Shuttle-shaped blade device for automobile coating plant

A blade and shuttle-type technology, which is applied in the field of shuttle-type blade devices for automobile painting workshops, can solve the problems of blade vibration, low strength of straight blades, and large forward wind pressure, so as to improve the strength of blades and solve the problem of easy vibration or damage , Reduce the effect of positive wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

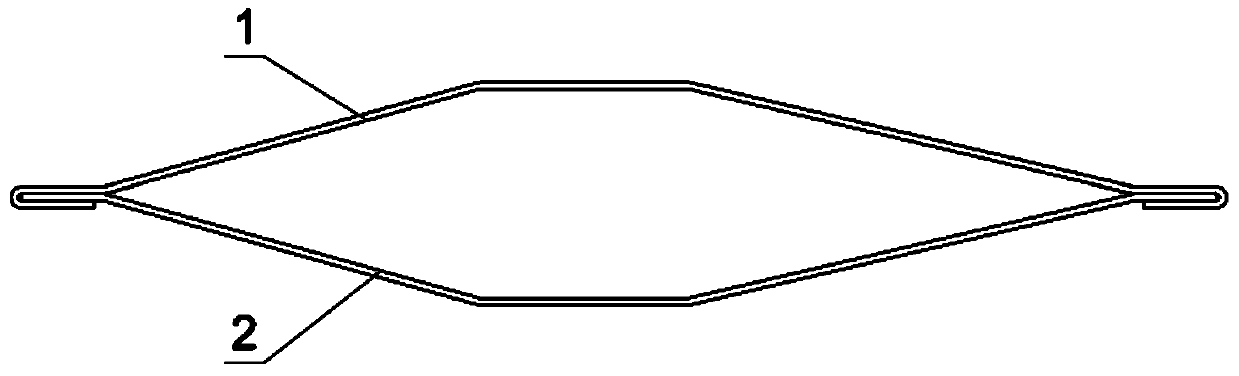

[0023] like Figure 1~3 As shown, a shuttle-type blade device for an automobile painting workshop includes a blade shell and an end cover 3; the blade shell is a shell with a shuttle-shaped inner cavity formed by assembling the first blade 1 and the second blade 2 body;

[0024] The first blade 1 and the second blade 2 are respectively connected by the blade of the horizontal section, the blade of the inclined section connected with the two ends of the blade of the horizontal section and the assembly structure connected with the end of the blade of the inclined section; the first blade 1 and the second blade The blade 2 has an asymmetrical shuttle structure; this structure improves the strength of the blade, reduces the positive wind pressure of the blade when switching, and solves the problem that the blade is easy to vibrate or be damaged in the prior art.

[0025] The assembly structure of the first blade 1 includes a straight section and a bent section connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com