Dry land hockey stick and manufacturing method of dry land hockey stick

A hockey stick and the technology of its manufacturing method, which are applied to rackets, sports accessories, etc., can solve the problems of poor sliding performance, poor ball control performance, and poor flexibility of the hitting plate, and achieve fast hitting speed, high hitting speed, and overall quality light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

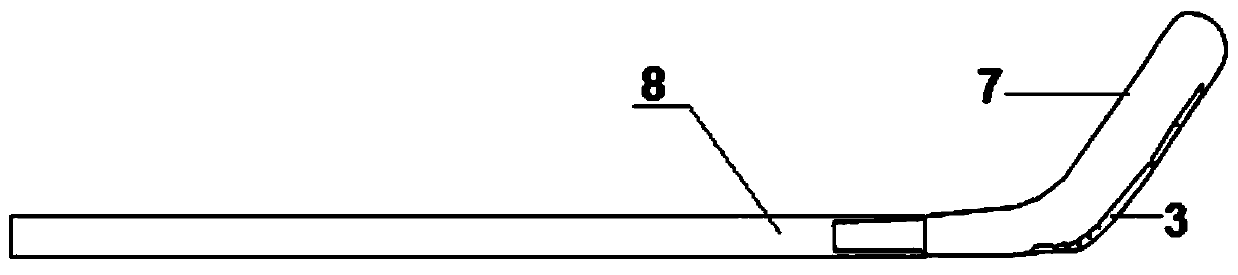

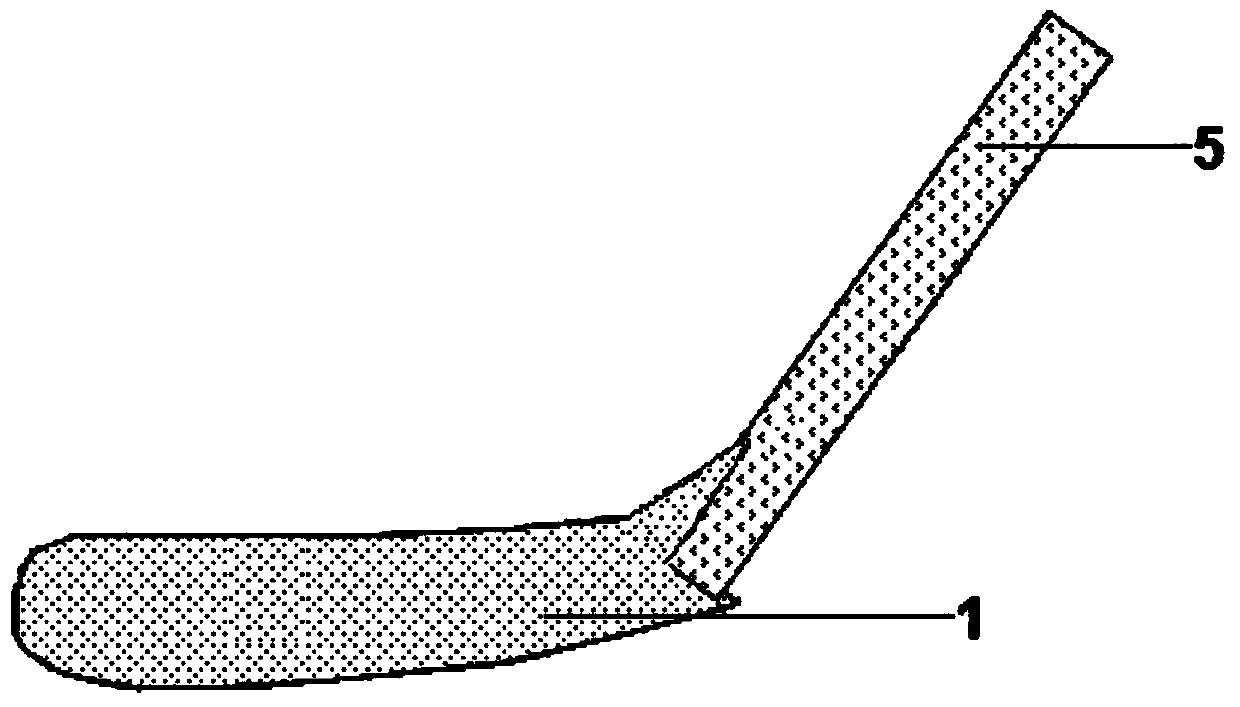

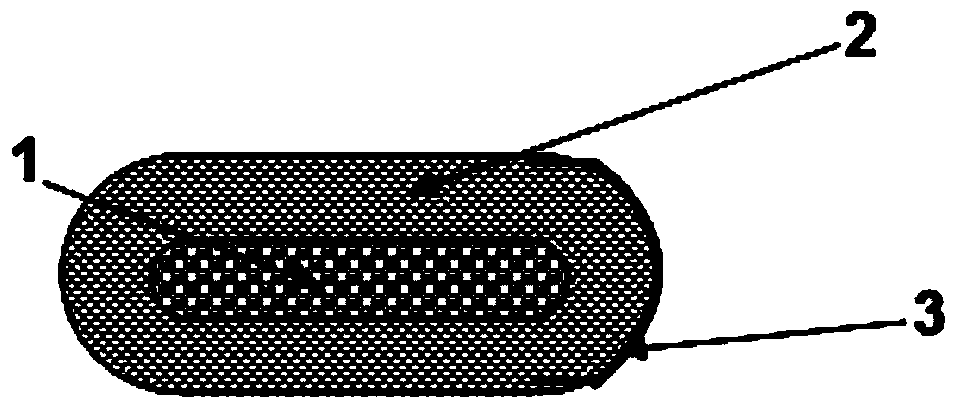

[0058] like figure 1 , image 3 The illustrated embodiment is a field hockey stick comprising a blade and a blade connected to the blade, a blade filler plate 1, a cover 2 disposed on the outside of the filler plate, and a cover 2 disposed on the cover. The wear-resistant structure 3 in the lower part of the layer, the cross-section of the wear-resistant structure is U-shaped with the opening upward, the upper part of the wear-resistant structure is embedded in the lower part of the cladding layer on both sides of the filling plate, and the lower part of the wear-resistant structure is located outside the lower edge of the cladding layer; The mill structure is made of ultra-high molecular weight polyethylene material.

[0059] The density of the filler board is 0.07g / cm 3 Made of PU epoxy resin foam material.

[0060] The height of the wear-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com