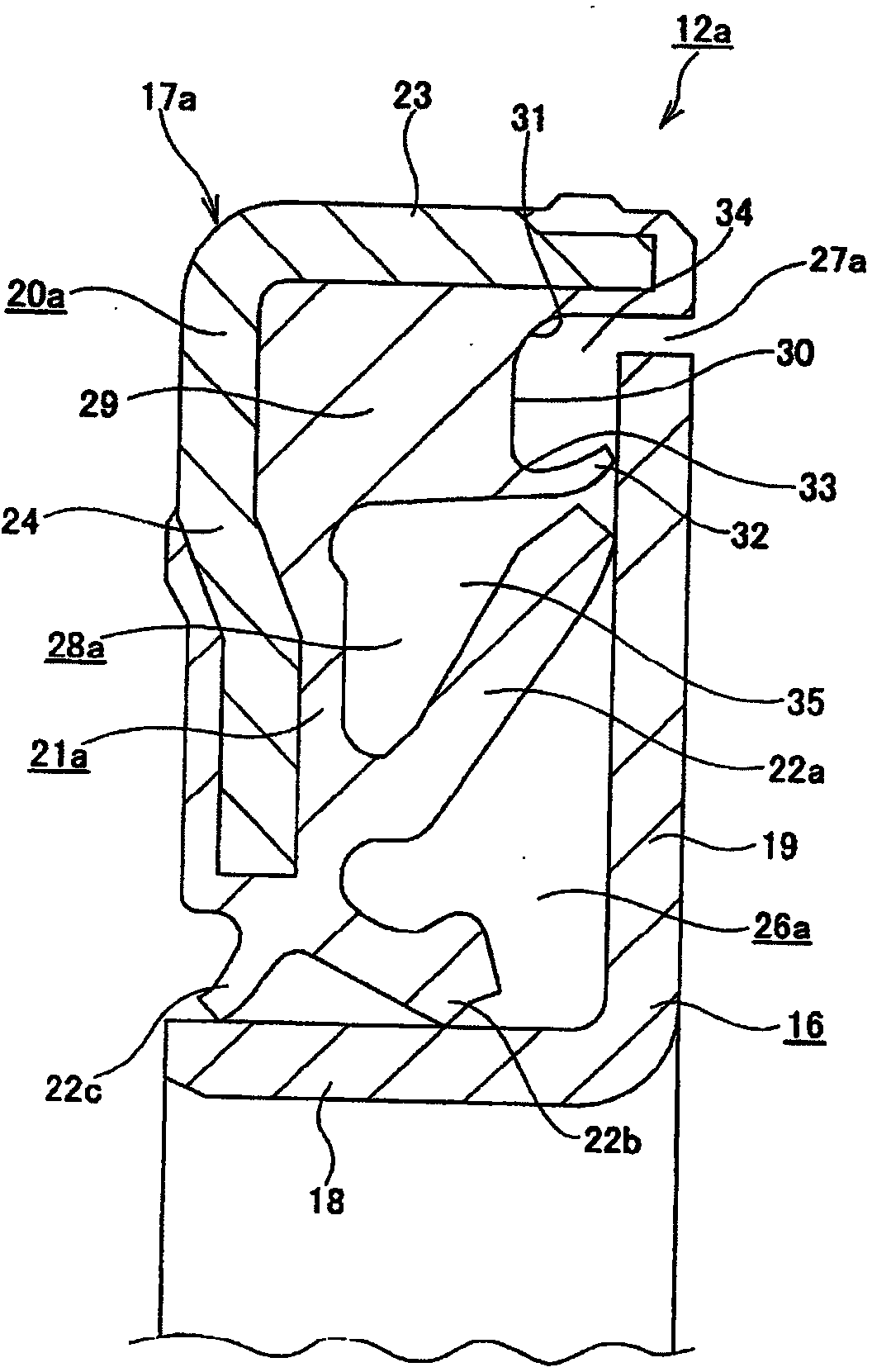

[0076] figure 1 The first embodiment of the present invention is shown. In addition, including the present embodiment, the rolling bearing unit with a combined seal ring according to the present invention is characterized in that, on the elastic material constituting the seal ring, in addition to the plurality of seal lips provided on the elastic material, there are also Auxiliary sealing lips with lower rigidity than the sealing lips are provided to prevent foreign matter from entering the sealed internal space of the combined sealing ring, and to prevent foreign matter from adhering to the outer space of the sealing lips, for long-term use. Keep the sealing performance of the combined sealing ring good. Regarding the composition and functions of other parts, including the aforementioned Figure 18 The rolling bearing unit 1 shown is the same as various conventionally known rolling bearing units, for example, in order to rotatably support the wheel with respect to the suspe...

no. 2 Embodiment approach

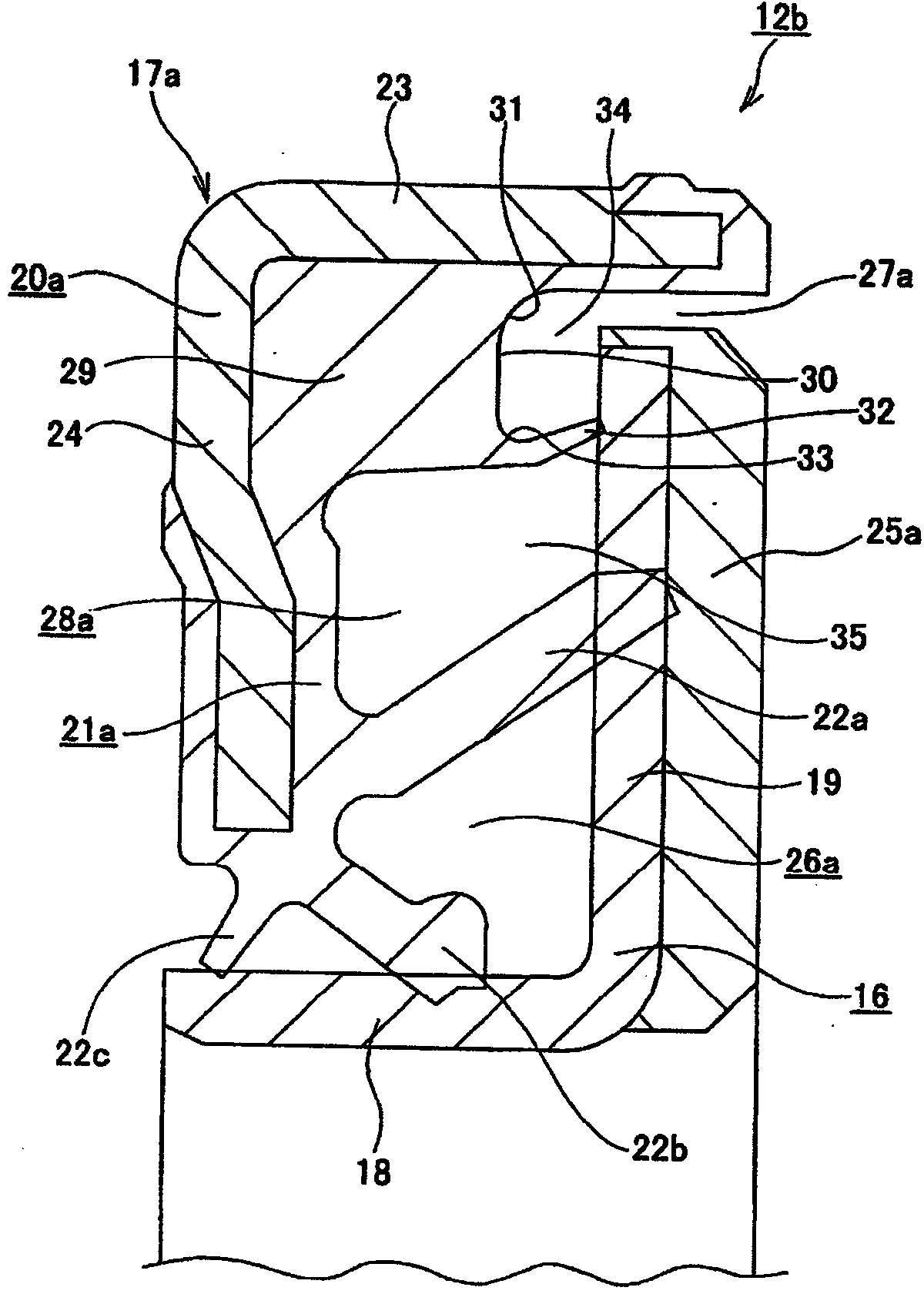

[0097] image 3 The second embodiment of the present invention is shown. In the case of the present embodiment, on the inner surface in the axial direction of the rotary side circular portion 19 constituting the oil slinger 16, magnetic powder dispersed in a polymer material such as rubber or synthetic resin is added along the entire circumference to form a circular shape as a whole. Encoder 25a made of permanent magnets. This encoder 25a is formed so as to cover the front end side peripheral edge (outer peripheral edge) of the above-mentioned rotary side circular portion 19, and is covered with the inner peripheral surface (on the inner peripheral surface) of the stationary side cylindrical portion 23 constituting the metal core 20a of the seal ring 17a. A part of the elastic material 21a) constitutes a labyrinth seal 27a. In addition, as the elastic body constituting the elastic material 21a of the packing 17a, a material containing a paraffin component and having good wat...

no. 3 Embodiment approach

[0101] Figure 4The third embodiment of the present invention is shown. Also in the case of this embodiment, an encoder 25b made of permanent magnets is added along the entire circumference on the axially inner surface of the rotary-side circular portion 19 constituting the slinger 16 . In the case of the present embodiment, a part of the polymer material constituting the encoder 25b is made to go over the outer peripheral edge of the rotating-side circular portion 19 toward the side of the stationary-side circular portion 24 constituting the metal core 20a of the sealing ring 17a. It protrudes along the entire circumference to form a ring-shaped protrusion 36 . The inner peripheral surface of the protrusion 36 is set as a partially conical inclined surface 37 inclined in a direction in which the inner diameter increases toward the front end edge (outer in the axial direction). In addition, a portion including the outer peripheral surface of the protrusion 36 and the inner p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com