Connector of assembling frame and assembling frame formed by means of connector

A technology for assembling frames and skeletons, which is applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of three-way joint stress concentration, easy to break and damage assembly, time-consuming assembly, etc., achieve good strength, improve stability, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

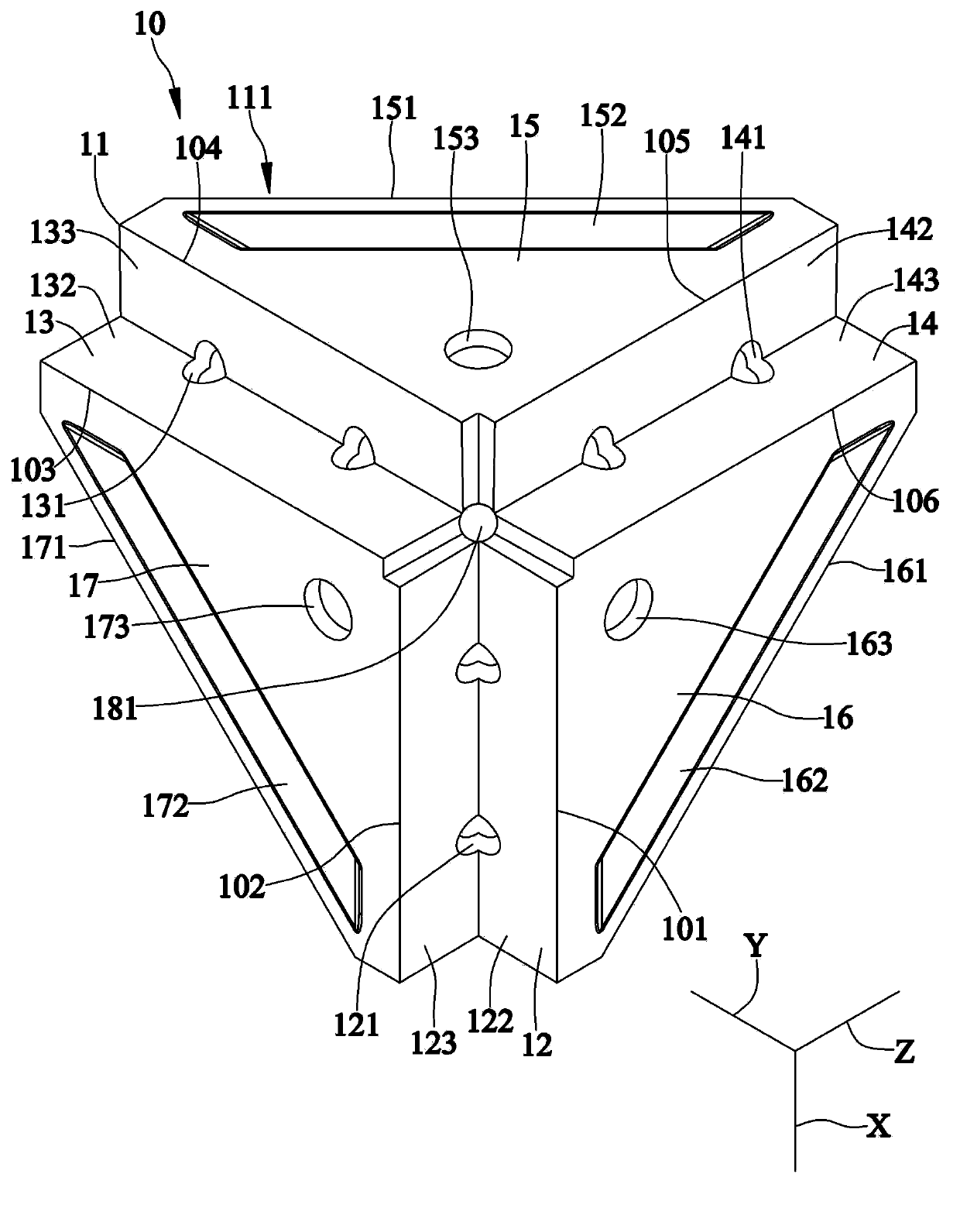

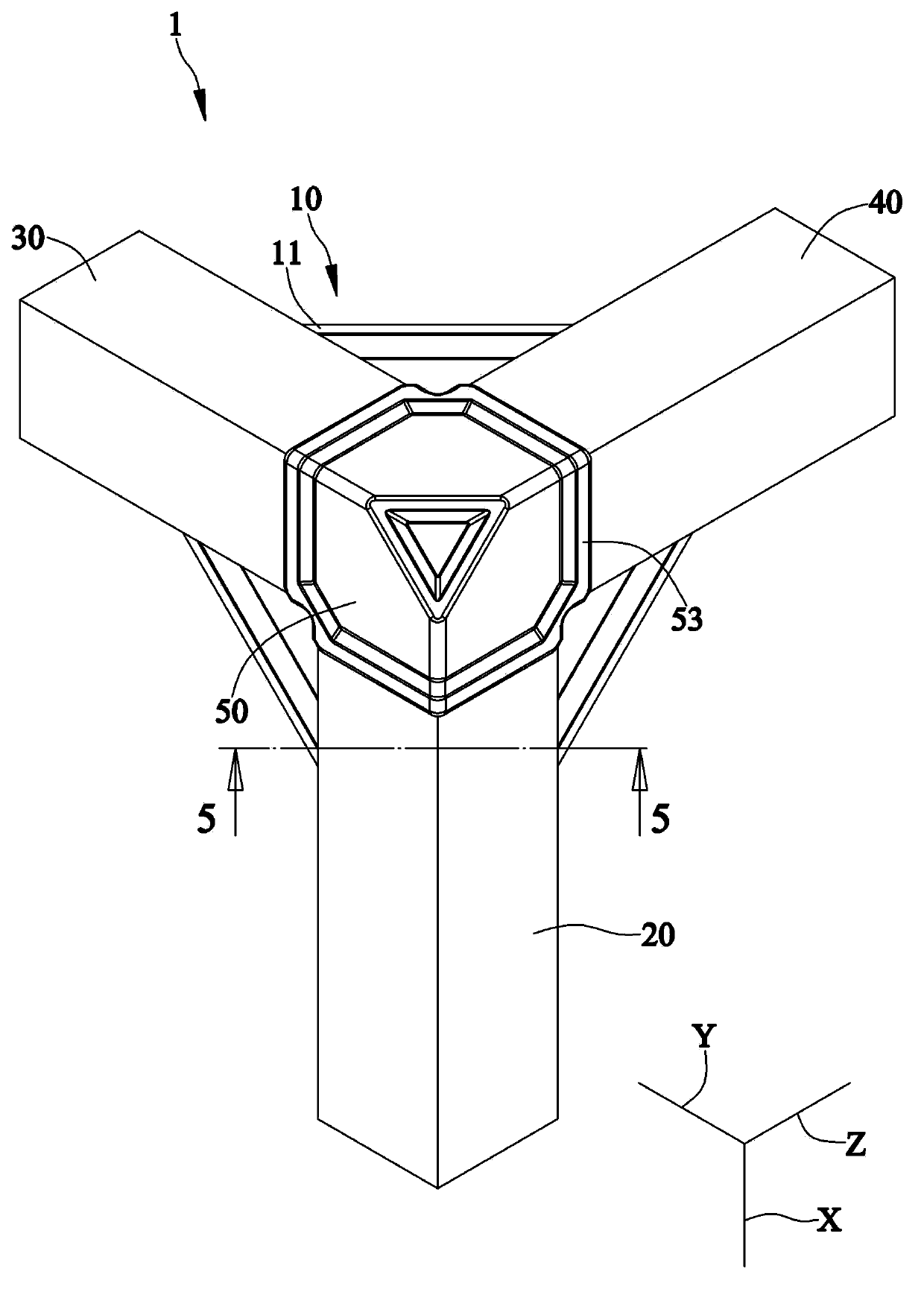

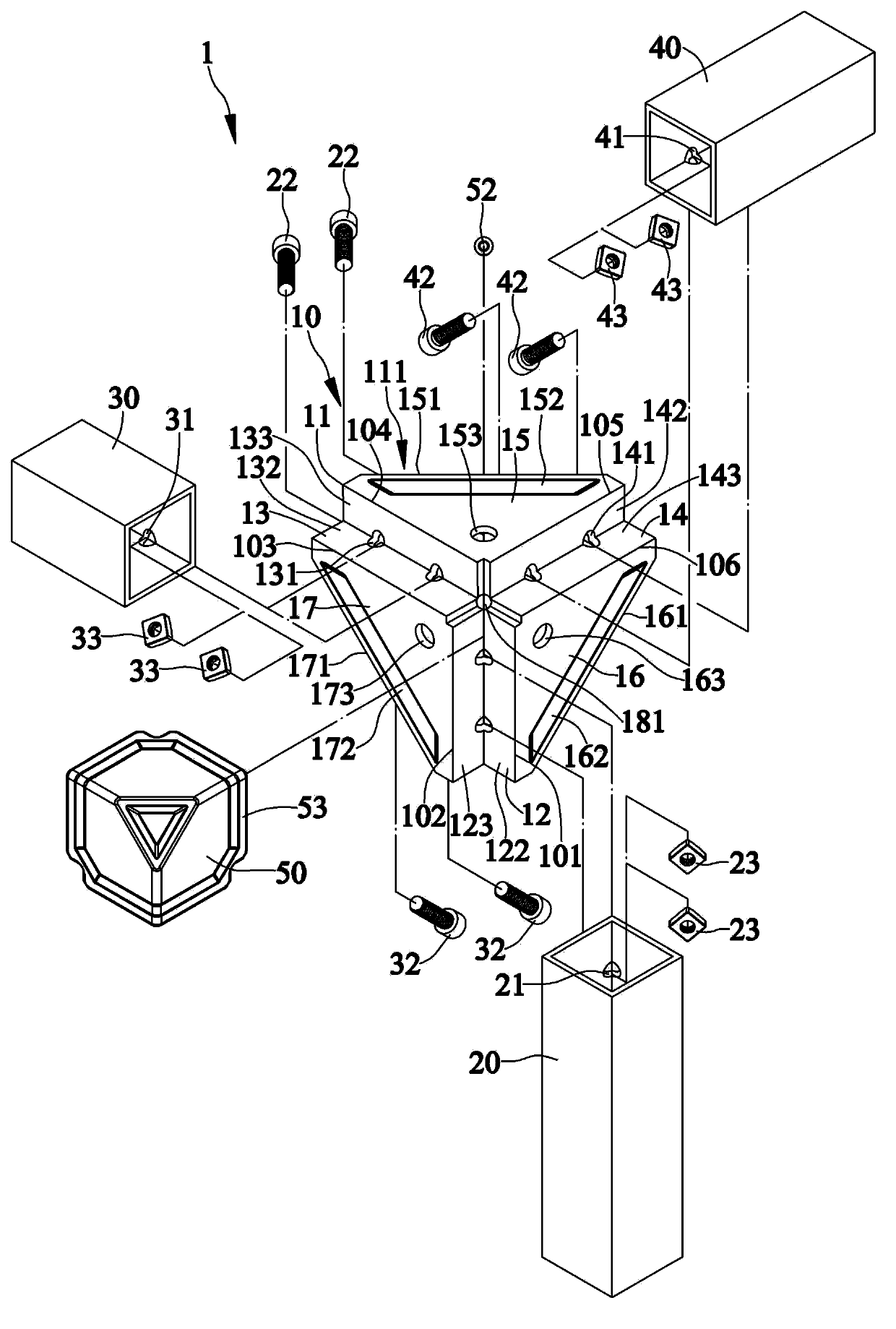

[0026] refer to Figure 1 to Figure 6 , is the joint of the assembly frame of the present invention and the first embodiment of the assembly frame formed by using it. figure 1 It is a three-dimensional appearance view of the joint of the assembly frame of the present invention, Figure 2 to Figure 6 It is a schematic structural diagram of the assembly frame formed by the joint according to the present invention. The assembly frame 1 includes the joint 10 , at least one first frame 20 , at least one second frame 30 and at least one third frame 40 . The joint 10 includes a body 11; wherein:

[0027] The body 11 has a first side 111 and a second side 112 opposite to each other. The first side 111 of the body 11 has a first receiving groove 12, a second receiving groove 13 and A third accommodating groove 14. The first accommodating groove 12 extends along a first axis X, the second accommodating groove 13 extends along a second axis Y, the second axis Y is perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com