Experimental device and method for simulating shale gas-pressure pressing crack process

A kind of experimental device and shale technology, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problem of inability to simply transplant or adjust the shale gas pressure fracturing experiment device, the inability to accurately evaluate the fracturing effect, and the inability to Realize the search for fracturing gas and other problems, and achieve the effect of waste gas recovery, fracturing and crack expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

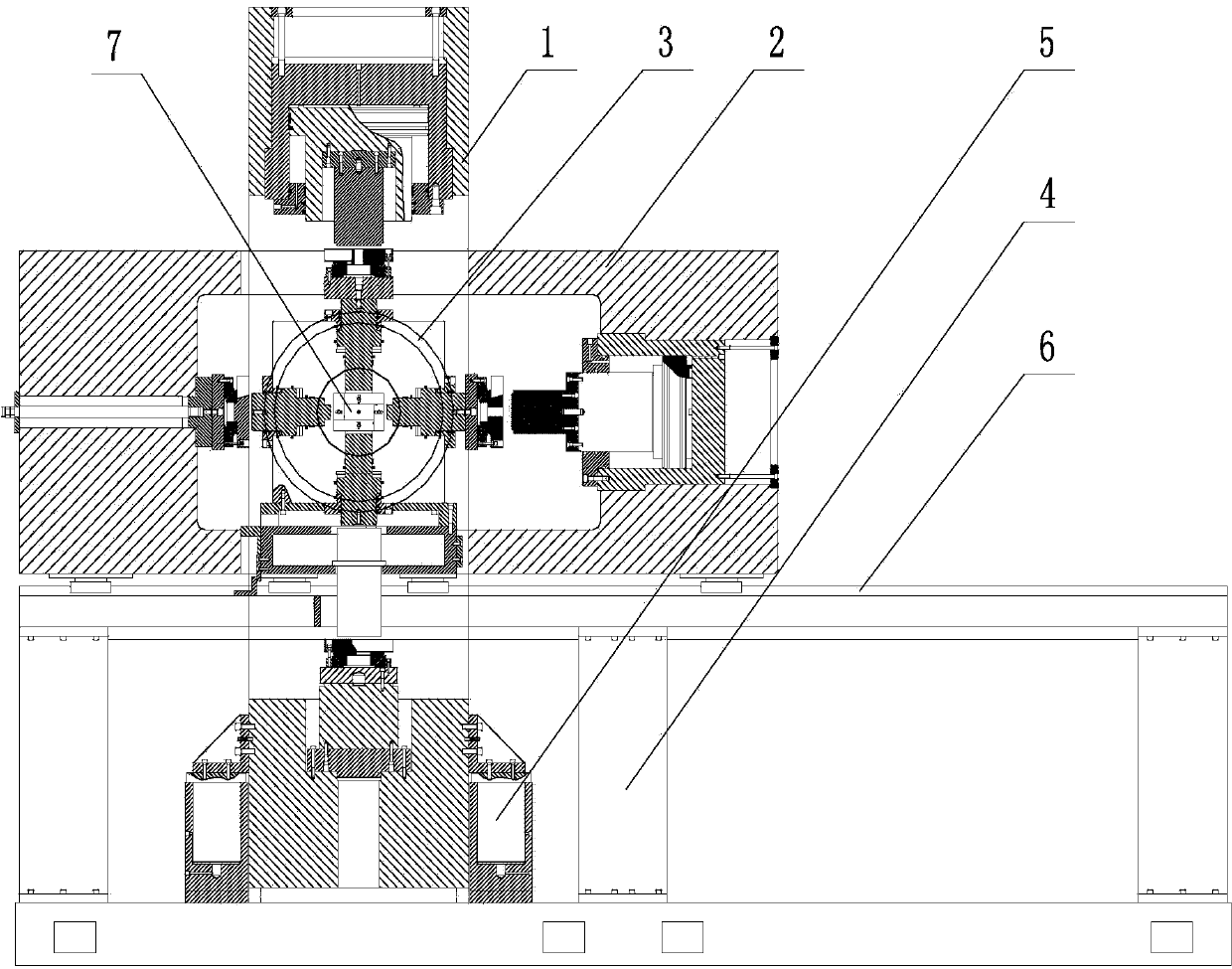

[0029] like figure 1 , 2 As shown, an experimental device for simulating the shale gas fracturing process includes a true triaxial loading unit and a gas fracturing system unit. The true triaxial loading unit includes a vertical loading frame 1, a horizontal loading frame 2, and a pressure chamber 3 and the support platform 4, the vertical loading frame 1 is installed on the support platform 4 through the support cylinder 5, the horizontal loading frame 2 is arranged on the support platform 4 through the sliding guide rail 6, the vertical loading frame 1 and the horizontal loading frame The two phases are orthogonal, the pressure chamber 3 is set in the horizontal loading frame 2, and the shale sample 7 is located in the pressure chamber 3;

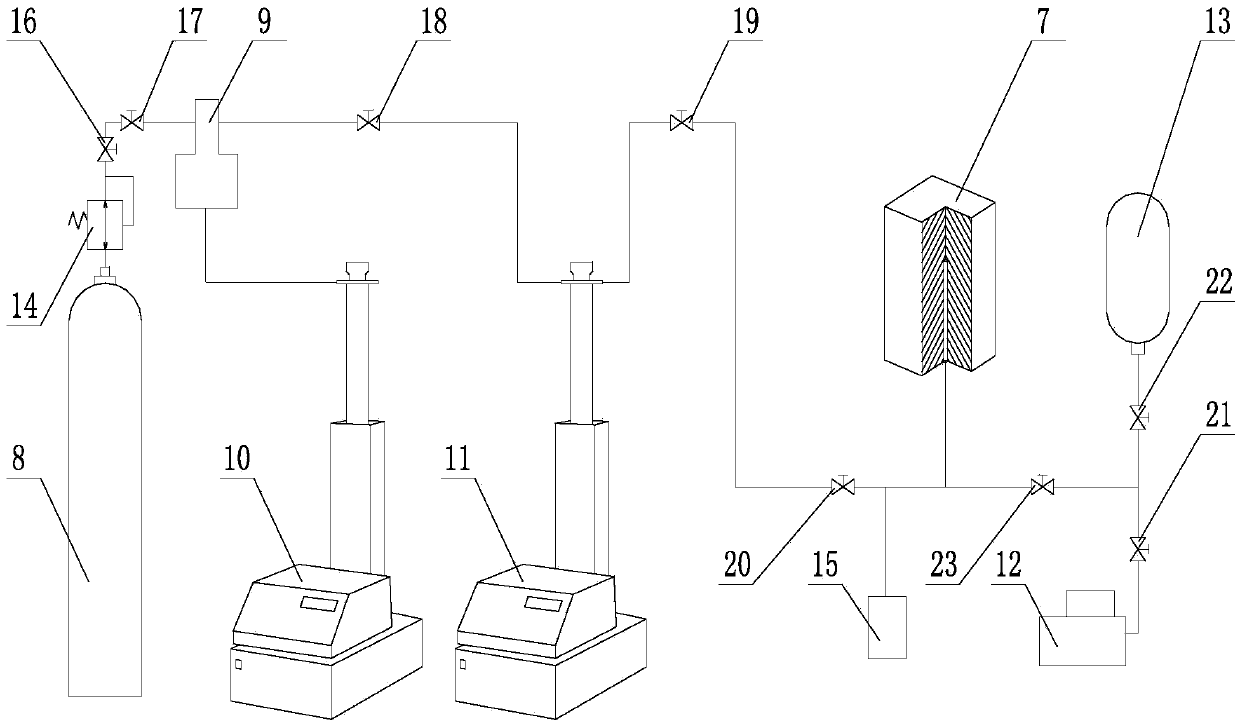

[0030] The air pressure fracturing system unit includes a high-pressure gas cylinder 8, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com