Compressor

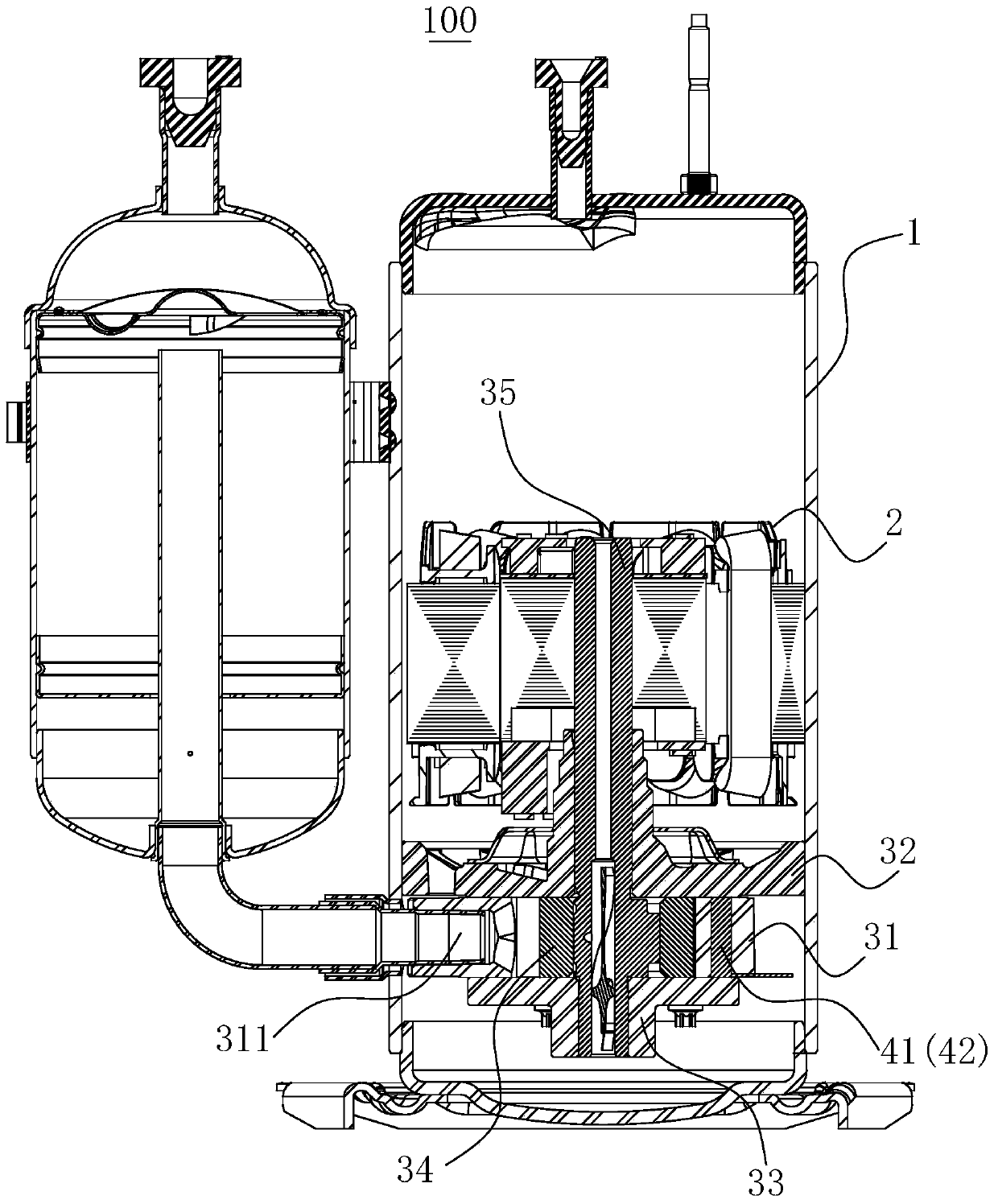

A compressor and compression mechanism technology, applied in the field of compressors, can solve problems such as overheating of the suction side of the cylinder, affecting the cooling capacity and power of the compressor, and difficulty in dissipating heat from the exhaust side, so as to reduce superheat and improve energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

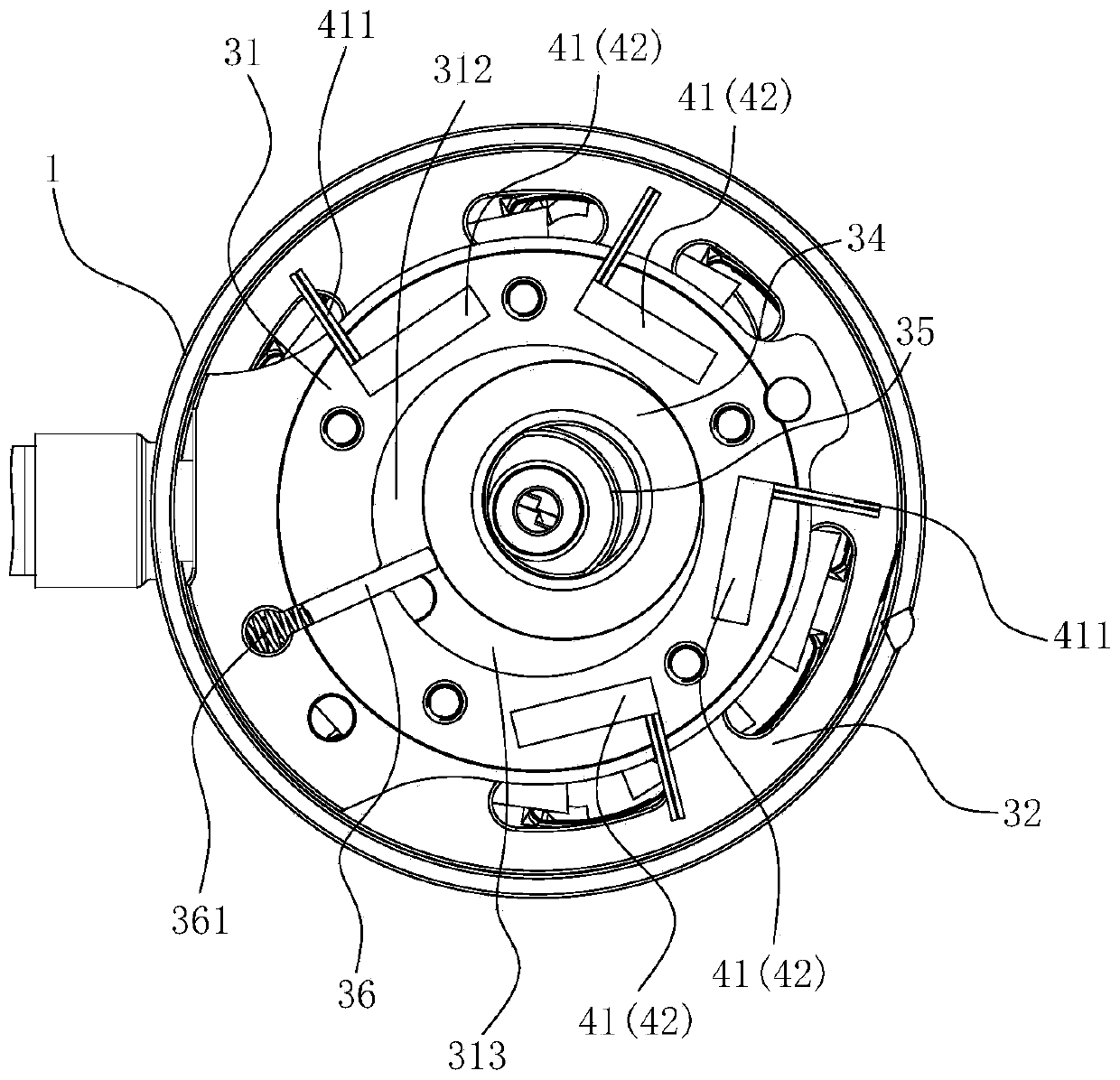

[0056] Such as figure 2 As shown, in this embodiment, the cylinder 31 is provided with four thermoelectric power generation components 41 or thermoelectric refrigeration components 42, two of which are located on the suction side of the cylinder 31 and arranged at intervals along the circumference of the cylinder 31, and the other two One is located on the exhaust side of the cylinder 31 and is also spaced apart from each other along the circumferential direction of the cylinder 31 .

[0057] Among them, these four can all be thermoelectric power generation components 41 , or all can be thermoelectric cooling components 42 , or one, two or three of them can be thermoelectric power generation components 41 , and the rest can be thermoelectric cooling components 42 .

Embodiment 2

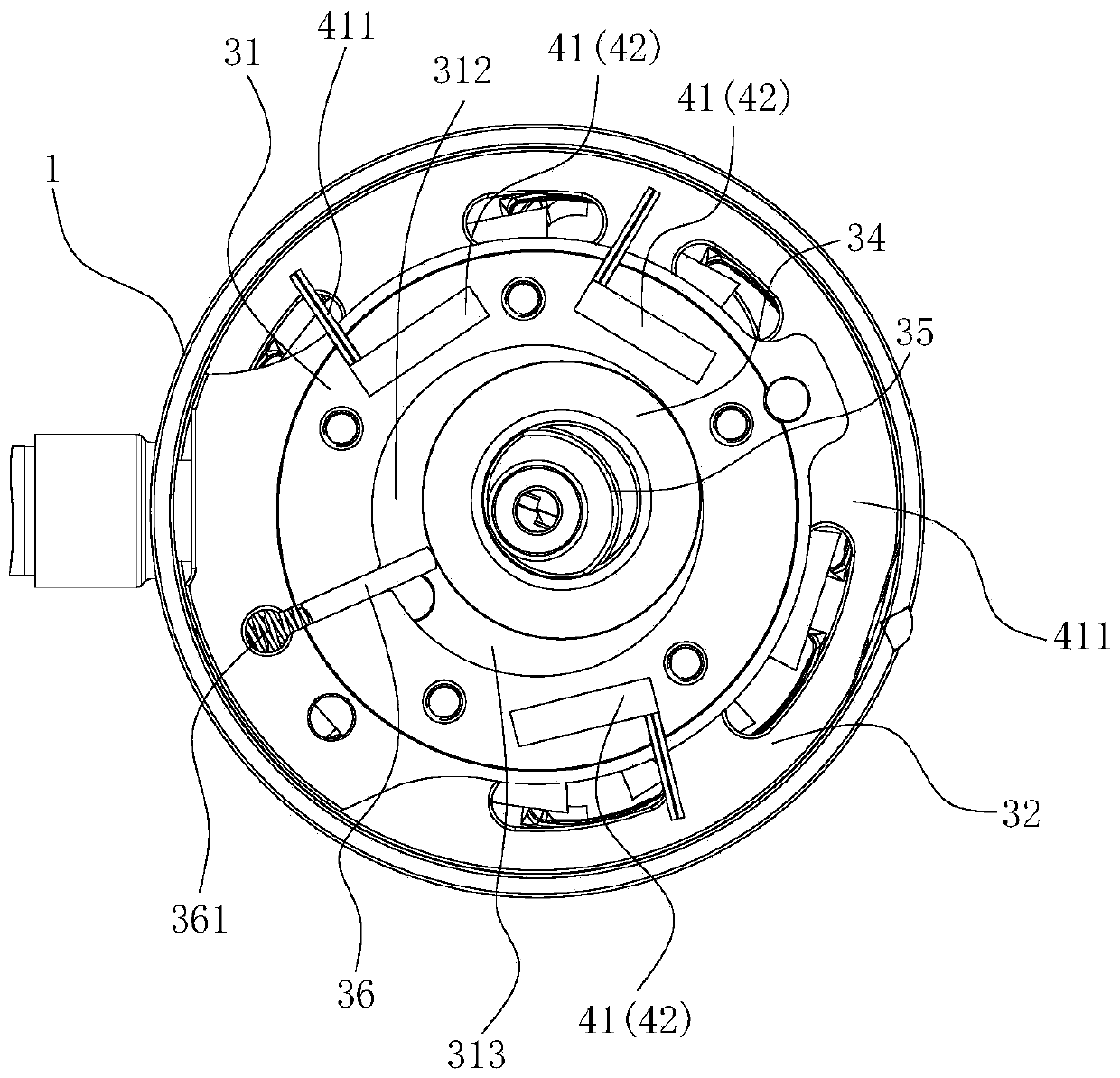

[0059] Such as image 3 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, and the only difference lies in the number of thermoelectric power generation assemblies 41 or thermoelectric cooling assemblies 42 on the exhaust side of the cylinder 31 different.

[0060] refer to image 3 A total of three thermoelectric power generation assemblies 41 or thermoelectric refrigeration assemblies 42 are provided on the cylinder 31 , two of which are located on the suction side of the cylinder 31 and arranged at intervals along the circumference of the cylinder 31 , and the other is located on the exhaust side of the cylinder 31 .

[0061] Wherein, these three can all be thermoelectric power generation components 41 , or all can be thermoelectric cooling components 42 , or one or two of them can be thermoelectric power generation components 41 , and the rest can be thermoelectric cool...

Embodiment 3

[0063] Such as Figure 4 As shown, the structure of the present embodiment is substantially the same as that of the second embodiment, wherein the same components are marked with the same reference numerals, and the only difference is that no thermoelectric power generation assembly 41 or thermoelectric cooling assembly 42 is provided on the exhaust side of the cylinder 31 .

[0064] refer to Figure 4 , the cylinder 31 is provided with two thermoelectric power generation components 41 or thermoelectric refrigeration components 42 , both of which are located on the suction side of the cylinder 31 and are spaced apart from each other along the circumferential direction of the cylinder 31 .

[0065] Wherein, these two can both be the thermoelectric power generation component 41 , or both can be the thermoelectric cooling component 42 , or one of them can be the thermoelectric power generation component 41 and the other can be the thermoelectric cooling component 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com