A glass-ceramic facing lightweight ceramic composite brick and its preparation method

A technology of glass-ceramics and lightweight ceramics, which is applied in the direction of ceramic layered products, chemical instruments and methods, glass/slag layered products, etc., which can solve the problems of low stability, difficulty in base layer thickness, and decreased wear resistance, etc. problems, to achieve the effects of energy saving and environmental protection in the production process, promoting sustainable development, and excellent decorative performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

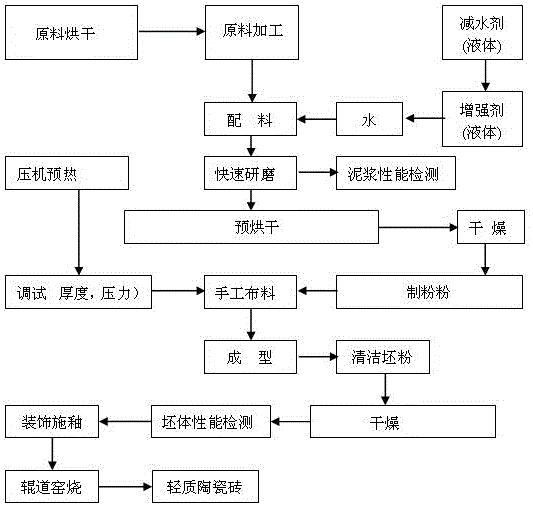

[0036] The preparation method of the described glass-ceramic facing lightweight ceramic composite brick, the specific steps are:

[0037] a. Raw material preparation: dry the raw material at a temperature of 105°C-120°C, and pass through a 20-mesh sieve;

[0038] b. Batching ball milling: batching the dried and sieved raw materials, and adding water reducing agent, strengthening agent and water respectively, and putting them into a wet ball mill for ball milling;

[0039] c. Spray drying: Send the raw materials that have been milled by a ball mill into a spray drying tower for drying. The moisture content is within 9.0-10.0. After drying, the silo is closed and stale. After dry mixing and fading, pass through a 20-80 mesh sieve for granulation;

[0040] d. Cloth forming: After the powder obtained in step c is formed by secondary cloth reverse blowing, the green body is cleaned and dried after the green powder is cleaned, the performance of the green body is tested, and the glaze...

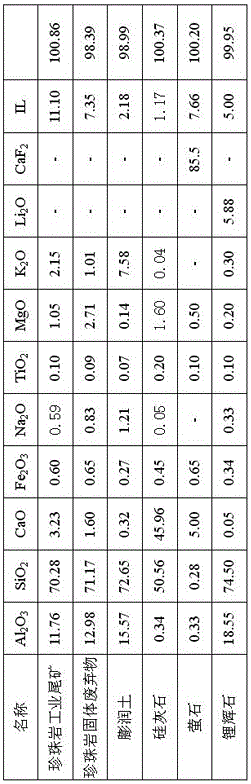

Embodiment 1

[0045] With the perlite tailings sand of 55 parts by weight, the perlite fine powder of 25 parts by weight, the bentonite of 20 parts by weight, and the sodium metapolyphosphate of 0.2 parts by weight, the sodium humate of 0.1 part by weight, the green silicon carbide of 0.5 parts by weight Put the micropowder and the closed-cell foam ceramic matrix formula of 85 parts by weight of water into the wet ball mill, and ball mill until the mud fineness is 2.30-2.50% (residue of 10,000-hole sieve), the mud flow rate is controlled at 30-50 seconds, and the specific gravity is controlled at 1.50 ~1.60. And through the spray drying tower spraying high, the moisture is within 9.0-10.0, the powder within the particle size of 20-80 mesh, and the closed silo is stale for 24 hours for use. Similarly, 47 parts of perlite tailings, 40 parts of perlite powder by weight, 10 parts of bentonite by weight, 2 parts of wollastonite by weight, 0.5 parts of spodumene by weight, 0.5 parts of fluorite b...

Embodiment 2

[0047] 70 parts by weight of perlite tailings sand, 20 parts by weight of perlite micropowder, 10 parts by weight of bentonite, plus 0.2 parts by weight of sodium metapolyphosphate, 0.1 part by weight of sodium humate, and 0.3 parts by weight of green silicon carbide The closed-cell foam ceramic matrix formula of fine powder and 85 parts by weight of water is placed in a wet ball mill, and the ball mills until the mud fineness is 2.30% to 2.50% (the remainder of the 10,000-hole sieve), the mud flow rate is controlled at 30 to 50 seconds, and the specific gravity is controlled at Between 1.50 and 1.60. And through the high spraying of the spray drying tower, the moisture is within 9.0% ~ 10.0%, the powder within the particle size of 20-80 mesh, and the closed silo is stale for 24 hours for use; similarly, 16 parts of perlite tailings sand, weight 40 parts perlite micropowder, 20 parts by weight of bentonite, 22 parts by weight of wollastonite, 0.5 parts by weight of spodumene, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com