Perpendicular flow split conveying device for automatic tire production line

An automated production line, diverting conveying technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of inconvenient maintenance, unsafe and reliable use, low labor efficiency, etc., to achieve easy problem discovery and maintenance, simple structure and principle, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

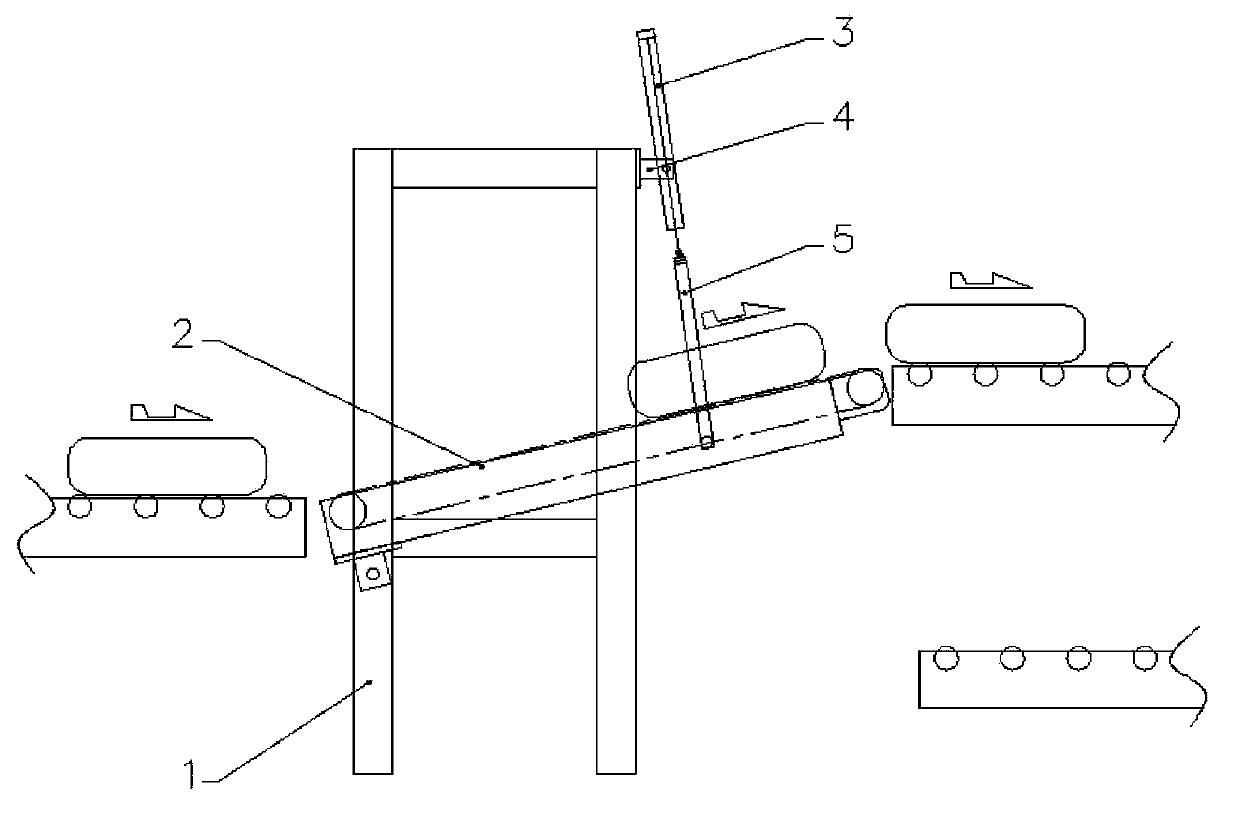

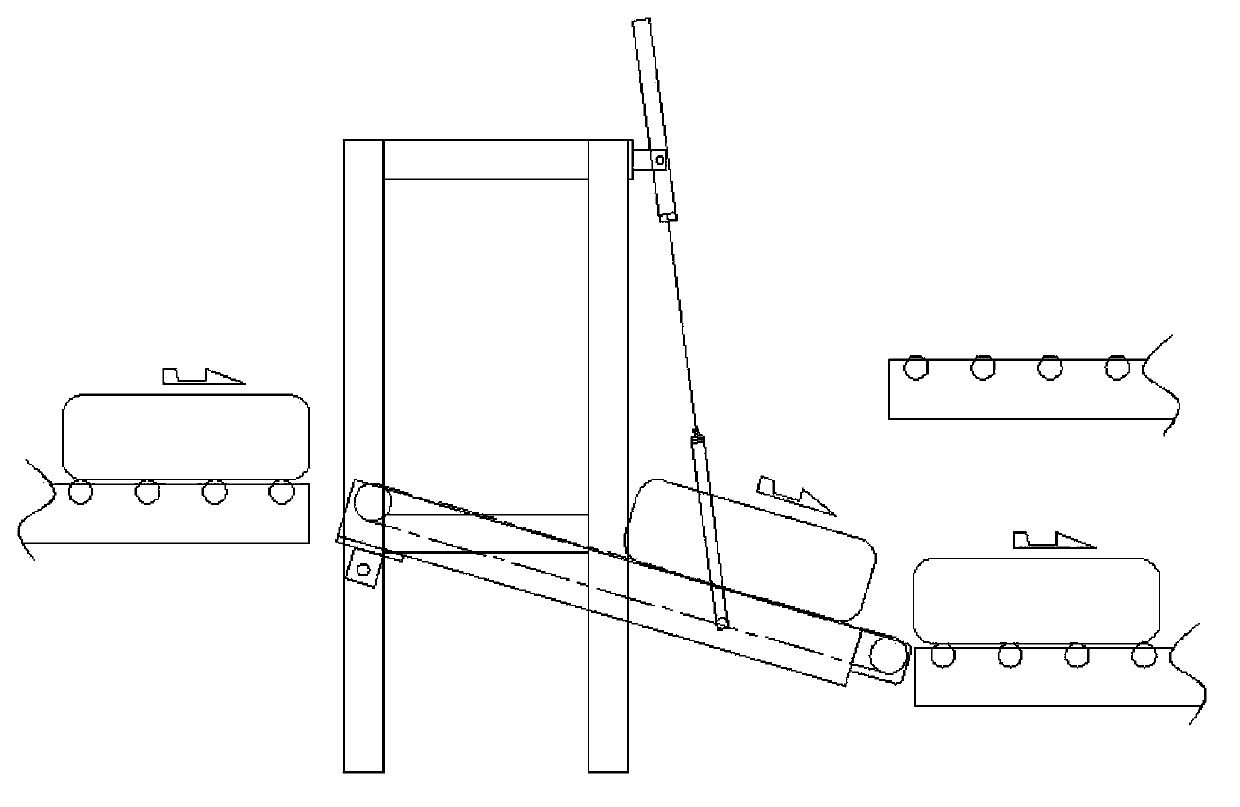

[0020] Such as figure 1 and 2 As shown, a vertical distribution conveying device for an automatic tire production line, including a frame 1, a belt conveyor 2, a cylinder 3 and a connecting rod 5, one end of the belt conveyor 2 is fixed on the frame 1, and the other end is passed through the connecting rod 5 is connected with the cylinder 3, and the cylinder 3 is fixed on the frame 1;

[0021] The cylinder 3 controls the rotation of the belt conveyor 2, and when the belt conveyor 2 reaches the specified position, the tires are directly delivered to the specified conveying line through the belt conveyor 2.

[0022] The cylinder 3 is fixed on the frame 1 through the cylinder fixing bracket 4 . The cylinder 3 is a hydraulic cylinder. The cylinder 3 controls the counterclockwise rotation of the belt conveyor 2, and the clockwise rotation of the belt conveyor 2 is controlled by the joint action of the dead weight and the cylinder 3. The input end of the belt conveyor 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com