Method and device for soaking corn by utilizing desulfurization water from power plant in starch production process

A production process, desulfurization water technology, applied in the biological field to achieve the effects of accelerating penetration, shortening soaking time, and increasing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

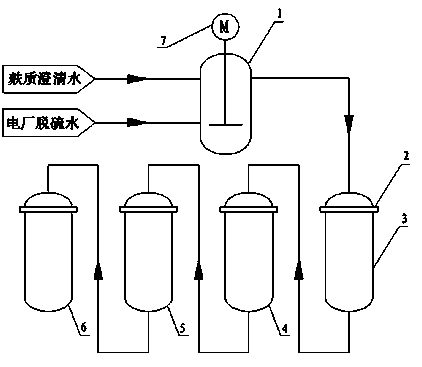

[0031] Example 1: Such as figure 1 Shown, utilize the method for soaking corn in the desulfurization water of power plant in the starch production process, the steps are as follows:

[0032] (1) Dilute the power plant desulfurization water containing 30% ammonium sulfite to a concentration of 0.12% with clarified gluten water;

[0033] (2) Add the soaking water that accounts for 2 / 5 of the total tank volume in four soaking tanks;

[0034] (3) In No. 1 soaking tank 3, the corn after the treatment is loaded into earlier, and the corn is 100 cm away from the top of the tank, and the soaking water is higher than the material layer 75 cm;

[0035] (4) Filling into No. 2, No. 3 and No. 4 soaking tanks successively every 3 hours, the method is the same as step (3);

[0036] (5) After the filling in No. 4 soaking tank 6 is completed, the power plant desulfurization water diluted in step (1) is continuously added to No. 1 soaking tank 3 by sprayer 2, and the temperature in No. 1 s...

Embodiment 2

[0042] Example 2: The method for soaking corn with desulfurized water from a power plant in the starch production process, the steps are as follows:

[0043] (1) Dilute the power plant desulfurization water containing 30% ammonium sulfite to a concentration of 0.18% with clarified gluten water;

[0044] (2) Add the soaking water that accounts for 1 / 2 of the total tank volume in four soaking tanks;

[0045] (3) In No. 1 soaking tank 3, the corn after the treatment is loaded into earlier, and the corn is 150cm apart from the tank top, and the soaking water is higher than the material layer 75cm;

[0046] (4) Filling in No. 2, No. 3 and No. 4 soaking tanks successively every 5 hours, the method is the same as step (3);

[0047] (5) After the filling in No. 4 soaking tank 6 is completed, the power plant desulfurization water diluted in step (1) is continuously added to No. 1 soaking tank 3 by sprayer 2, and the temperature in No. 1 soaking tank 3 is raised. to 55°C;

[0048] (6...

Embodiment 3

[0053] Example 3: The method for soaking corn with desulfurized water from a power plant in the starch production process, the steps are as follows:

[0054] (1) Dilute the power plant desulfurization water containing 30% ammonium sulfite to a concentration of 0.14% with clarified gluten water;

[0055] (2) Add the soaking water that accounts for 2 / 5 of the total tank volume in four soaking tanks;

[0056] (3) In No. 1 soaking tank 3, the corn after the treatment is loaded into earlier, and the corn is 125cm apart from the tank top, and the soaking water is higher than the material layer 75cm;

[0057] (4) Filling in No. 2, No. 3 and No. 4 soaking tanks successively every 4 hours, the method is the same as step (3);

[0058] (5) After the filling in No. 4 soaking tank 6 is completed, the power plant desulfurization water diluted in step (1) is continuously added to No. 1 soaking tank 3 by sprayer 2, and the temperature in No. 1 soaking tank 3 is raised. to 52°C;

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com