Light guide plate installing structure

A technology of installation structure and light guide plate, which is applied in the direction of optics, light guide, light source, etc., can solve the problems of inaccurate positioning of light guide plate, easy damage during installation, and short service life, so as to reduce the risk of light source being crushed and guarantee Normal use, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

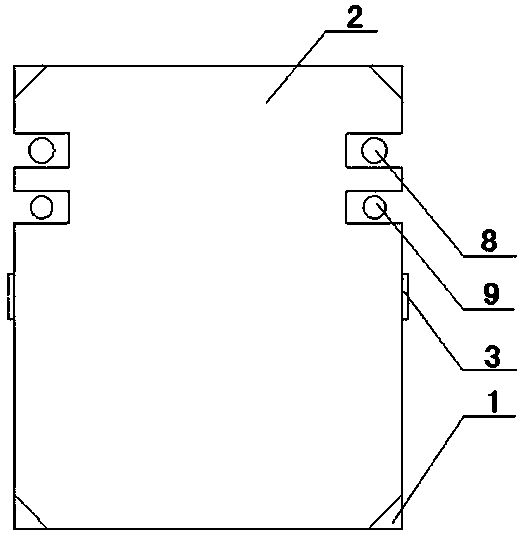

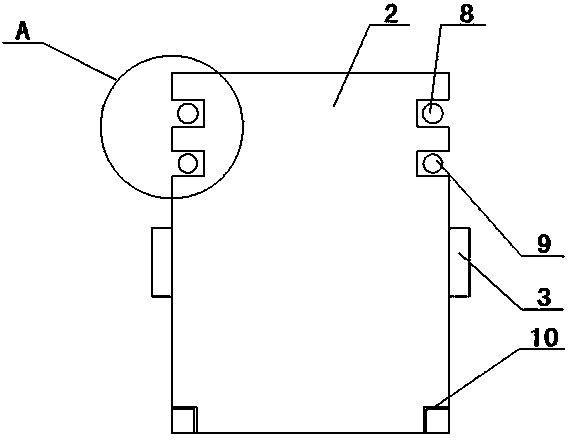

[0028] The invention proposes a light guide plate installation structure, which includes a light guide plate, a back plate and a plastic frame arranged in sequence. The light guide plate includes a first surface and a second surface oppositely arranged, and the second surface faces the back plate, such as figure 1 As shown, the four corners of the first surface of the light guide plate 2 are provided with downwardly recessed clamping positions 1 , and the side walls of the middle part of the light guide plate 2 are provided with outwardly protruding lugs 3 .

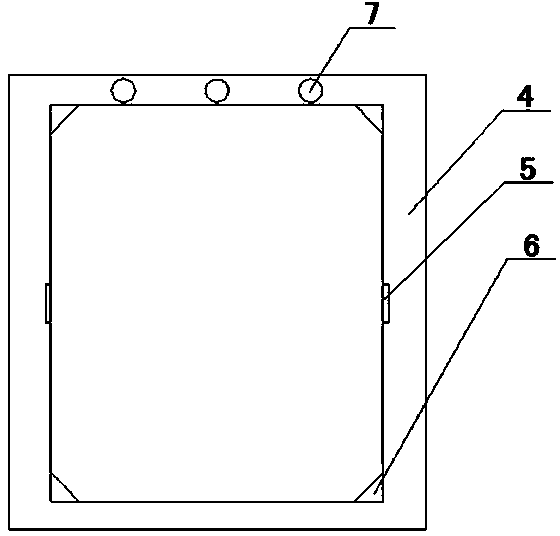

[0029] like figure 2 As shown, the four corners of the inner ring of the plastic frame 4 are provided with ribs 6 matching with the clamping positions 1 , and the middle part of the inner ring of the rubber frame 4 is provided with a positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com