A biodegradable high-barrier composite film and its preparation method

A biodegradable and biodegradable material technology is applied in the preparation of the membrane and in the field of biodegradable high-barrier composite membranes, which can solve the problems of poor biodegradability, low mechanical properties and high cost, achieve easy dispersion and improve glass transition Temperature, the effect of improving barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

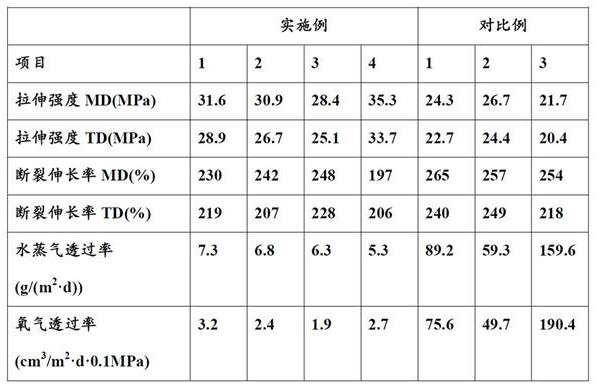

Examples

Synthetic example 1

[0049] Synthesis Example 1: Preparation of furandicarboxylic acid-succinic acid-isosorbide copolyester 1

[0050] Add 1 mol of 2,5-furandicarboxylic acid, 1 mol of 1,4-succinic acid and 2 mol of isosorbide into the reactor, exchange with nitrogen to remove air, then add 3 mmol of antimony trioxide as a catalyst, and heat to 200 under stirring. ℃ reacted for 1 hour, then heated to 220 ℃ and continued to react for 2 hours; then, the system pressure was reduced to below 50Pa by a vacuum pump, and further heated to 245 ℃ and reacted for another 1 hour. Furandicarboxylic acid-succinic acid-isosorbide copolyester 1 was obtained; IR spectrum showed it included 1725 cm -1 The polyester carbonyl absorption peak, 1022cm -1 The C-O absorption peak of the secondary hydroxyl group in isosorbide at ; 1 The conversion rate of isosorbide calculated from the characteristic peaks of different units in H NMR was 98.6%, and the number-average molecular weight measured by GPC gel chromatography ...

Synthetic example 2

[0051] Synthesis Example 2: Preparation of furandicarboxylic acid-succinic acid-isosorbide copolyester 2

[0052] Add 1.5 mol of 2,5-furandicarboxylic acid, 0.5 mol of 1,4-succinic acid and 2 mol of isosorbide to the reactor, exchange with nitrogen to remove air, then add 3 mmol of catalyst ethylene glycol antimony, and heat under stirring The reaction was carried out at 200°C for 1 hour, then the temperature was raised to 220°C and the reaction was continued for 2 hours; then, the system pressure was reduced to below 50Pa by a vacuum pump, and the temperature was further raised to 245°C for another 1 hour of reaction. furandicarboxylic acid-succinic acid-isosorbide copolyester 2 is obtained; 1 The conversion rate of isosorbide calculated by the characteristic peaks of different units in H NMR was 99.4%, and the number-average molecular weight measured by GPC gel chromatography was 11.2×10 4 Da, the molecular weight distribution was 2.2. According to ISO 14855, the copolyes...

Embodiment 1

[0054] 65 parts of furandicarboxylic acid-succinic acid-isosorbide copolyester of Synthesis Example 1, 25 parts of polypropylene carbonate (the number average molecular weight is 7.5×10 4 Da, molecular weight distribution is 2.0), 5 parts of triacetin, 10 parts of montmorillonite, 1 part of silane coupling agent KH560, 1 part of oleic acid amide were added to a high-speed mixer and mixed well, and then placed in an oven at 80 °C Dry for 5 hours, and then put it into a twin-screw extruder with an aspect ratio of 50:1 for extrusion granulation, the barrel temperature is 160 °C, and the die temperature is 170 °C; Extrusion blow molding is performed in a 35:1 single-screw extruder. There are six heating zones in the single-screw extruder from the inlet to the outlet: the first zone is 125°C; the second zone is 130°C; the third zone is 140°C; Four zones 150°C; five zones 160°C; six zones 165°C; head temperature 160°C, screw speed 250rpm, traction speed 10m / min, and inflation ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com