Dual-sound-wave eddy wax-preventing and viscosity-reducing device

A technology of eddy current and sound wave, which is applied in the field of dual-sonic eddy current anti-wax viscosity reducer, can solve the problems of not being able to adapt to oil wells, etc., and achieve the effect of increasing the effect of wax anti-wax and viscosity reduction, wide application range and long product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

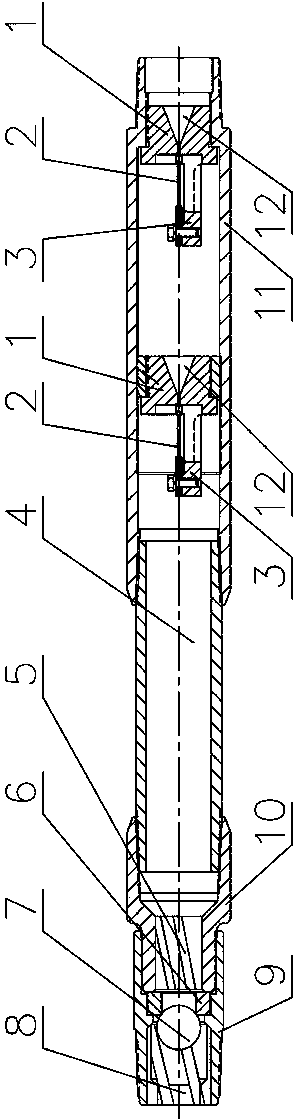

[0030] see figure 1 , the present invention is made up of jet ultrasonic oscillation part and vortex injector two parts, through a cavitation chamber 4 transition docking, cavitation chamber 4 of the present invention adopts a double-head external thread pipe joint to make, and cavitation chamber 4 can also be It is formed by extending the tubular casing 12 of the jet ultrasonic oscillator or extending the joint part of the guide section 10 of the vortex guide injector. Wherein: the jet ultrasonic oscillation part in the present invention has a steel cylindrical shell 11, and the first-stage jet oscillator and the second-stage jet oscillator are housed in the shell 11, and the distance between the two stages is arranged at a distance of 200 ± 50mm. The jet ultrasonic oscillator includes a plug-shaped jet head 1 that is threadedly connected to the housing 11. The jet head 1 is provided with a wedge-shaped through hole 12. The small mouth end is also designed with a small sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com