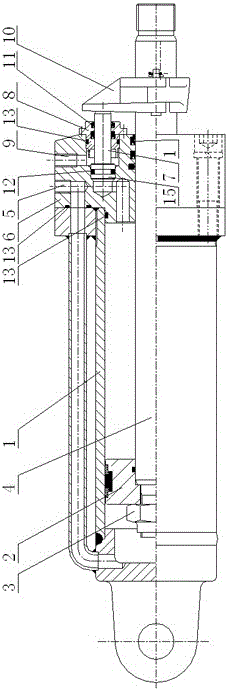

Full-stroke adjustable oil cylinder with built-in stop valve

A shut-off valve, full-stroke technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of high production cost, inability to adjust the full stroke, increase the overall length of the cylinder, etc., to save raw materials, convenient and accurate adjustment, and save additional devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment: the built-in shut-off valve full-stroke adjustable oil cylinder of this example, such as figure 1 , including a cylinder body 1, a piston 2 is arranged in the cylinder body, a piston rod 4 is connected to the piston through a lock nut 3, an oil inlet passage 5 is opened on the cylinder body to communicate with the oil cavity in the oil cylinder, and a guide sleeve is connected to one end of the cylinder body 6. A static seal 13 is provided on the inner end surface of the guide sleeve, and a piston rod seal and dustproof assembly 14 is provided on the inner circle of the guide sleeve. A shut-off valve stem 7 is arranged in the guide sleeve, and a shut-off valve spool 15 is provided at the inner end of the shut-off valve stem. The spool of the shut-off valve is connected in the guide sleeve. The outer end of the stop valve stem is connected in the stop valve end cover 8, the valve stem seal dustproof ring 11 is installed in the hole of the stop valve end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com